Rubber composition for manufacturing wrapping cloth V-belt compression layer and preparation method of rubber composition

A technology of rubber composition and V-belt, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of shortened service life and reduced flex fatigue resistance, and achieve extended service life and excellent resistance to compression fatigue Performance, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

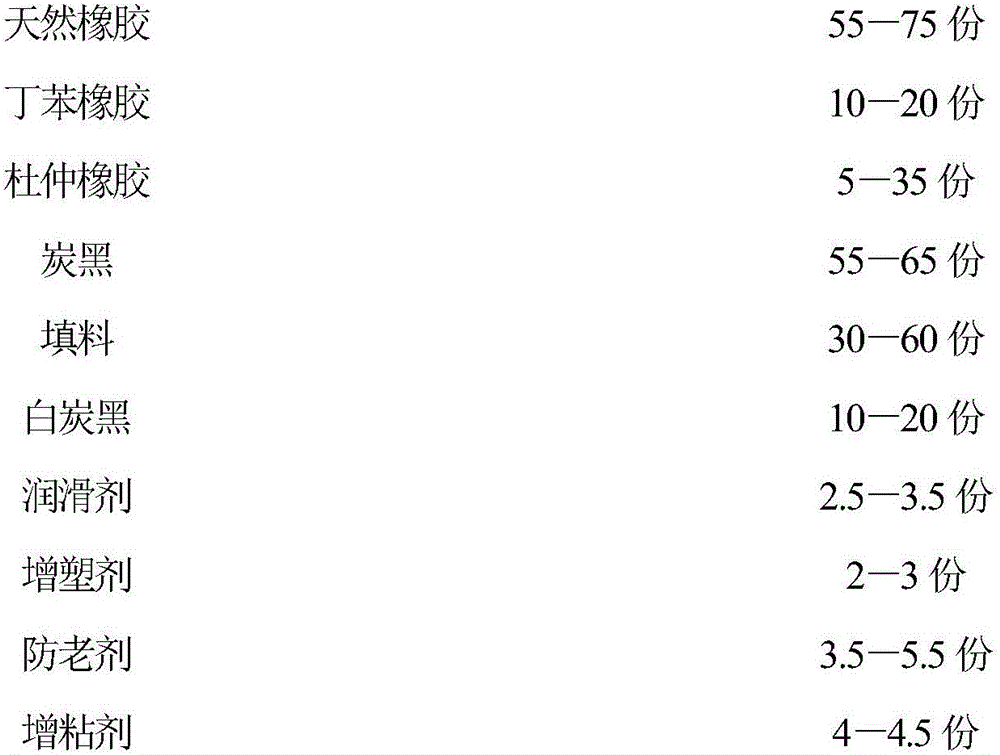

[0036] A kind of rubber composition that is used for making the compression layer of covered cloth V-belt, its raw material component and mass fraction are as follows:

[0037]

[0038] The preparation method step of producing this rubber composition is as follows:

[0039] After pressure mixing natural rubber and styrene-butadiene rubber, add Eucommia rubber for mixing, then add polyethylene glycol PEG-4000, anti-aging agent RD and anti-aging agent 4010NA, coumarone resin, zinc oxide, N-cyclohexyl -2-Benzothiazole sulfenamide and dithiobenzothiazole are mixed, then add pine tar, high wear-resistant carbon black N330 and general carbon black N660, silica hydrate, light calcium carbonate and aluminum silicate The hydrate is mixed, and when the temperature reaches 125-135 ° C, the mixed rubber material is discharged to the open mill, and insoluble sulfur is added to further re-glue and mix for 2-3 minutes, and then the next piece is ready for use.

[0040] The vulcanizate of...

Embodiment 2

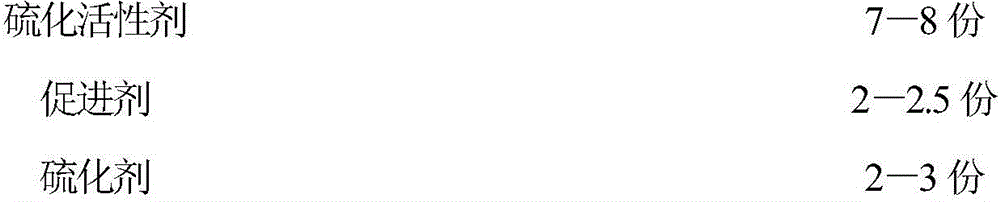

[0043] A kind of rubber composition that is used for making the compression layer of covered cloth V-belt, its raw material component and mass fraction are as follows:

[0044]

[0045]

[0046] The preparation method step of producing this rubber composition is as follows:

[0047] After pressure mixing natural rubber and styrene-butadiene rubber, eucommia rubber was added for mixing, and then polyethylene glycol PEG-4000, anti-aging agent RD, anti-aging agent 4010NA and anti-aging agent 4020, coumarone resin, zinc oxide, Mix N-cyclohexyl-2-benzothiazole sulfenamide and dithiobenzothiazole, then add pine tar, high wear-resistant carbon black N330 and general carbon black N660, silica hydrate, light calcium carbonate Mix with aluminum silicate hydrate, when the temperature reaches 125-135°C, discharge the mixed rubber material to the open mill, add insoluble sulfur, and then return to the glue and mix for 2-3 minutes, and then release the tablet for use.

