A kind of high antistatic property coating and preparation method thereof

An electrostatic and high-performance technology, which is applied in the field of high antistatic performance coatings and its preparation, can solve problems such as poor conductivity and partial discharge, and achieve the effects of improving adhesion performance, increasing durability, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

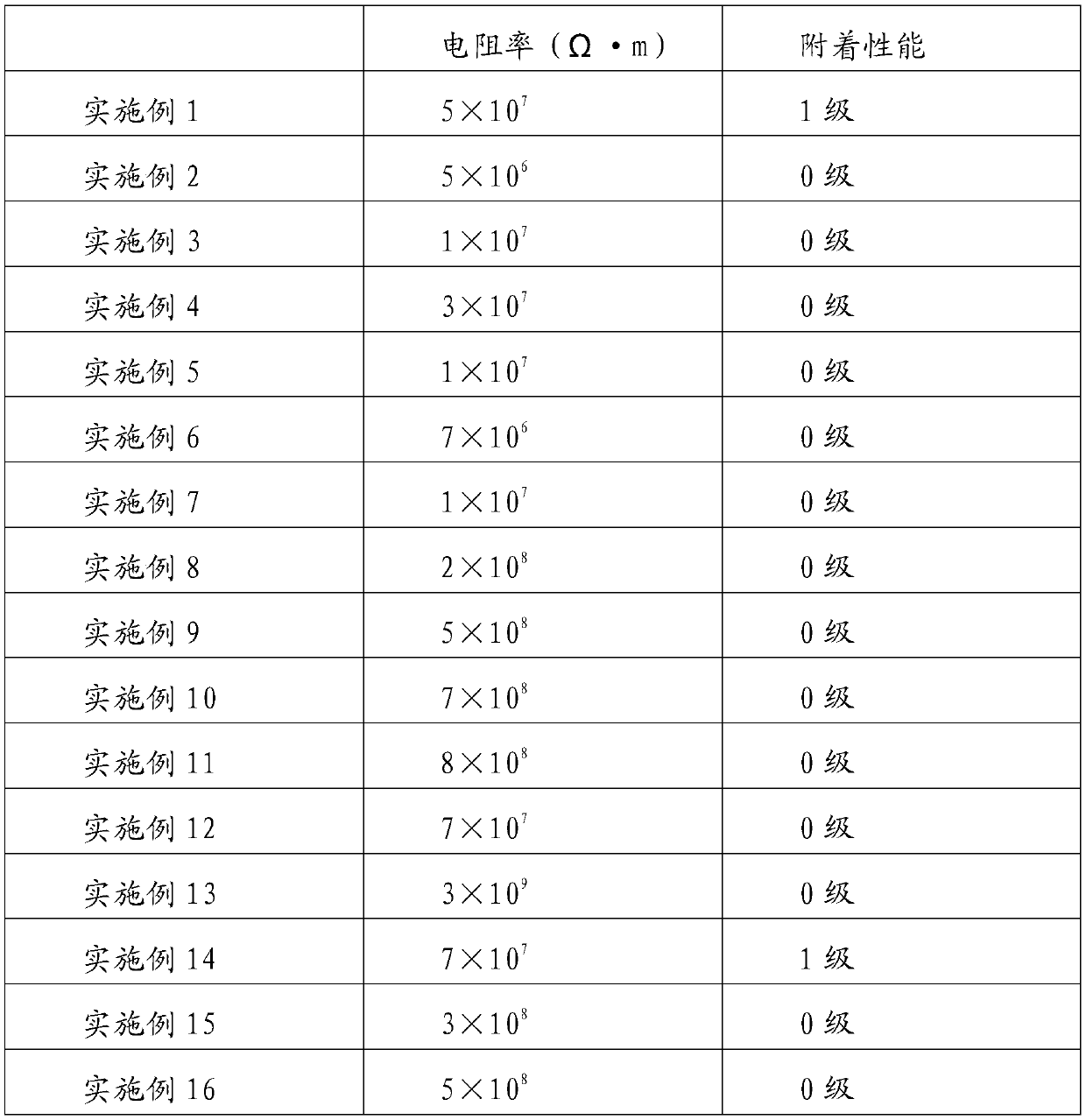

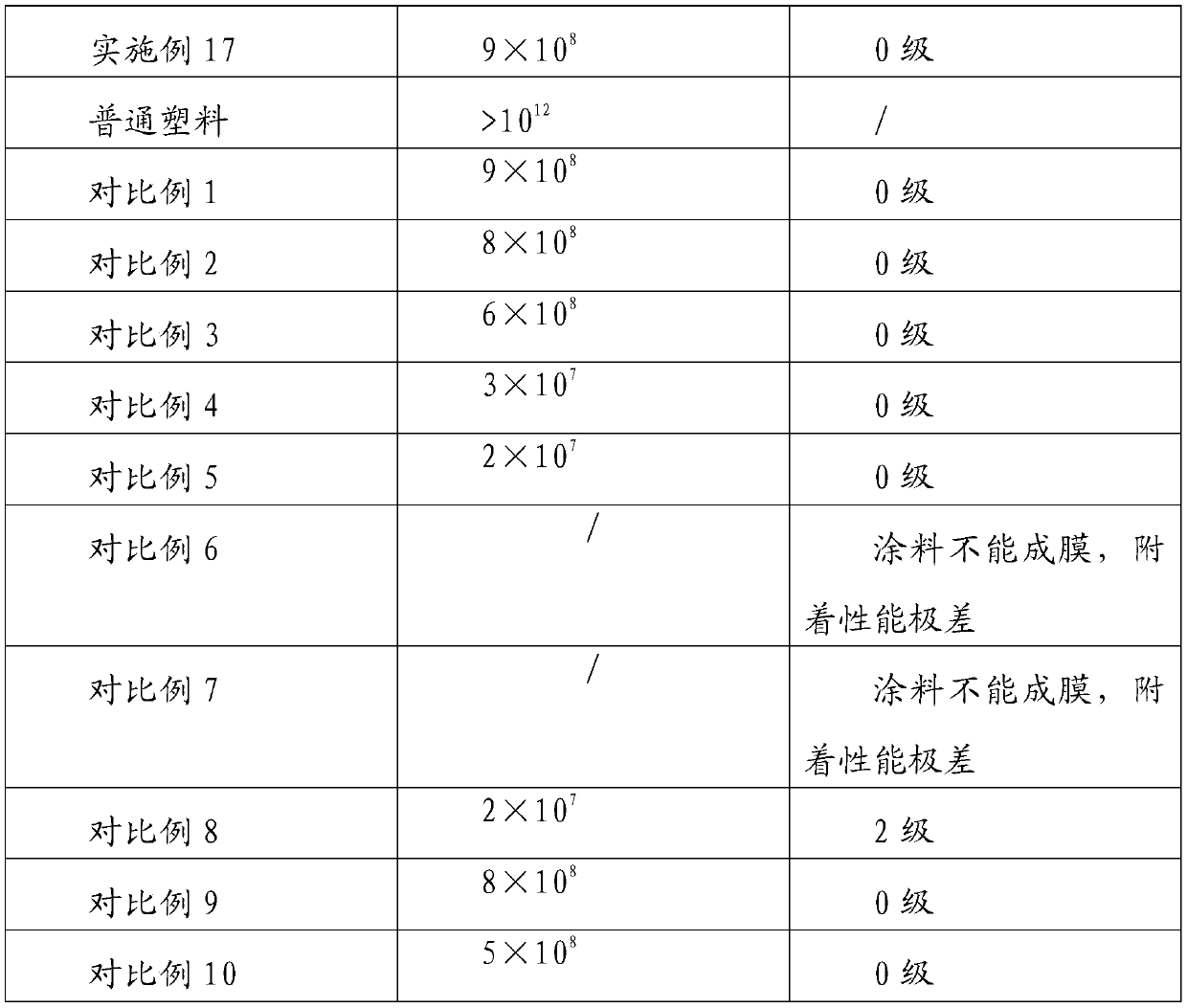

Examples

preparation example Construction

[0062] The preparation method of the above-mentioned high antistatic performance coating includes the following steps: mixing the components together according to the above-mentioned proportion.

[0063] When the auxiliary agent includes an adhesion promoter, a wetting and dispersing agent and a defoamer, the preparation method of the high antistatic performance coating can specifically adopt the following steps to prepare:

[0064] (1) Preparation of wet dispersion system:

[0065] Mix the wetting and dispersing agent with the solvent in proportion to obtain a wetting and dispersing system;

[0066] (2) Preparation of conductive system:

[0067] Add conductive filler in proportion to the wetting dispersion system obtained in step (1), and mix to obtain a conductive system;

[0068] (3) Preparation of high antistatic performance coatings:

[0069] Add defoamer and nano-sol in proportion to the conductive system obtained in step (2), mix, then add conductive additive and adh...

Embodiment 1

[0082] The high antistatic performance paint consists of the following components by weight: multilayer graphene conductive filler is 1.8 kg, Hostastat HS1 conductive additive is 1.5 kg, SiO 2 / TiO 2 Nano-sol is 45 kg, solvent (i.e. isopropanol) is 50.7 kg, DOW CORNING 2-6040 adhesion promoter is 0.3 kg, Efka-701 wetting and dispersing agent is 0.4 kg, 082 defoamer is 0.3 kg.

