Integral construction method for constructional column and main body structure

A technology of main structure and construction method, applied in the direction of building structure, columns, piers, etc., can solve the problems of low construction efficiency and high technical requirements of workers, and achieve the effect of improving construction efficiency, improving construction efficiency, and connecting densely without cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Such as Figure 1-5 As shown, a construction method of a structural column and a main body structure in the present invention comprises the steps of:

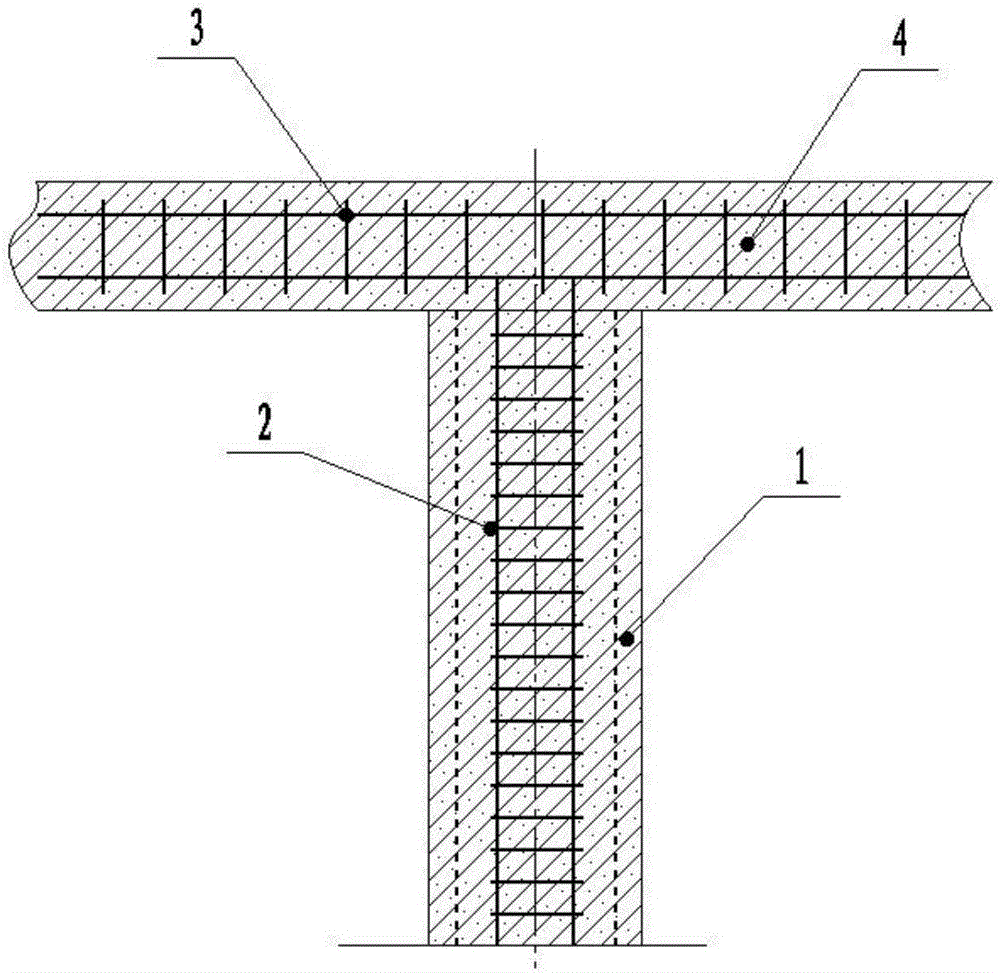

[0033] Step 1) (eg figure 1 As shown) pre-embed the structural column overlap steel bars at the predetermined position of pouring structural column 1;

