High-speed dense-arrangement wire winding machine used for wire and composite in-channel superconducting wire material

A superconducting wire rod and wire take-up technology is applied in the field of wire take-up to achieve the effects of solving unstable control, ensuring wire arrangement accuracy, and preventing left-right deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

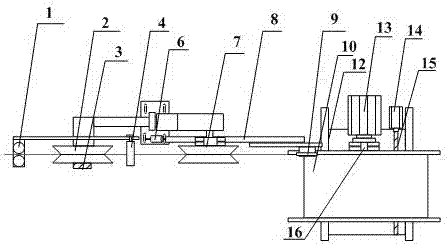

[0017] The structural principle and working principle of the patent of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] see figure 1 , 2 , the present invention is used for the take-up function of flat tape and superconducting wire with composite mosaic structure, including a line-entry system, a rotation servo system controlled by stable torque, and a traversing platform servo system controlled by high-precision displacement;

[0019] The incoming line system includes an incoming line structure support 11, and one side of the incoming line structure support 11 is provided with an incoming line guide wheel 1, a speed measuring wheel 2, an incoming line guide bracket 5, a counterweight weight 6, and an incoming line angle adjustment wheel 7. The crimping arm 8, the wire crimping device 9, and the wire crimping wheel 4 installed on the wire guide bracket 5 and the line speed detection encoder 3 installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com