Bridge bottom surface crack detecting method based on binocular vision

A technology of binocular vision and detection method, applied in the direction of optical testing flaws/defects, etc., can solve the problems of high labor cost, low precision, affecting the accuracy of cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention is described in further detail below in conjunction with accompanying drawing:

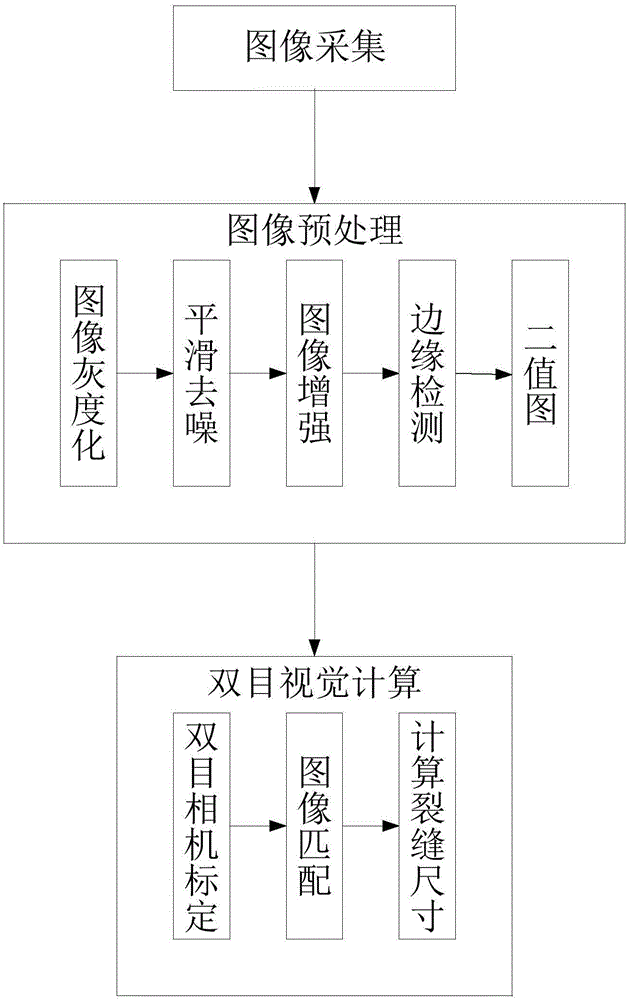

[0067] Such as figure 1 As shown, a binocular vision-based crack detection method on the bottom surface of bridges specifically includes the following steps:

[0068] 4) First, binocular vision dual image acquisition is performed on the bottom of the bridge;

[0069] 5), using the weighted average method to grayscale the double-image crack image obtained in step 1), and then denoising by median filtering, image enhancement is carried out by using the piecewise linear function of the selected threshold, and the Sobel operator is used to perform image enhancement. The crack edge is extracted, and finally the binary image of the crack image is obtained;

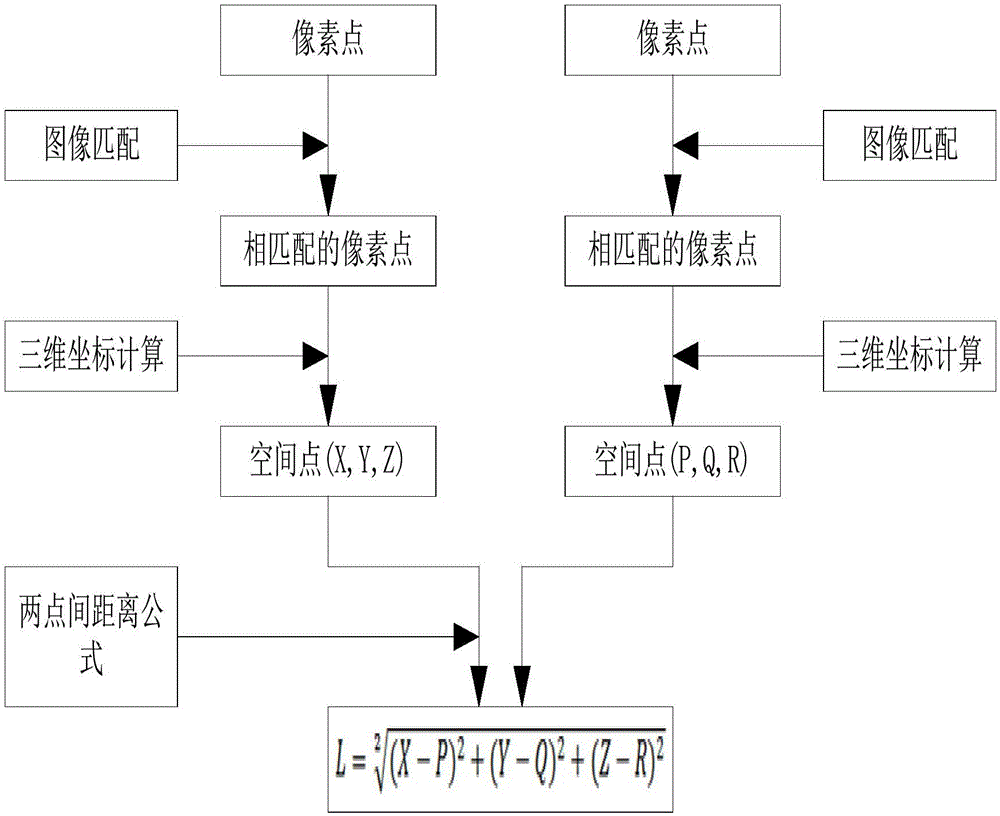

[0070] 6), the dual image collected in step 1) is calibrated by Zhang Zhengyou’s calibration method, and then the binary image obtained in step 2) is matched with the binary image of the obtained crack image using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com