[0083] The preparation method of this high antistatic performance coating is as follows:

[0084] (1) Preparation of wet dispersion system:

[0085] At room temperature, add 0.4 kg of Efka-701 wetting and dispersing agent and 50.7 kg of isopropanol solvent into the reactor, stir at a low speed of 100 r / min to dissolve the two, and obtain a wetting and dispersing system;

[0086] (2) Preparation of conductive system:

[0087] At room temperature, add 1.8 kilograms of multilayer graphene conductive fillers to the wet dispersion system obtained in step (1), and stir at 1200r / min for 10min to obtain a co...

Embodiment 2

[0091] The high antistatic performance coating includes the following components by weight: 0.3 kg for monolayer graphene conductive filler, 1.5 kg for Hostastat HS1 conductive additive, SiO 2 / TiO 2 Nano sol is 45 kg, solvent (isopropanol) is 52.2 kg, DOW CORNING 2-6040 adhesion promoter is 0.3 kg, Efka-701 wetting and dispersing agent is 0.4 kg, 082 defoamer is 0.3 kg.

[0092] The preparation method of this high antistatic performance coating is as follows:

[0093] (1) Preparation of wet dispersion system:

[0094] At room temperature, add 0.4 kg of Efka-701 wetting and dispersing agent and 52.2 kg of isopropanol solvent into the reactor, stir at a low speed of 100 r / min to dissolve the two, and obtain a wetting and dispersing system;

[0095] (2) Preparation of conductive system:

[0096] At room temperature, add 0.3 kg of single-layer graphene conductive filler to the wet dispersion system obtained in step (1), and stir at 1000r / min for 10min to obtain a conductive sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com