LNG marine fuel tank system with active upward liquid discharging capacity

A technology for LNG ships and fuel tanks, which is applied to equipment discharged from pressure vessels, pressure vessels, and ship construction details. Effects of operation, reduction of manufacturing and maintenance costs, reduction of manufacturing cost and manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

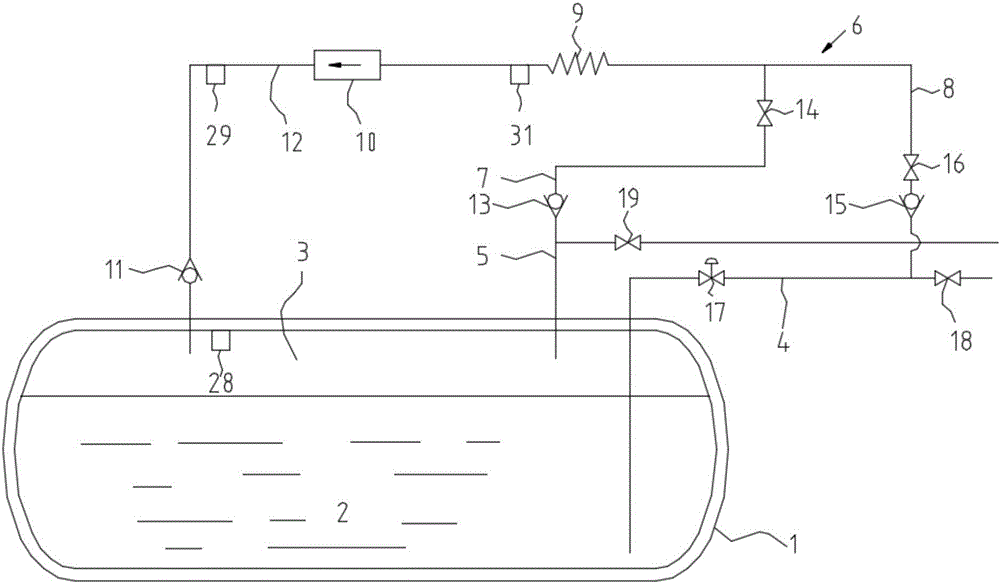

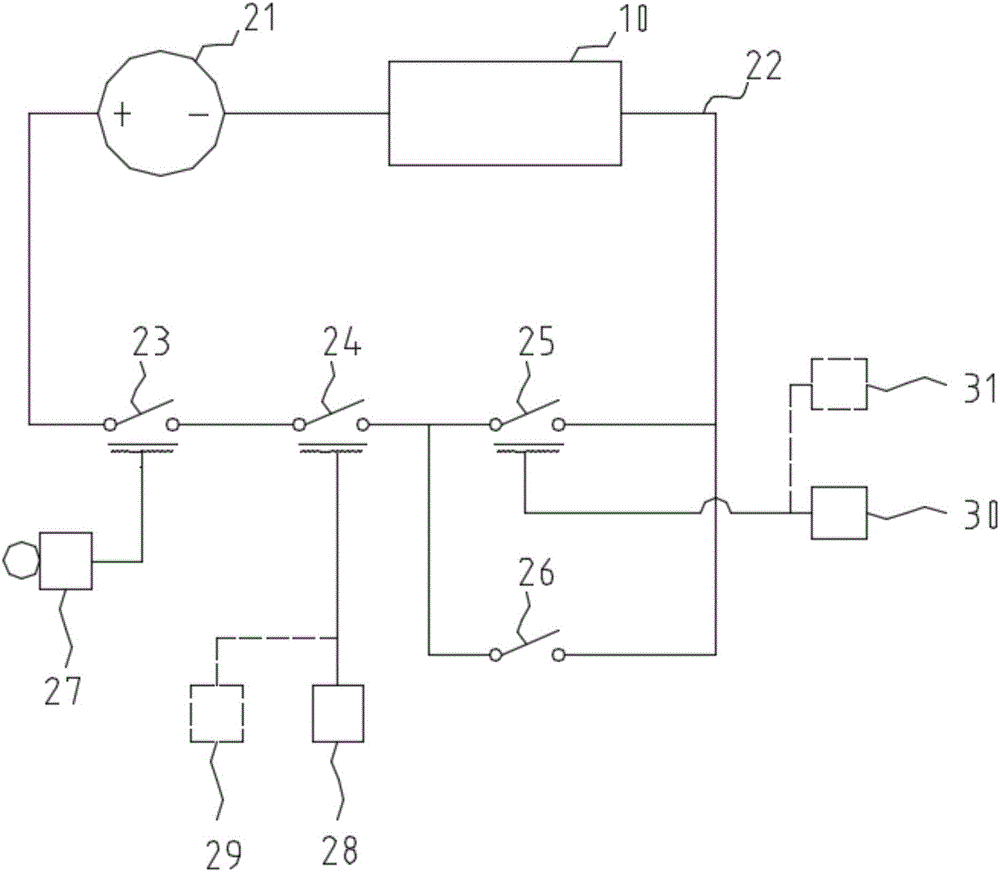

[0014] see Figure 1-2 , a LNG marine fuel tank system with the ability to actively discharge liquid, comprising an electric control box 27, a cryogenic tank body 1, a cryogenic liquid 2, a liquid phase pipeline 4, a gas phase pipeline 5 and a manifold 6, the The cryogenic liquid 2 is located in the inside of the cryogenic tank 1 and the upper end of the cryogenic tank 1 is provided with a first sensor 28, and the upper end of the cryogenic tank 1 is provided with a gas phase space 3, and the first sensor 28 is located in the gas phase space 3 Among them, the liquid phase pipeline 4 communicates with the bottom of the cryogenic tank 1, the liquid phase pipeline 4 is provided with an emergency cut-off valve 17 and a second shut-off valve 18, one end of the gas phase pipeline 5 is connected with the gas phase space 3 and the gas phase The pipeline 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com