Automatic Wasabi Grinder

A grinder and wasabi technology, which is applied in the field of automatic wasabi grinder, can solve the problems of low production efficiency, increased wasabi cost, high labor cost, etc., and achieve the effect of ensuring particle fineness and adjusting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

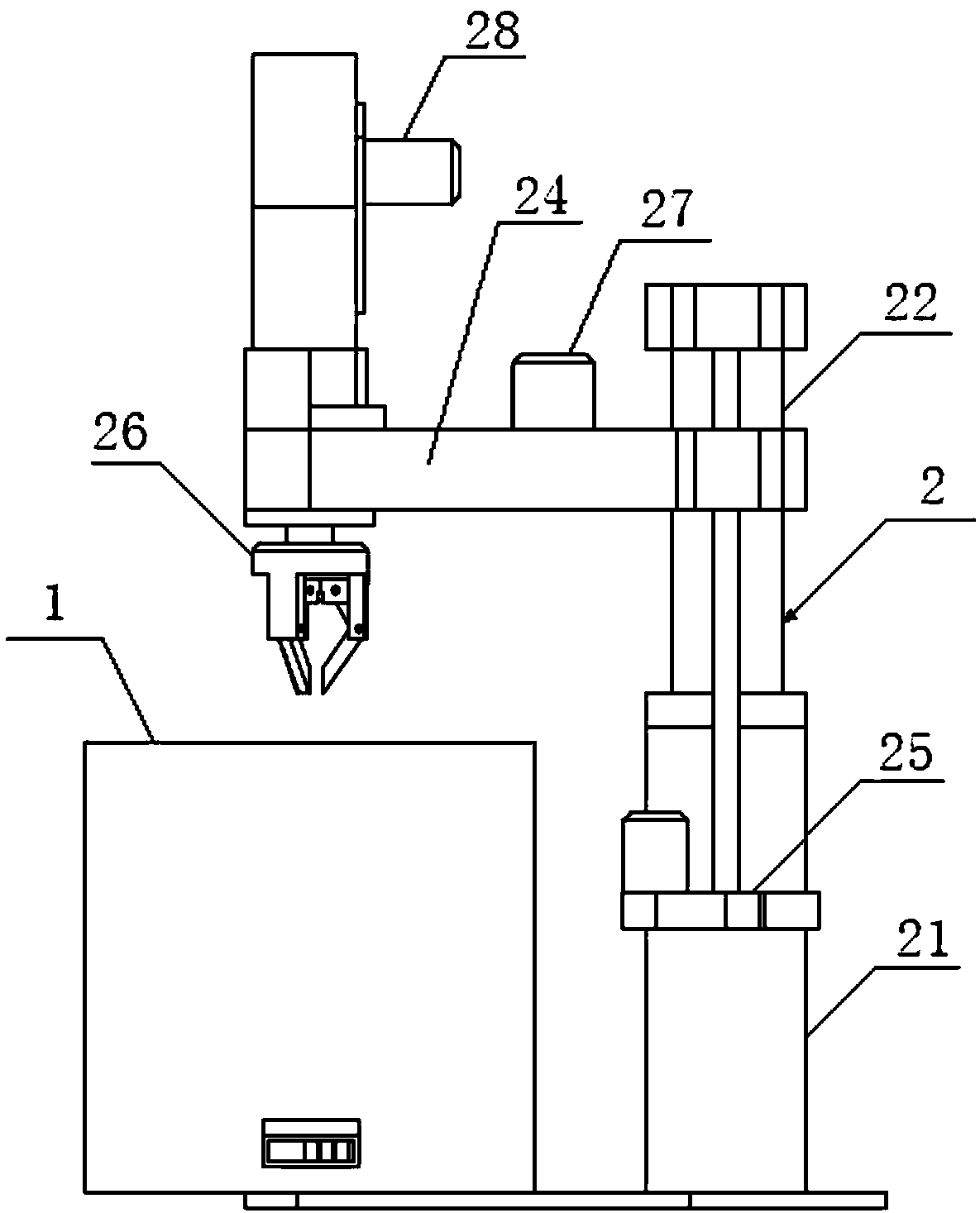

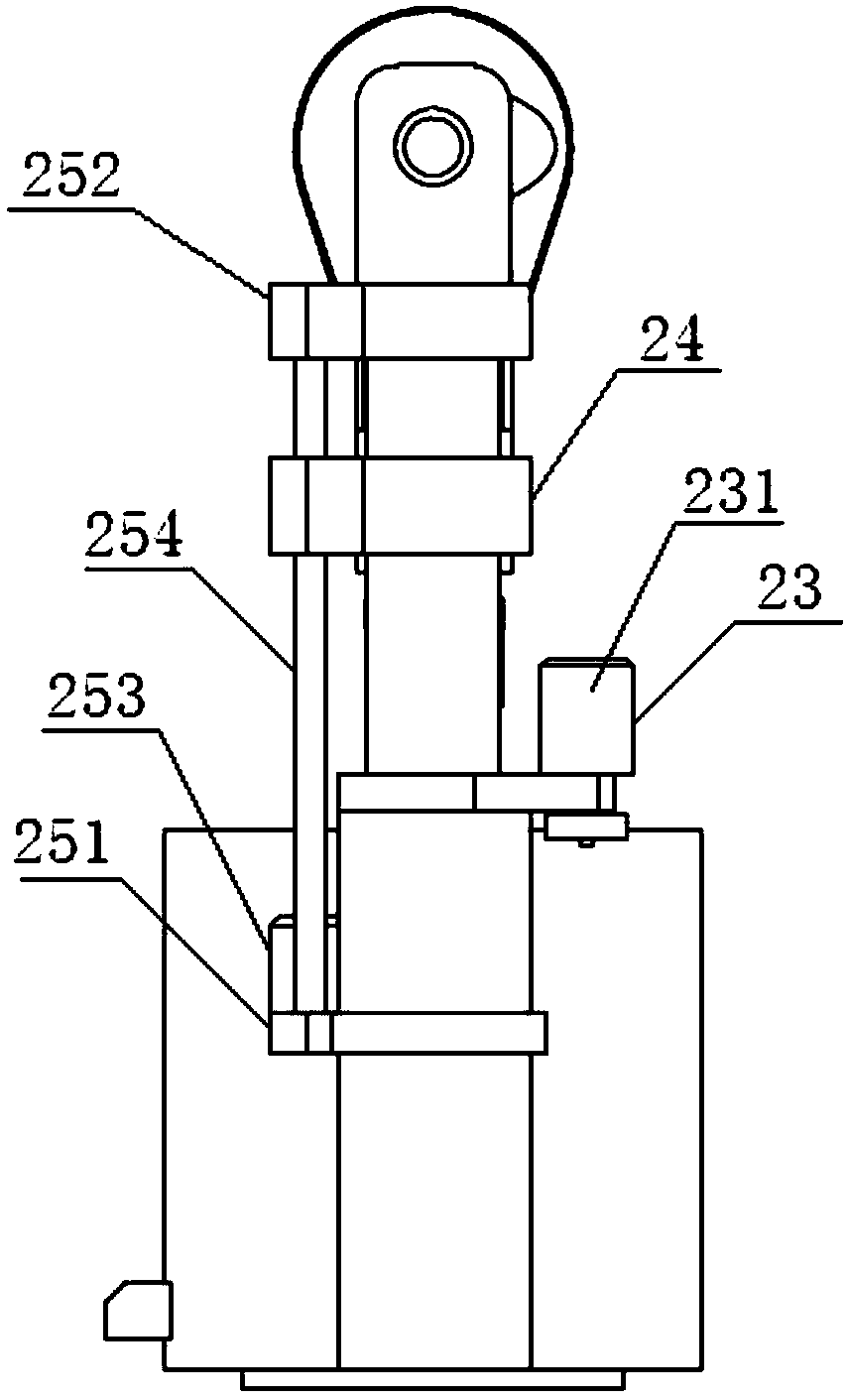

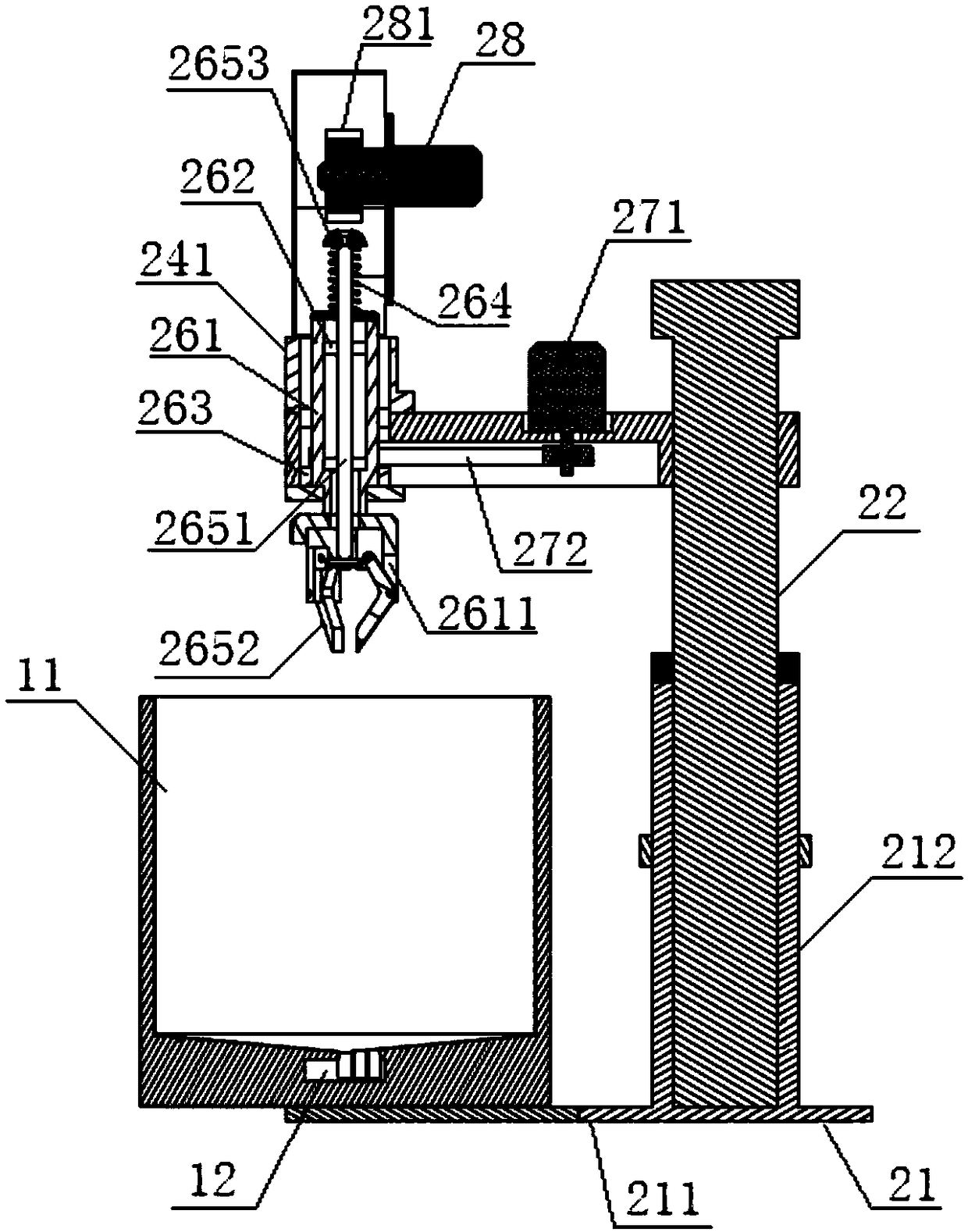

[0018] According to the attached Figure 1 ~ Figure 3 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0019] see Figure 1 ~ Figure 3 , a kind of automatic wasabi grinder that the present invention implements comprises a grinding cylinder 1, a mechanical arm mechanism 2 and a control terminal (not shown in the figure), the control terminal is connected with the mechanical arm mechanism 2 in communication, and the grinding cylinder 1 forms a grinding chamber 11 and a discharge port 12, the bottom surface of the grinding chamber 11 forms grinding lines, the discharge port 12 is formed on the side wall of the grinding cylinder 1 and is located below the grinding chamber 11, the middle part of the bottom surface of the grinding chamber 11 forms a plurality of The channel through which the feed port 12 communicates. The bottom surface of the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com