Belt conveyor monitoring system based on Ethernet

A belt conveyor and monitoring system technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problem of inability to realize loudspeaker broadcasting and voice alarm, and inability to realize frequency conversion and speed regulation based on coal flow, monitoring system Problems such as vibration cannot be monitored in real time to achieve a good human-computer interaction interface, convenient function expansion and modification, and enhanced system stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

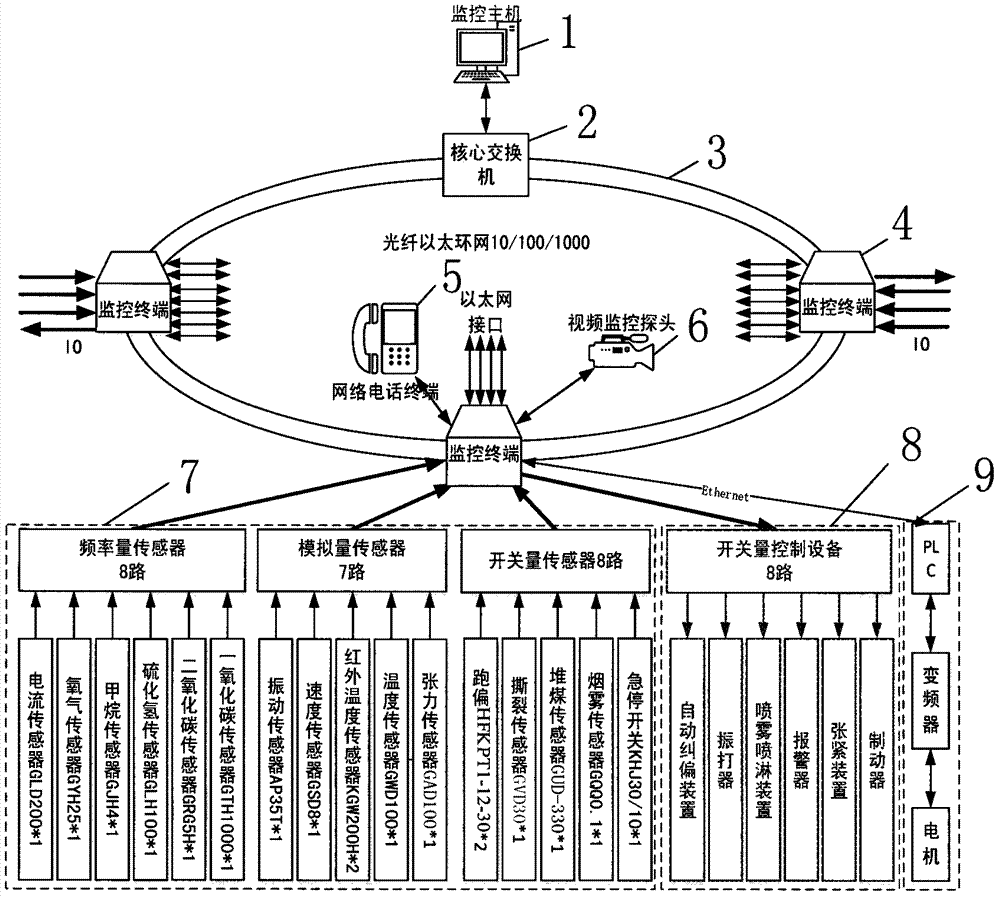

[0034] figure 1 Among them, 1. Monitoring host; 2. Core switch; 3. Optical fiber communication ring network; 4. Monitoring terminal; 5. Internet phone terminal; 6. Video monitoring probe; Motor frequency conversion control device.

[0035] figure 2 Middle, 7-1, current sensor; 7-2, oxygen sensor; 7-3, methane sensor; 7-4, hydrogen sulfide sensor; 7-5, carbon dioxide sensor; 7-6, carbon monoxide sensor; 7-7, vibration Sensor; 7-8, speed sensor; 7-9, infrared temperature sensor; 7-10, temperature sensor; 7-11, tension sensor; 7-12, deviation sensor; 7-13, tear sensor; 7-14 , Heap coal sensor; 7-15, smoke sensor; 7-16, emergency stop switch.

[0036] According to the accompanying drawings, the Ethernet-based belt conveyor monitoring system designed by the present invention consists of: monitoring host 1; core switch 2; optical fiber communication ring network 3; monitorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com