Oil sludge 3D printer

A 3D printer and sludge technology, which is used in ceramic molding machines, processing and manufacturing, and liquid material additive processing. It can solve the problems of complex procedures, blank markets, and many tools, and achieve flow control, reduce labor costs, and reduce costs. effect of spending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

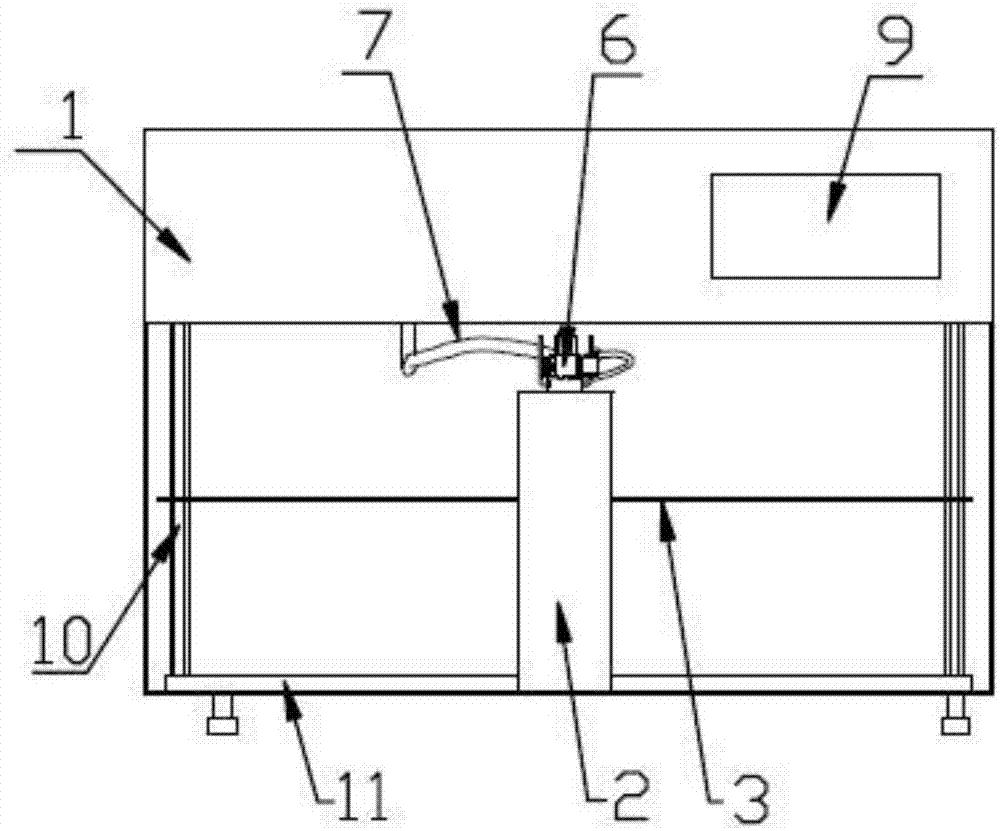

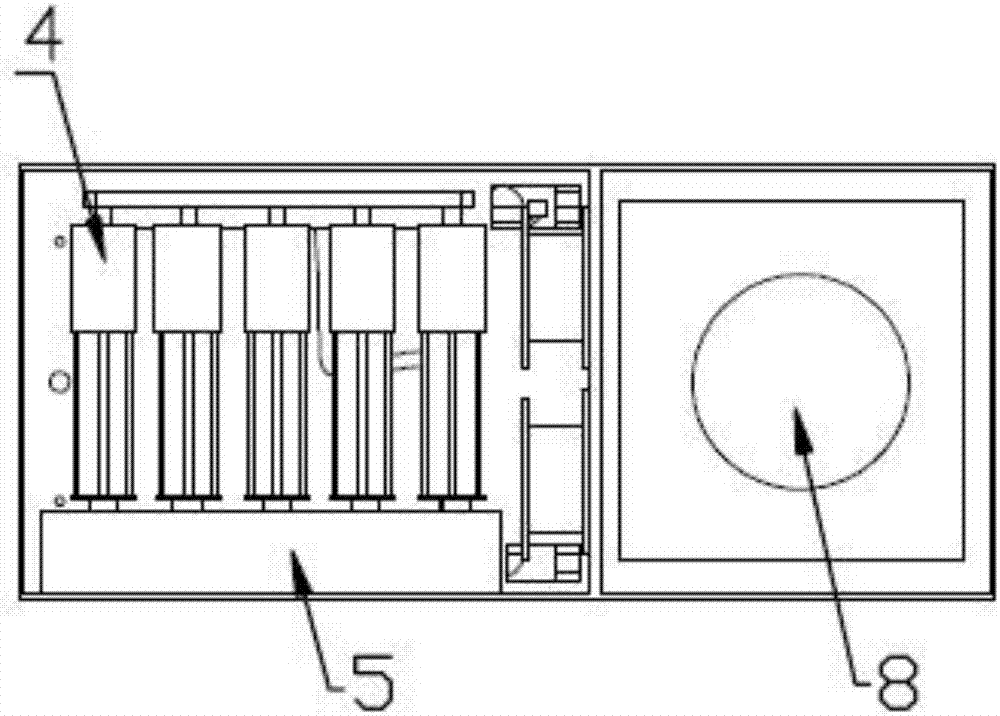

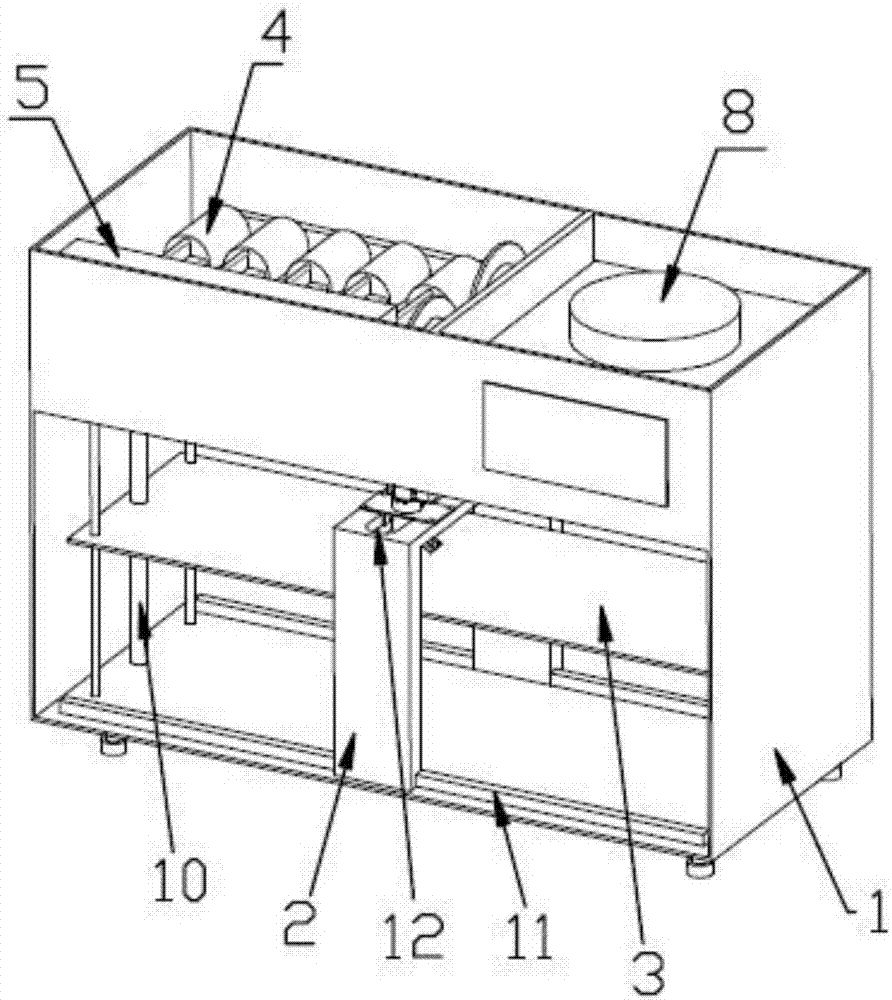

[0035] Such as Figure 1-3 As shown, a sludge 3D printer includes a box body 1, a gantry frame 2, a workbench 3, 5 sludge barrels 4, a motor-driven material system 5, a print head 6, a material pipe 7, a waste purification system 8 and an industrial computer 9. There are two parallel X-axis guide rails 11 on the bottom of the box body 1, two vertical Z-axis guide rails 10 on both ends of the box body 1, the gantry 2 is set on the X-axis guide rails 11, and the workbench 3 Both ends are connected with the Z-axis guide rail 10, and the workbench 3 is located under the top of the gantry 2, the oil sludge barrel 4 is arranged on the upper part of the box body 1, and the motor-driven material system 5 is arranged on the upper part of the box body 1 and is connected with the oil sludge barrel 4 is connected to one end, the other end of the oil sludge barrel 4 is connected to the material pipe 7, the print head 6 is arranged on the top of the gantry 2, the oil sludge barrel 4 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com