Phosphorene-graphene composite material and preparation method thereof

A graphene composite and composite material technology, which is applied in the preparation of graphene and phosphorus, nanotechnology for materials and surface science, etc. It is difficult to control the quality and other problems, so as to achieve the effect of easy control of product quality, excellent mechanical strength and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

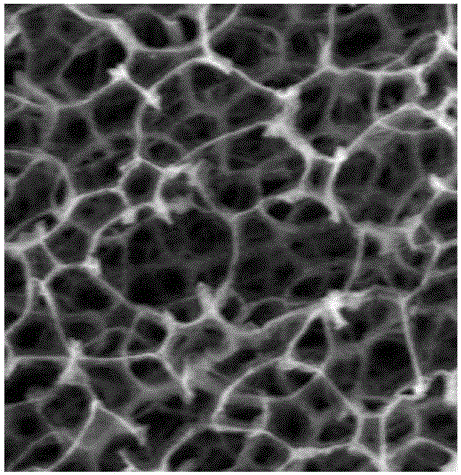

Image

Examples

preparation example Construction

[0024] Specifically, the preparation method of phosphorene-graphene composite material provided by the present invention comprises the following steps:

[0025] Step A, vacuum ball milling phosphorene and graphite oxide, and then adding them into the dispersion liquid for dispersion, so as to obtain a mixed suspension of phosphorene and graphite oxide.

[0026] Specifically, phosphorene and graphite oxide are vacuum ball milled together for 0.1 to 48 hours, and then added to the dispersion liquid for ultrasonic dispersion. The ultrasonic dispersion time is 10 to 240 minutes, thereby obtaining phosphorene and graphite oxide. The concentration of graphite mixed together is a mixed suspension of 0.1 to 100g / L. Wherein, the amount of phosphorene accounts for 10% to 90% of the total amount of phosphorene and graphite oxide, the degree of oxidation of graphite oxide is 10% to 90%, and the dispersion liquid is water, methanol, ethanol, acetone, ether , carbon tetrachloride, N,N-dime...

Embodiment 1

[0038] A kind of phosphorene-graphene composite material, its preparation method comprises the following steps:

[0039]Step a1. Vacuum ball mill 1 g of phosphorene and 9 g of graphite oxide with an oxidation degree of 15%. The time of vacuum ball milling is 0.5 hours, and then add it into a mixed solution of acetone and water for ultrasonic dispersion. The time of ultrasonic dispersion is 60 min. , so as to obtain a mixed suspension of phosphorene and graphite oxide with a concentration of 0.2 g / L.

[0040] Step b1. Soak aluminum foam in the mixed suspension for 20 minutes, and heat and vacuum-dry the mixed suspension at a heating temperature of 45° C. to make all the acetone and water in the mixed suspension Volatilize, then place in a tube furnace with nitrogen and hydrogen mixed gas (hydrogen gas fraction in this mixed gas is 2%), heat to 600 ° C, and keep warm for 3 hours, thus obtain the phosphorene-graphene composite material precursor .

[0041] Step c1, immersing th...

Embodiment 2

[0044] A kind of phosphorene-graphene composite material, its preparation method comprises the following steps:

[0045] Step a2, carry out vacuum ball milling together with 1.5g phosphorene and 7g graphite oxide with 20% oxidation degree, the time of vacuum ball milling is 3 hours, then join in the mixed solution of acetonitrile and water and carry out ultrasonic dispersion, the time of ultrasonic dispersion is 90min, thereby obtaining the mixed suspension of phosphorene and graphite oxide with a concentration of 3g / L.

[0046] Step b2, soak nickel foam in the mixed suspension for 60 minutes, and heat and vacuum-dry the mixed suspension at a heating temperature of 80°C to make all the acetonitrile and water in the mixed suspension Volatilize, then place in a tube furnace with a mixed gas of nitrogen and hydrogen (the hydrogen gas fraction in this mixed gas is 5%), heat to 700 ° C, and keep warm for 5 hours, thereby obtaining the precursor of phosphorene-graphene composite mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com