Method used for producing acidic cellulase via solid fermentation of forestry and agricultural residues with inonotus obliquus

A technology of acid cellulase and agricultural and forestry waste, applied in the direction of enzymes, microorganism-based methods, enzymes, etc., can solve the problems of limited application range, low enzyme production capacity, unstable quality, etc., to reduce costs, improve the environment, Energy and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] A process for producing acid cellulase by utilizing Inonotus obliquus for solid fermentation of agricultural and forestry waste, comprising the steps of:

[0040] (1) Strain activation: use Inonotus obliquus as the strain (commercially available), inoculate it on the slant strain culture medium to obtain activated strain; the formula of the slant strain culture medium is: malt extract 40 g / 100mL, peptone 4 g / 100mL, agar 10 g / 100mL, pH value 5.4-5.6, the parameters for culture on the slant culture medium are: temperature 27-28 ℃, culture 200-250 hours.

[0041] (2) Liquid strain culture: transfer the activated strain into the seed culture medium, and cultivate the liquid strain for 3 days on a shaker at 28°C with a shaker speed of 150 rpm; the composition of the seed culture medium is: K H 2 PO 4 0.3g, MgSO 4 0.2 g, 3 g of yeast extract, 0.5 g of peptone, 10 g of glucose, 1000 mL of distilled water, natural pH, sterilized at 121 ° C for 20 min.

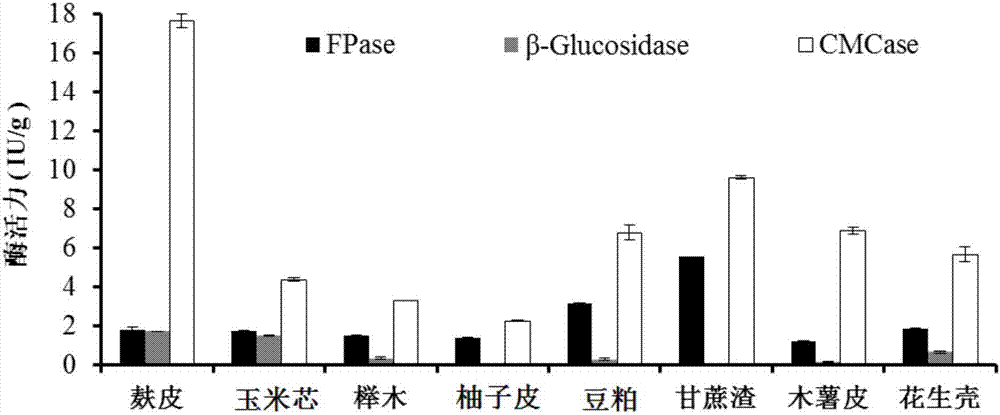

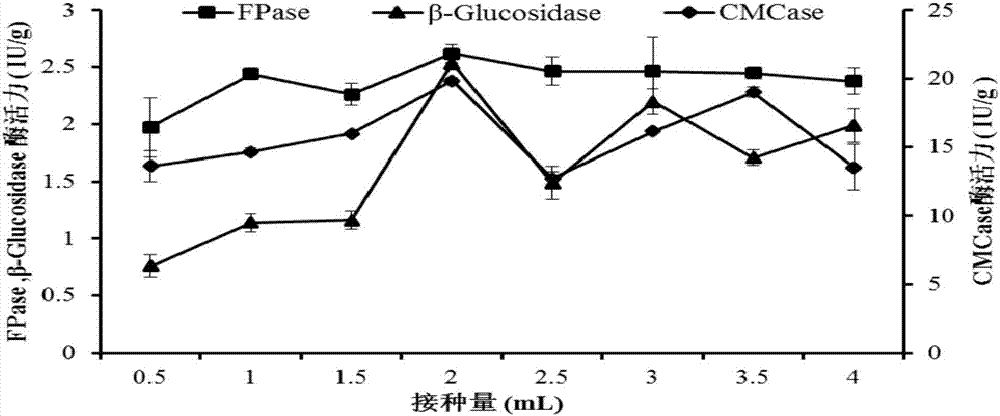

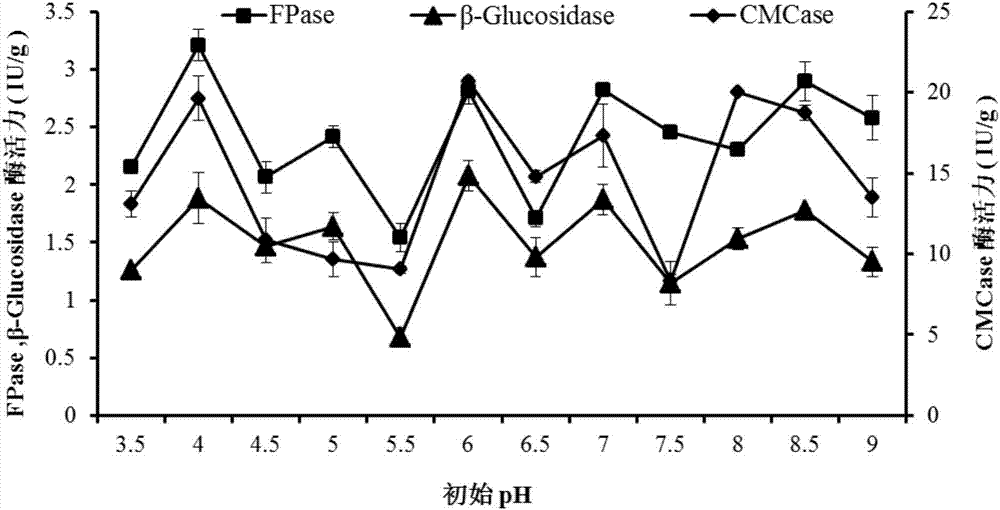

[0042](3) Solid fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com