Method and device for transforming mechanical packed tower into jet flow spray energy-saving tower structure

A structural method and technology of packed towers, which are applied in the directions of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problem of reduced acceptance of industrial application and promotion of jet spray energy-saving cooling towers, unacceptable by users, The problem of high construction cost has the effect of accelerating the pace of energy-saving renovation, solving the problem of cooling effect attenuation, and eliminating the pain point of investment recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

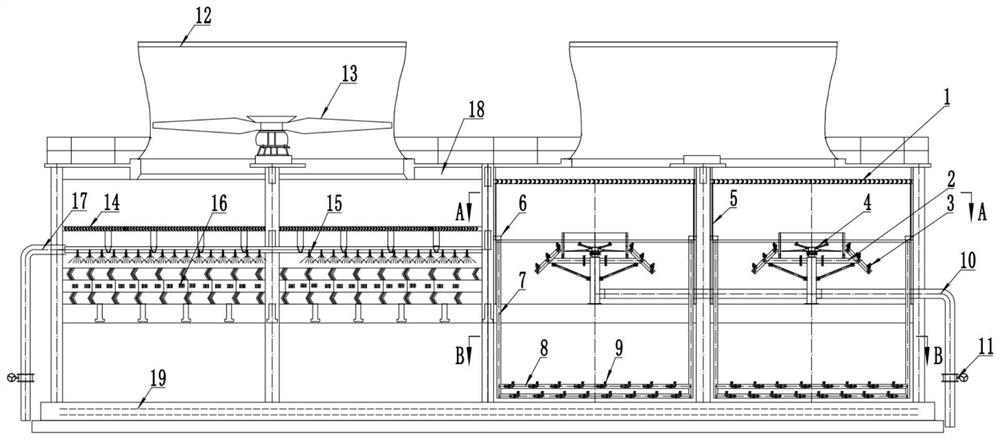

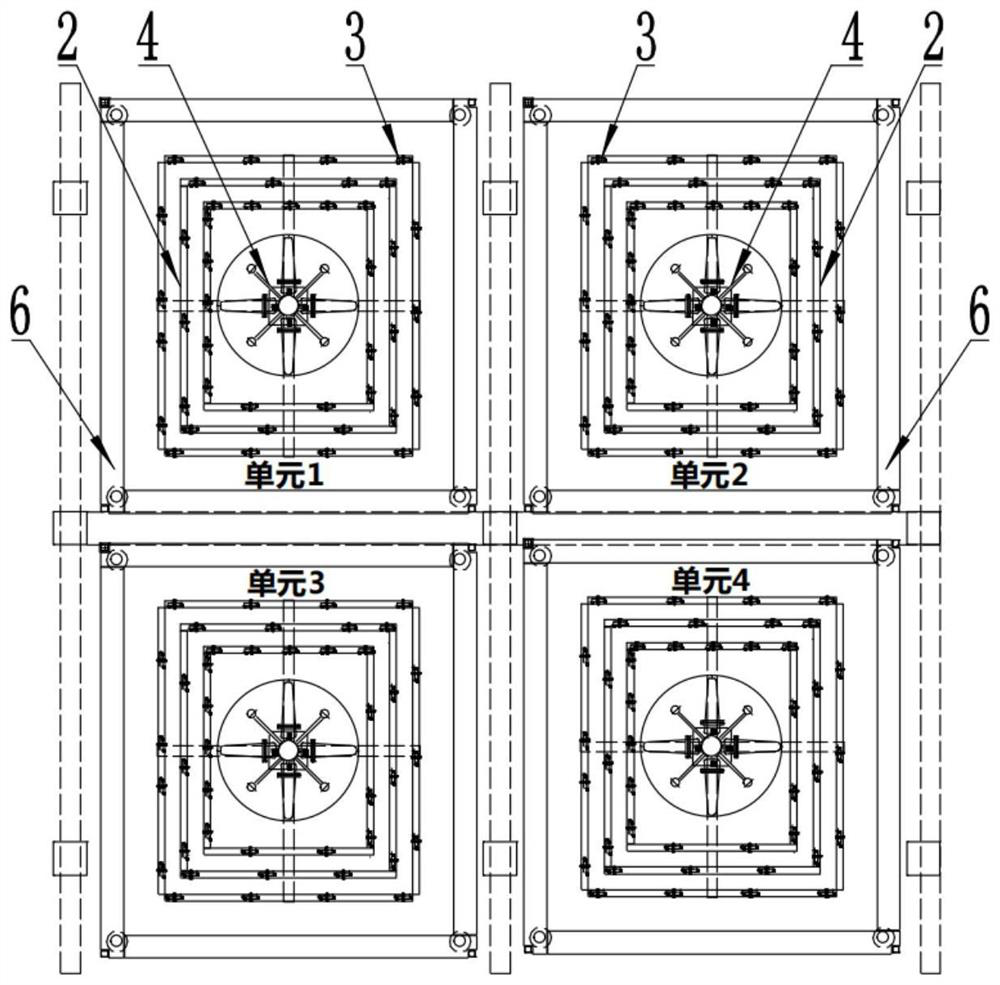

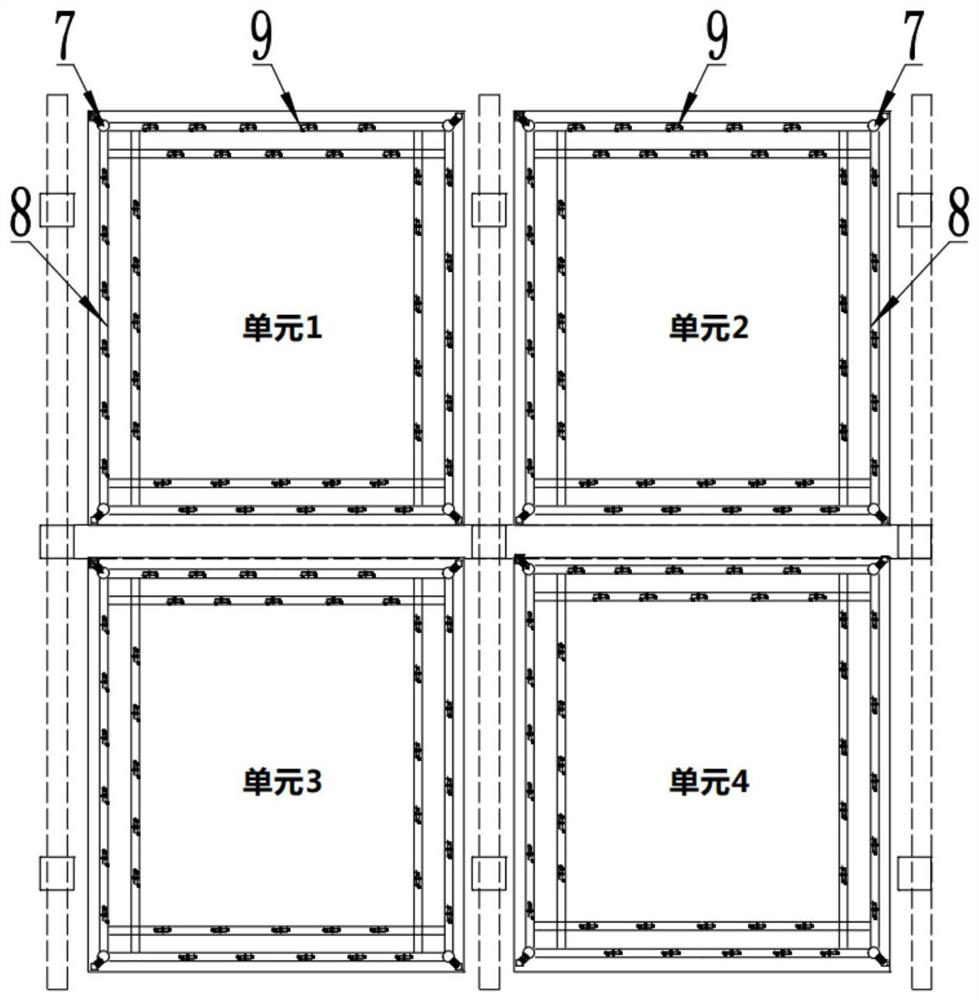

[0035] see Figure 1-12 , the present invention provides a technical solution: a structural method and device for transforming a mechanical packing tower into a jet spray energy-saving tower, including a special water collector 1 for a jet spray tower, a primary swirling atomization + a fixed atomization water distribution pipeline system 2. Special nozzle head for primary and medium-low pressure swirl atomization 3. Swirl atomization propulsion device 4. Prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com