Semi-automatic unloading device and unloading equipment

A kind of unloading device and semi-automatic technology, which is applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of high work intensity and low unloading efficiency, achieve the effect of reducing work intensity, improving unloading speed, and avoiding the action of moving goods up and down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

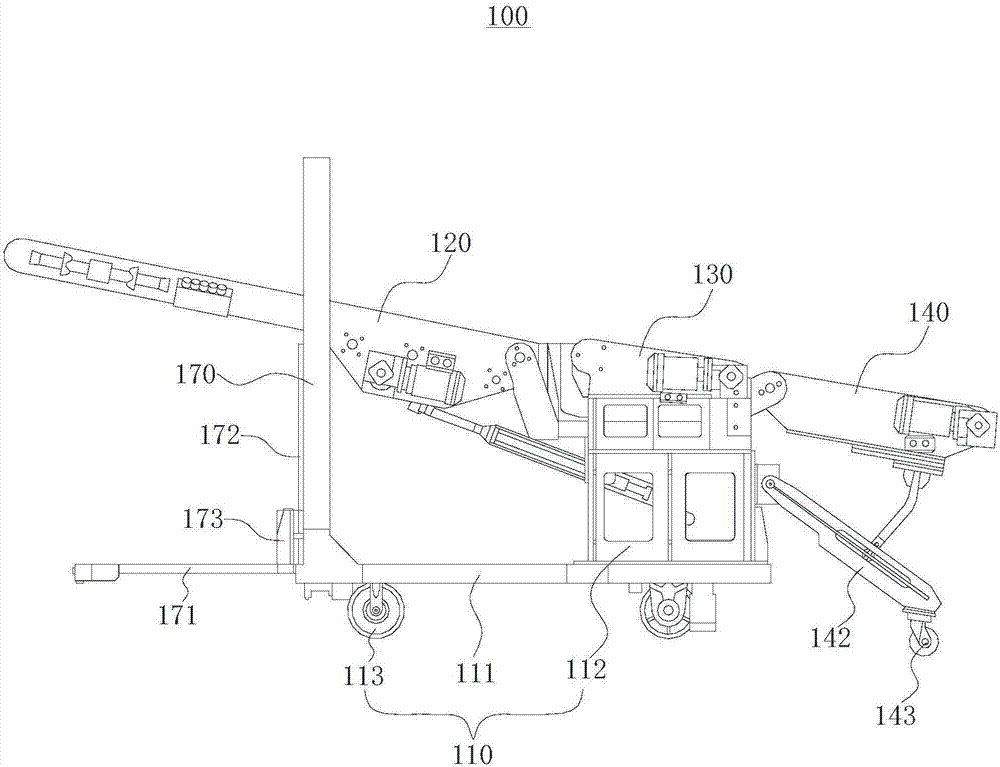

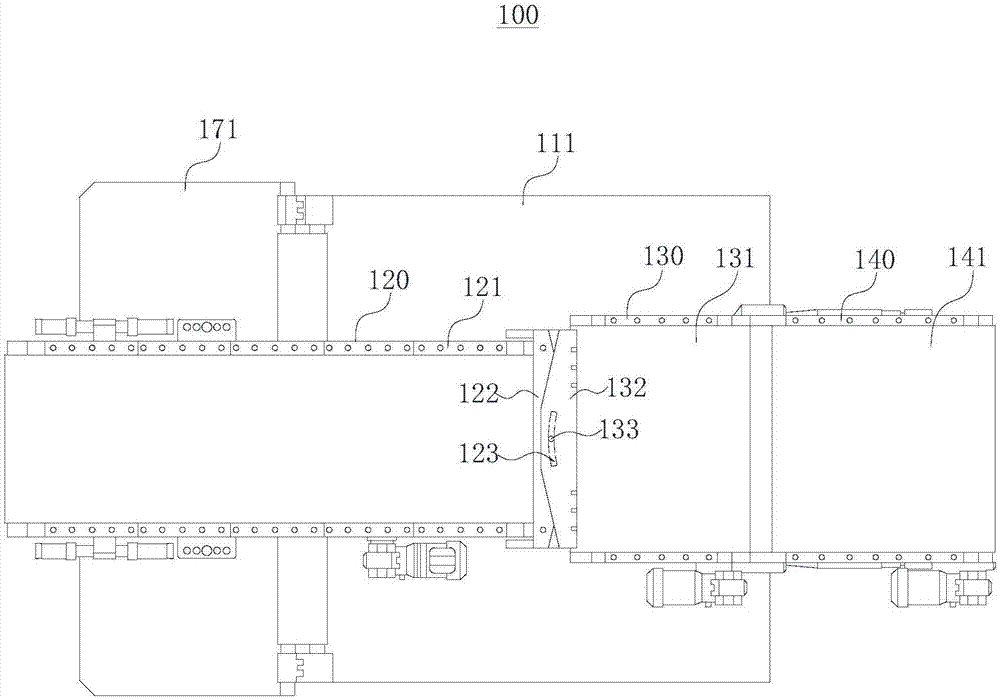

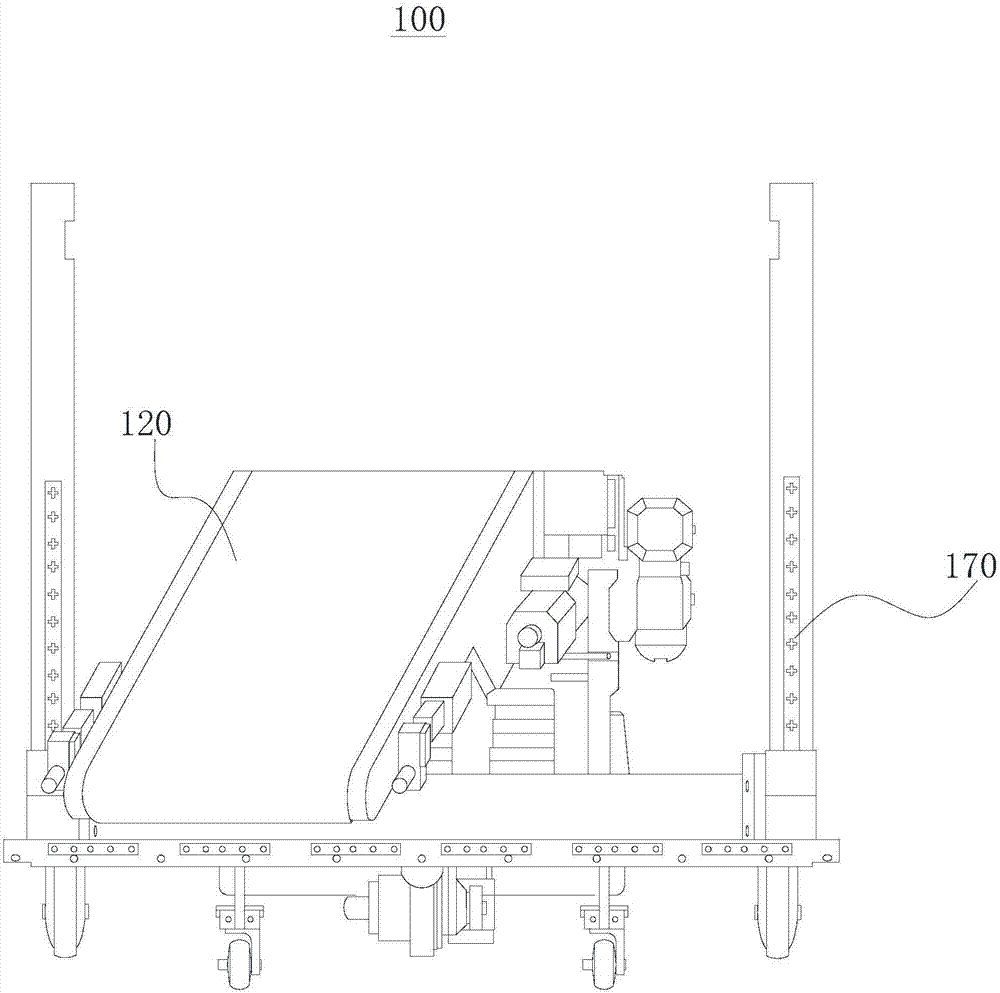

[0032] Please refer to figure 1 , the present embodiment provides a semi-automatic unloading device 100 , which includes a car body 110 , a first frame 120 , a second frame 130 , a third frame 140 and a lifting frame 170 .

[0033] In this embodiment, the structure of the vehicle body 110 will be described first, and its structure is as follows: the vehicle body 110 includes a base plate 111 and a control box 112, the control box 112 is installed on the base plate 111, and a plurality of wheels 113 are installed on the bottom of the base plate 111 , the control box 112 can control the rotation of the wheels 113, thereby controlling the movement of the vehicle body 110. The first frame 120 , the second frame 130 , and the third frame 140 are all installed on the control box 112 , and the lifting frame 170 is installed on the bottom plate 111 .

[0034] Next, the structures of the first rack 120 , the second rack 130 and the third rack 140 and their mutual connections will be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com