A kind of brewing method of liquor layered steaming material

A technology of liquor and steaming materials, which is applied in the field of liquor processing, can solve problems such as inconsistent steaming degree and affect the yield and fermentation quality of liquor, and achieve the effect of increasing steam permeability, increasing yield and fermentation quality, and increasing the content of aromatic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

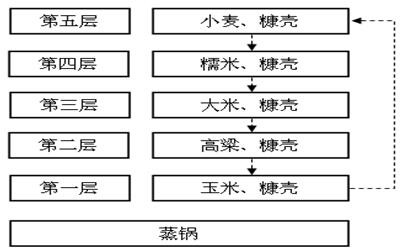

[0017] Weigh 300kg of sorghum, 180kg of rice, 150kg of glutinous rice, 120kg of wheat, 50kg of corn, 10kg of chaff, and 20kg of distiller's yeast. The corn and distiller's koji are crushed, the degree of crushing of each corn is 4-6 petals, and the distiller's koji is crushed to powder without particles; the sorghum, rice, glutinous rice, wheat, corn and bran husks are mixed evenly, and the ratio of bran husks is 1 %quantity. After mixing, place 5 layers of steamers on the steamer, the first layer is corn and bran husk mixture, the second layer is sorghum and bran husk mixture, the third layer is rice and bran husk mixture, and the fourth layer is glutinous rice and bran husk mixture, the fifth layer is wheat and bran husk mixture; after cooking for 10 minutes, move the first layer of corn and bran husk mixture to the fifth layer, and move down the other layers in order to ensure a uniform cooking effect ; When the mixture of wheat and chaff is steamed for 10 minutes in the f...

Embodiment 2

[0019] Weigh 320kg of sorghum, 200kg of rice, 170kg of glutinous rice, 140kg of wheat, 60kg of corn, 22kg of bran hulls, and 25kg of distiller's yeast. The corn and distiller's koji are crushed, and the crushing degree of each corn is 4-6 petals, and the distiller's koji is crushed to a powder without particles; the sorghum, rice, glutinous rice, wheat, corn and bran husks are mixed evenly, and the ratio of bran husks is 2 %quantity. After mixing, place 5 layers of steamers on the steamer, the first layer is corn and bran husk mixture, the second layer is sorghum and bran husk mixture, the third layer is rice and bran husk mixture, and the fourth layer is glutinous rice and bran husk mixture, the fifth layer is wheat and bran husk mixture; after cooking for 15 minutes, move the first layer of corn and bran husk mixture to the fifth layer, and move down the other layers in order to ensure a uniform cooking effect ; When the mixture of wheat and chaff is steamed for 15 minutes ...

Embodiment 3

[0021] Weigh 340kg of sorghum, 210kg of rice, 190kg of glutinous rice, 130kg of wheat, 50kg of corn, 28kg of bran hulls, and 30kg of distiller's yeast. The corn and distiller's koji are crushed, and the crushing degree of each corn is 4-6 petals, and the distiller's koji is crushed to a powder without particles; the sorghum, rice, glutinous rice, wheat, corn and bran husks are mixed evenly, and the ratio of bran husks is 2 %quantity. After mixing, place 5 layers of steamers on the steamer, the first layer is corn and bran husk mixture, the second layer is sorghum and bran husk mixture, the third layer is rice and bran husk mixture, and the fourth layer is glutinous rice and bran husk mixture, the fifth layer is wheat and bran husk mixture; after cooking for 12 minutes, move the first layer of corn and bran husk mixture to the fifth layer, and move down the other layers in order to ensure a uniform cooking effect ; When the mixture of wheat and chaff is steamed for 10 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com