[0048] The vu...

Embodiment 3

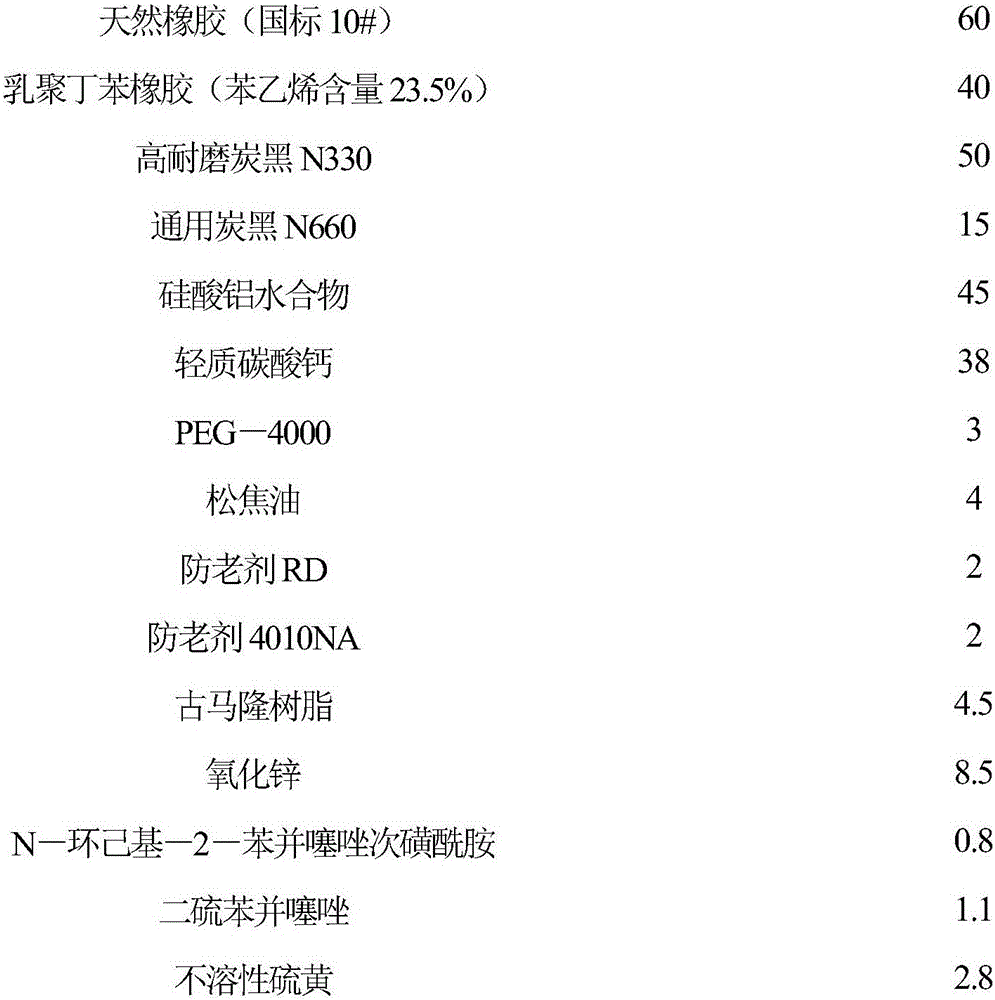

[0051] A kind of rubber composition that is used for making the compression layer of covered cloth V-belt, its raw material component and mass fraction are as follows:

[0052]

[0053]

[0054] The preparation method step of producing this rubber composition is as follows:

[0055] After pressure mixing natural rubber and styrene-butadiene rubber, add Eucommia rubber for mixing, then add polyethylene glycol PEG-4000, anti-aging agent RD and anti-aging agent 4020, coumarone resin, zinc oxide, N-cyclohexyl -2-Benzothiazole sulfenamide and dithiobenzothiazole are mixed, then add pine tar, high wear-resistant carbon black N330 and general carbon black N660, silica hydrate, light calcium carbonate and aluminum silicate The hydrate is mixed, and when the temperature reaches 125-135 ° C, the mixed rubber material is discharged to the open mill, and insoluble sulfur is added to further re-glue and mix for 2-3 minutes, and then the next piece is ready for use.

[0056] The vulc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com