Novel drill pipe assembling device

A technology for assembling devices and drill pipes, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of manual operation required for disassembly, affect work efficiency, and cannot realize automatic work, so as to reduce manual operation and labor costs, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

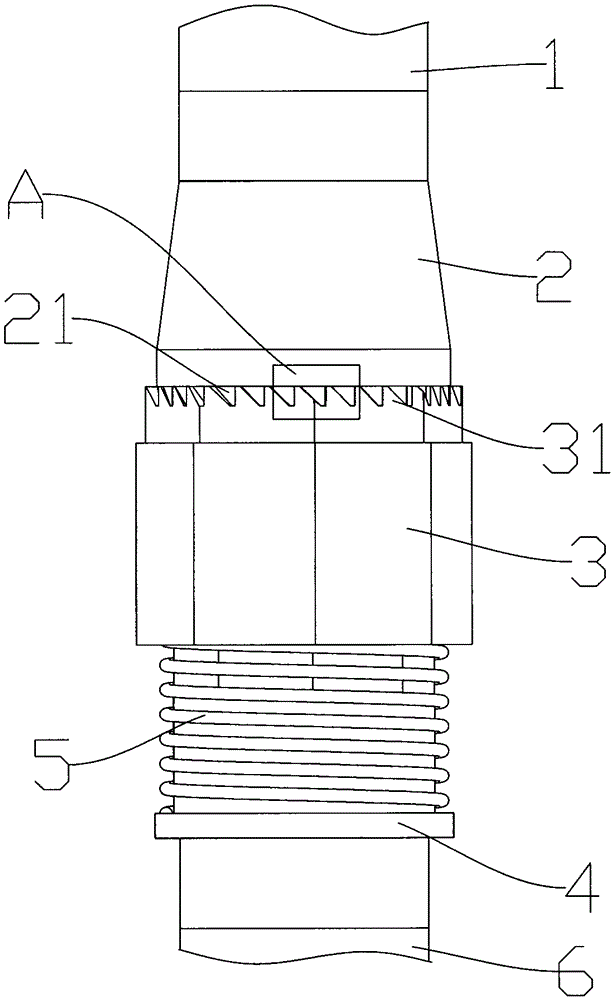

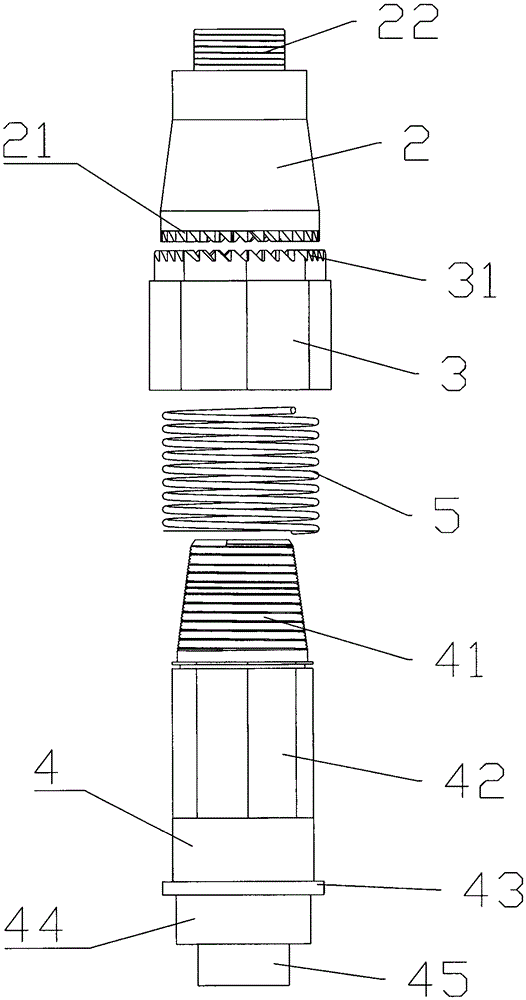

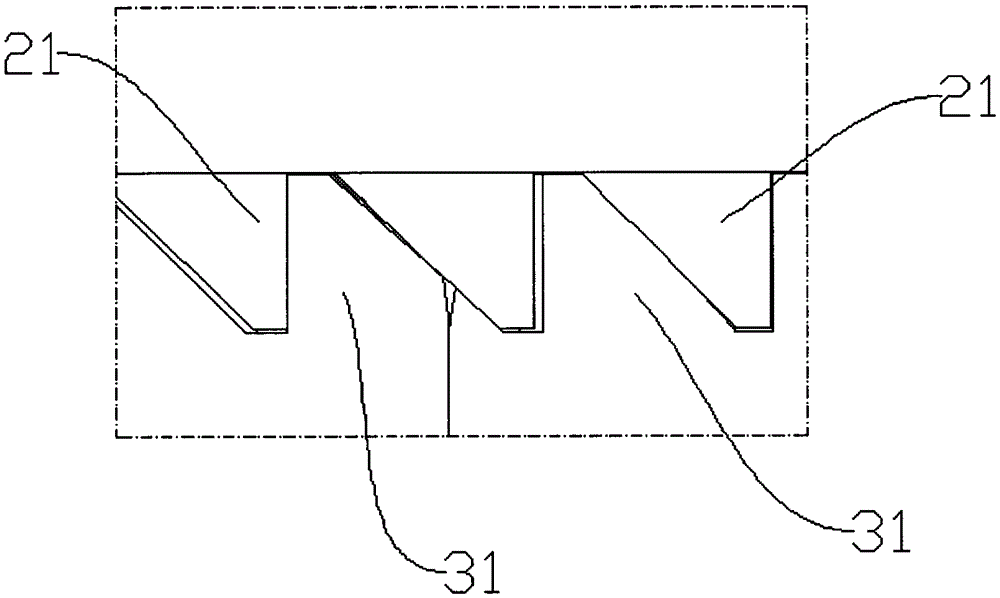

[0026] Such as figure 1 The shown novel drill pipe assembly device of the present invention includes an upper joint 2 and a lower joint 4 connected with an upper drill pipe 1 and a lower drill pipe 6 respectively, and the upper drill pipe 1 is connected with the upper joint 2 and the lower drill pipe 1. The rod 6 and the lower drill bit can be connected in various detachable ways, such as threads, screws, clamping, etc. The upper joint 2 and the lower joint 4 can be rotatably tightened or loosened, and there is a screwable joint between them. threaded connection, and the upper joint 2 and the lower joint 4 are provided with a through channel, the channel is used for pouring mortar, and the lower joint 4 is also fixed with a sliding sleeve 3 in the circumferential direction, and the upper end of the sliding sleeve 3 can be Collision with the lower joint 4 prevents it from rotating in the axial direction. In a specific embodiment, a limit block can be set on the sliding sleeve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com