Production method for comprehensive recovery of antimony-rich gold concentrates

A production method and technology of gold concentrate, which is applied in the field of comprehensive recovery of antimony-rich gold concentrate, can solve problems such as the difficulty of element separation and recovery, and achieve the effects of improving extraction purity, preventing coal ash from entering, and preventing cost increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

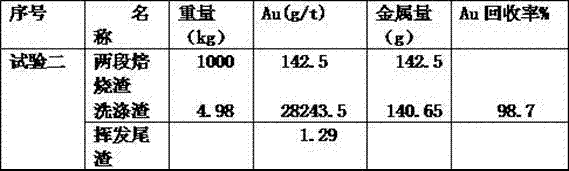

Examples

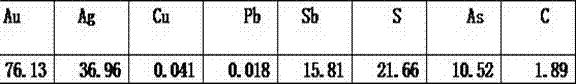

Embodiment 1

[0029] 1) Prepare the mixed solution: add the antimony-containing gold concentrate to the solution of hydrochloric acid and water at a mass ratio of 1:5, add the leaching agent ferric chloride, and heat to 90°C to obtain the mixed solution;

[0030] 2) Preparation of chlorinated slag and antimony-enriched leaching solution: pass chlorine gas into the mixed solution obtained in step 1), keep the potential of the mixed solution at 300-350mv, leach for 2 hours at a temperature of 90°C, and filter to obtain chlorinated slag and antimony-rich leachate;

[0031] Wherein utilize antimony-rich leaching solution to prepare antimony powder and carry out according to the following steps:

[0032] a) Prepare heated antimony-rich leaching solution: heat the antimony-rich leaching solution to 60°C to obtain a heated antimony-rich leaching solution;

[0033] b) Preparation of antimony powder and reducing solution: Add iron powder into the heated antimony-rich leaching solution prepared in s...

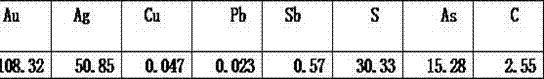

Embodiment 2

[0041] 1) Preparation of mixed solution: add antimony-containing gold concentrate to a solution of hydrochloric acid and water at a mass ratio of 1:5, add ferric chloride as a leaching agent, and heat to 95°C to obtain a mixed solution;

[0042] 2) Preparation of chlorinated slag and antimony-enriched leaching solution: pass chlorine gas into the mixed solution obtained in step 1), keep the potential of the mixed solution at 300-350mv, leach for 2 hours at a temperature of 95°C, and filter to obtain chlorinated slag and antimony-rich leachate;

[0043] Wherein utilize antimony-rich leaching solution to prepare antimony powder and carry out according to the following steps:

[0044] a) Prepare heated antimony-rich leaching solution: heat the antimony-rich leaching solution to 60°C to obtain a heated antimony-rich leaching solution;

[0045] b) Preparation of antimony powder and reducing solution: Add iron powder into the heated antimony-rich leaching solution prepared in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com