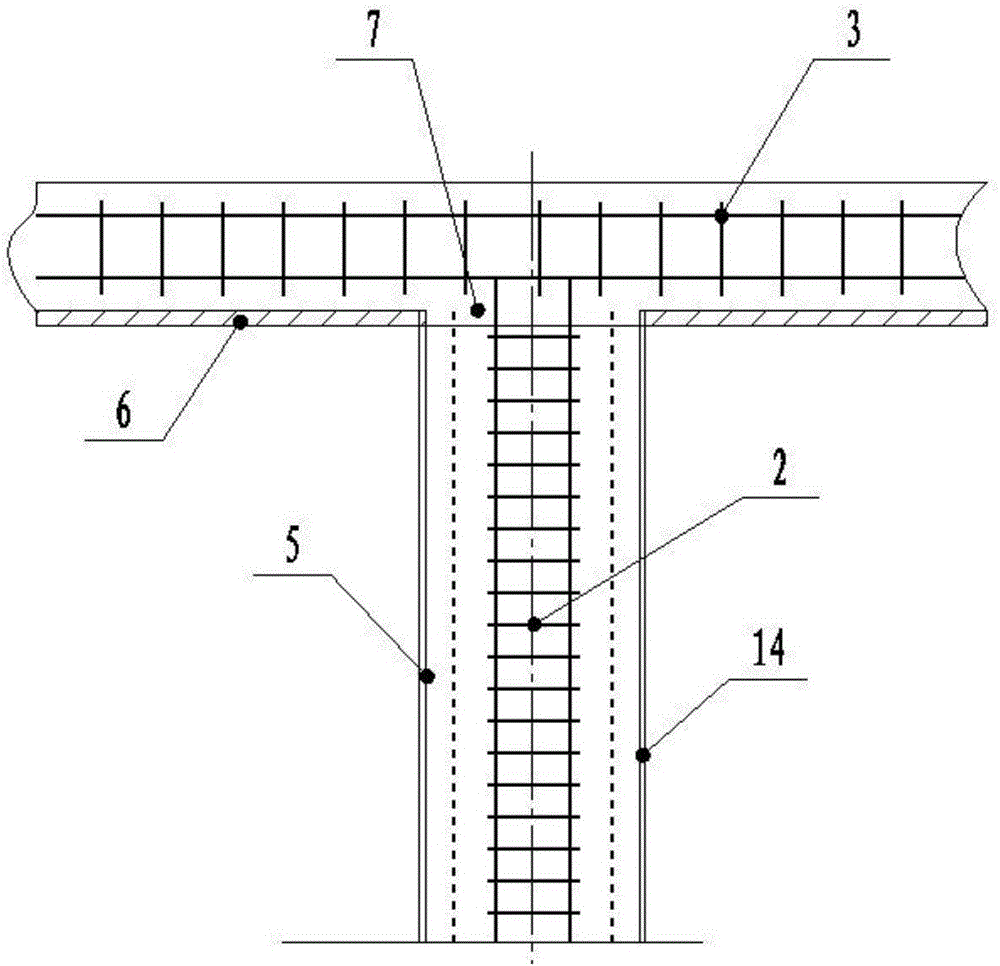

[0034] Step 2) Bind the lower end of the structural column reinforcement cage 2 with the pre-embedded overlapping reinforcement, and bind the upper end with the main structural reinforcement cage 3;

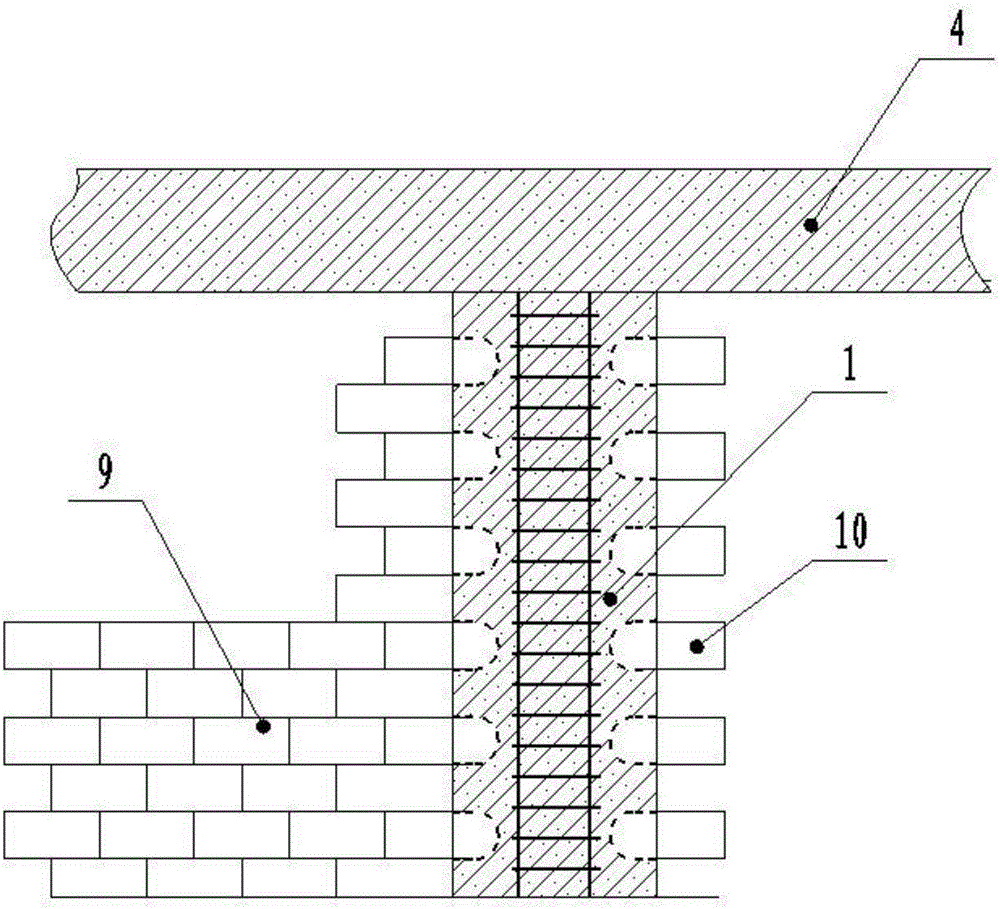

[0035] Step 3) (eg figure 2 As shown) build the construction column pouring formwork 5 of the construction column 1, build the main structure formwork pouring formwork 6 of the main structure 4, and set a construction column pouring through hole 7 at the bottom of the main structure formwork 6, the two sides of the construction column 1 The formwork is a concave structure formwork 14; improve the concave structure formwork 14 so that after the construction column 1 is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com