Air-air heat exchange device for defogging and water condensing of cooling tower

A technology of heat exchange device and air-air heat exchanger, which is applied in the directions of water shower cooler, heat exchanger type, direct contact heat exchanger, etc. Problems such as low condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific examples, which are explanations of the present invention rather than limitations.

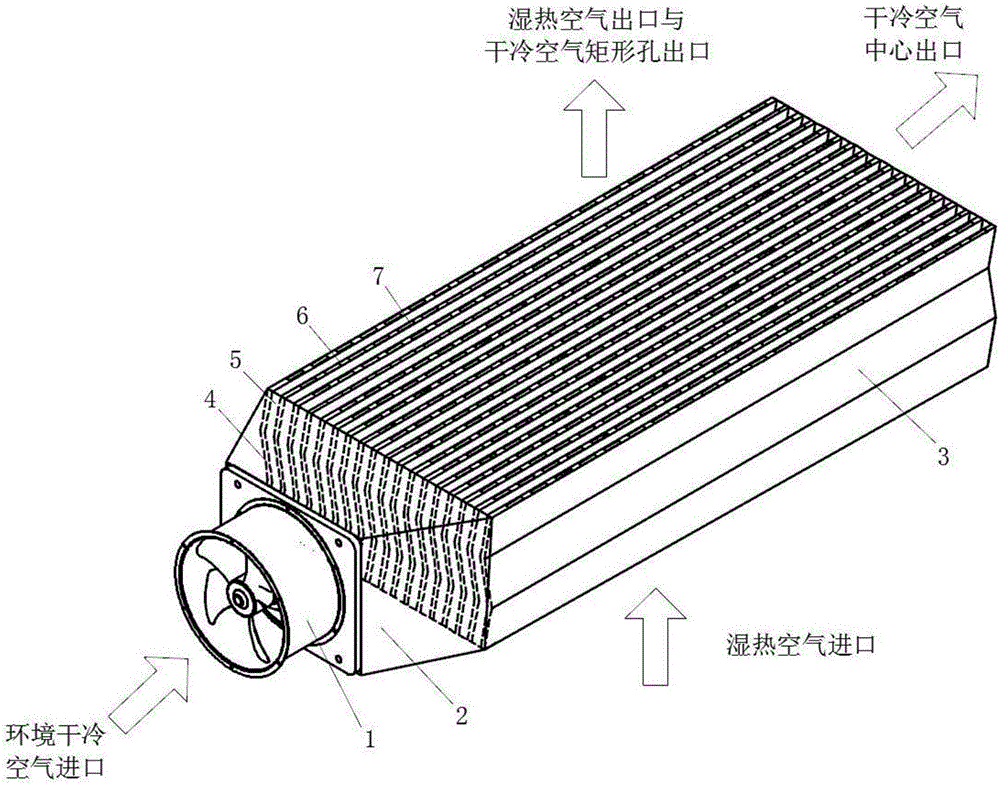

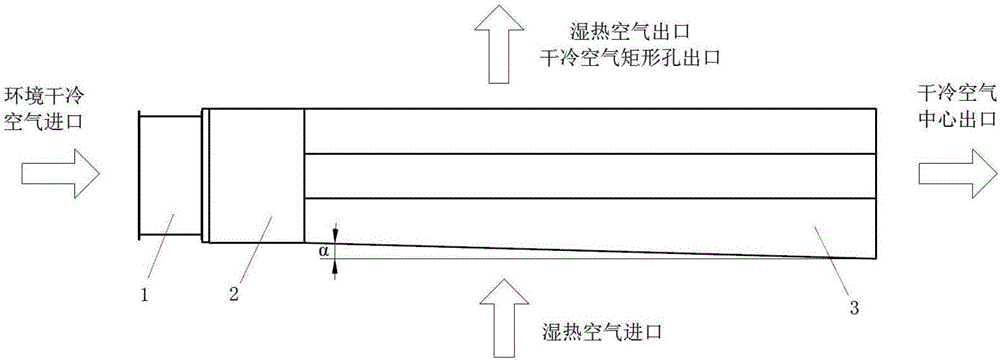

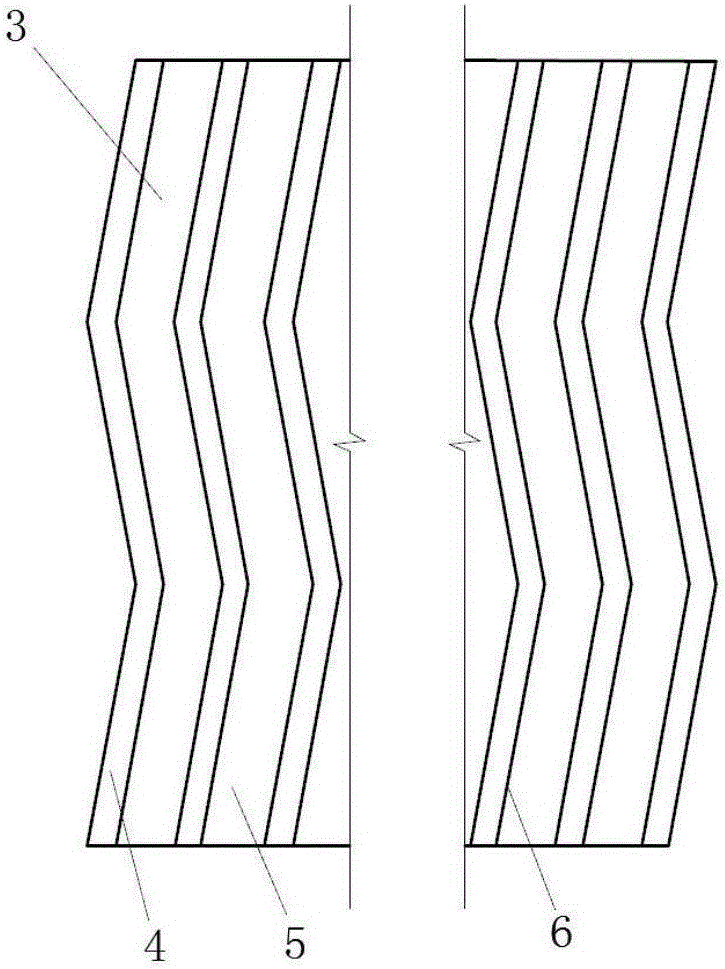

[0027] Such as figure 1 As shown, the device of the present invention is arranged with an axial flow fan 1 , an expanding channel 2 and an air-air heat exchanger 3 in sequence along the flow direction of dry and cold air. Among them, the air-air heat exchanger 3 is composed of a dry and cold air flow channel 4 and a humid and hot air flow channel 5. The two flow channels are combined by heat exchange plates 6 at intervals. The upper part of the dry and cold air flow channel 4 is provided with a rectangular hole 7. . When the heat exchange plates 6 are arranged at intervals, an interlayer space with openings on four sides is formed, such as figure 2 As shown, the interlayer space seals two opposite openings in the horizontal direction to form dry and cold air passages 4, and seals the two oppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com