Friction-type quality turning wheel damper

A technology of dampers and runners, which is applied in the direction of building types, building components, building structures, etc., can solve the problems of poor post-earthquake reset ability, small application range, and small overall output, and achieve strong self-adaption and shock absorption Good effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

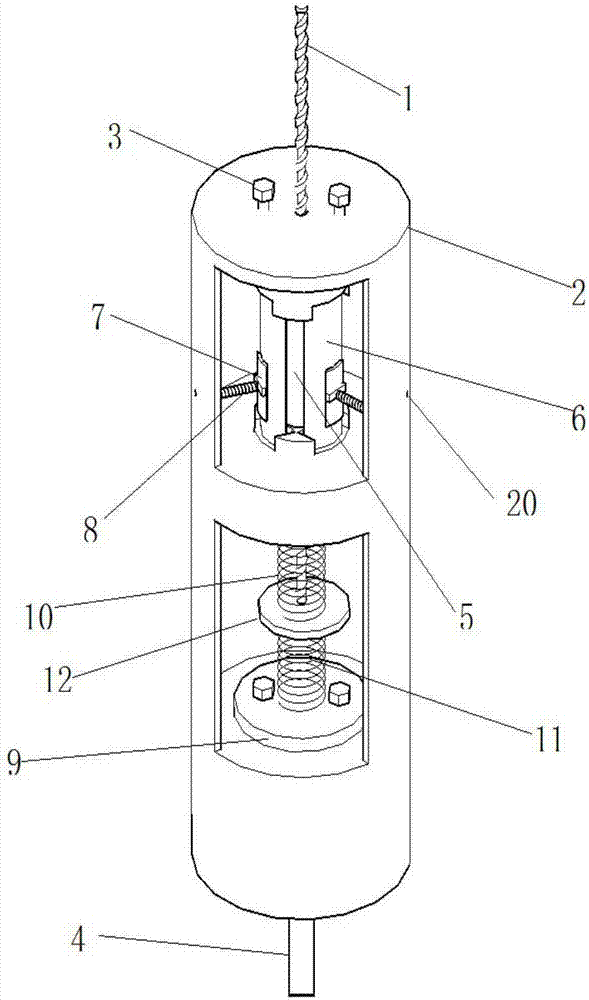

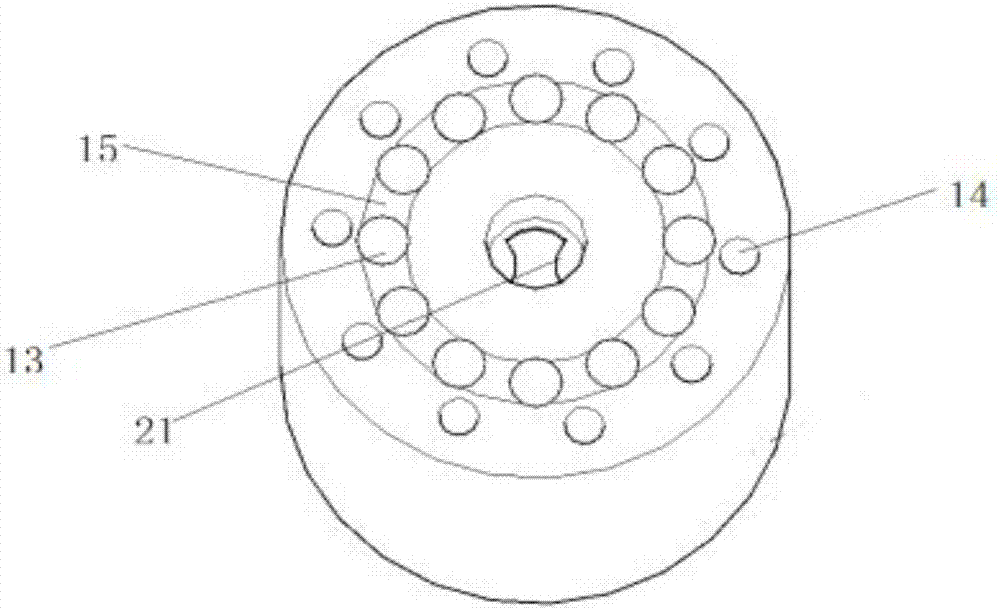

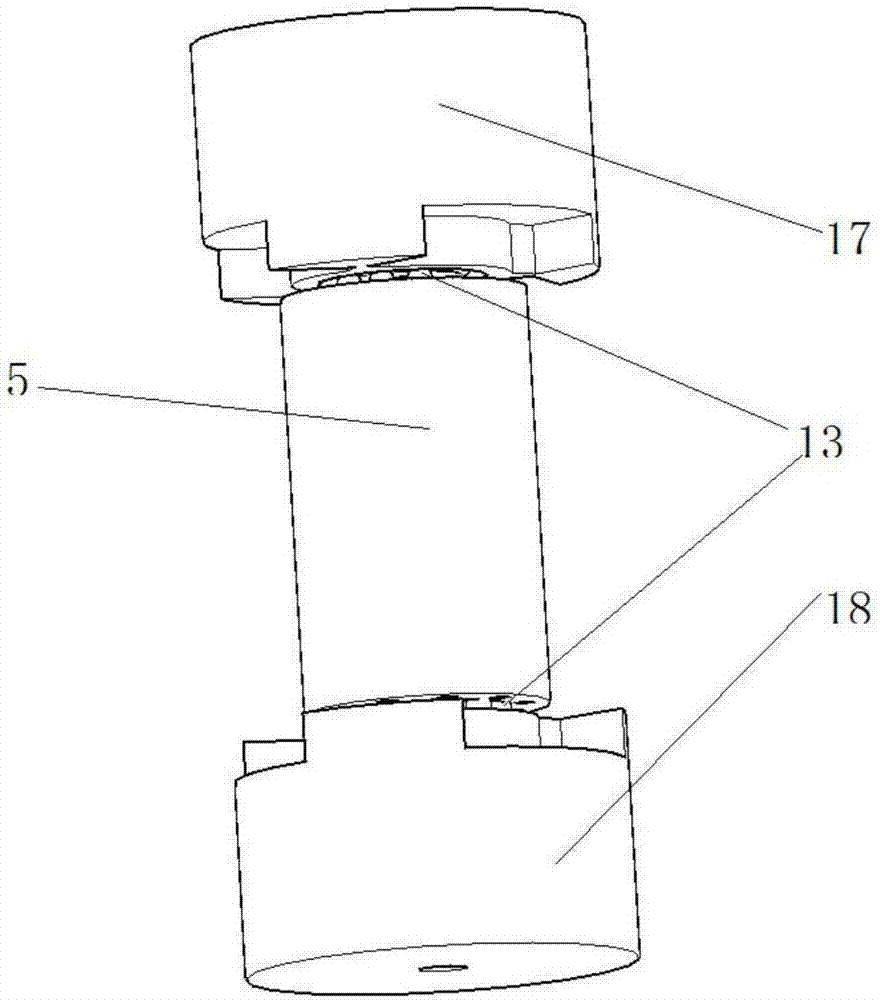

[0029] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , a friction-type mass runner damper, including a high-strength shell 2, the top of the inner cavity of the high-strength shell 2 is connected with an upper positioning pressure bearing body 17 through bolts 3, and bears the force transmitted by the mass runner 5 together with the high-strength shell 2; The lower end surface of the upper positioning pressure bearing body 17, the upper and lower end surfaces of the mass runner 5, and the upper end surface of the lower positioning pressure bearing body 18 are provided with a circular groove 15, and the inside of the circular groove 15 is provided with a ball 13, and the lower positioning pressure bearing body 18 is completely The side is welded on the inner surface of the high-strength shell 2; the upper positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com