Track system of vacuum high-speed train

A technology for high-speed trains and vacuum pipes, applied in the field of rail systems, can solve the problems of complex structural design, expensive construction, and difficulty in putting into operation, and achieve the effects of improving safety and reliability and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

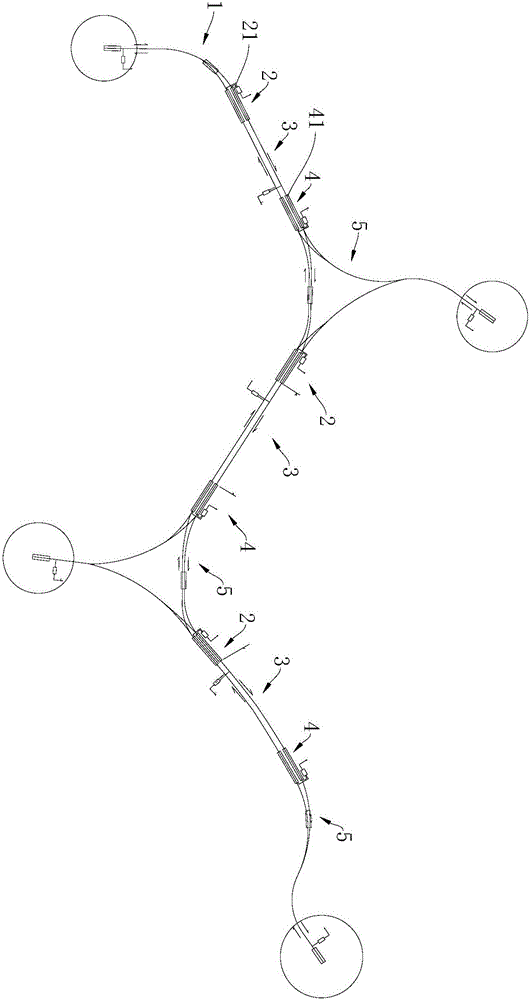

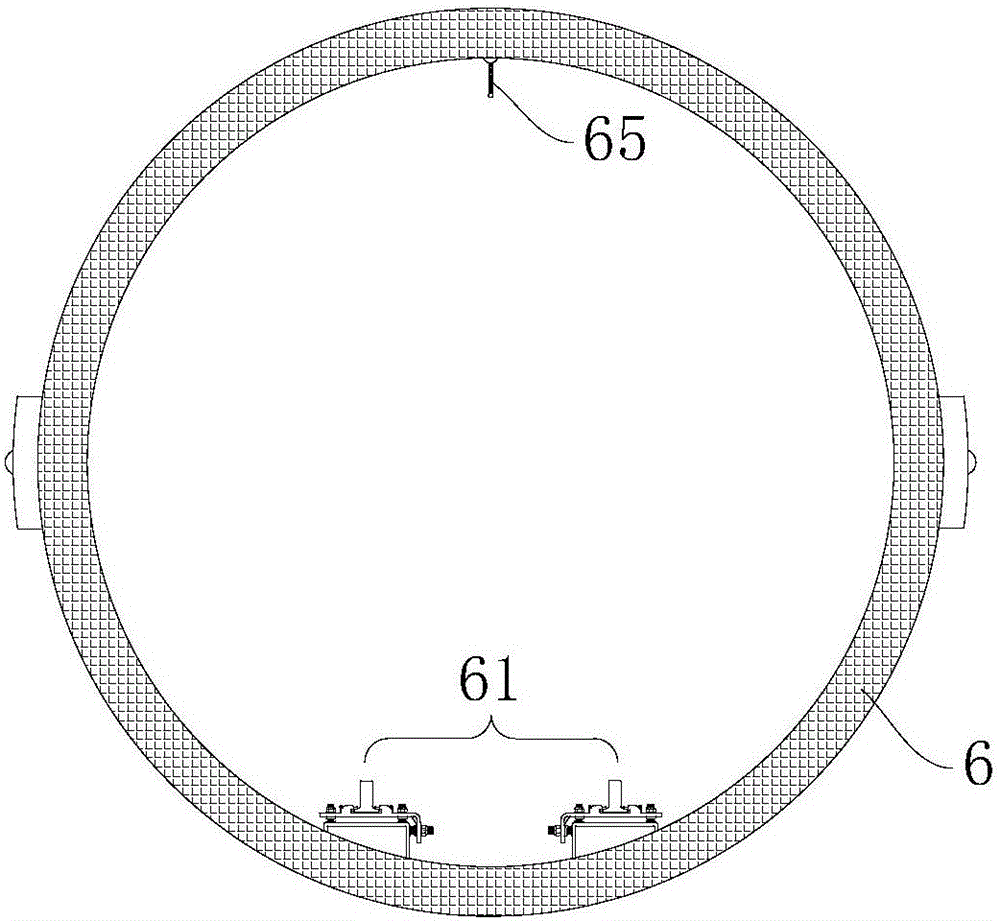

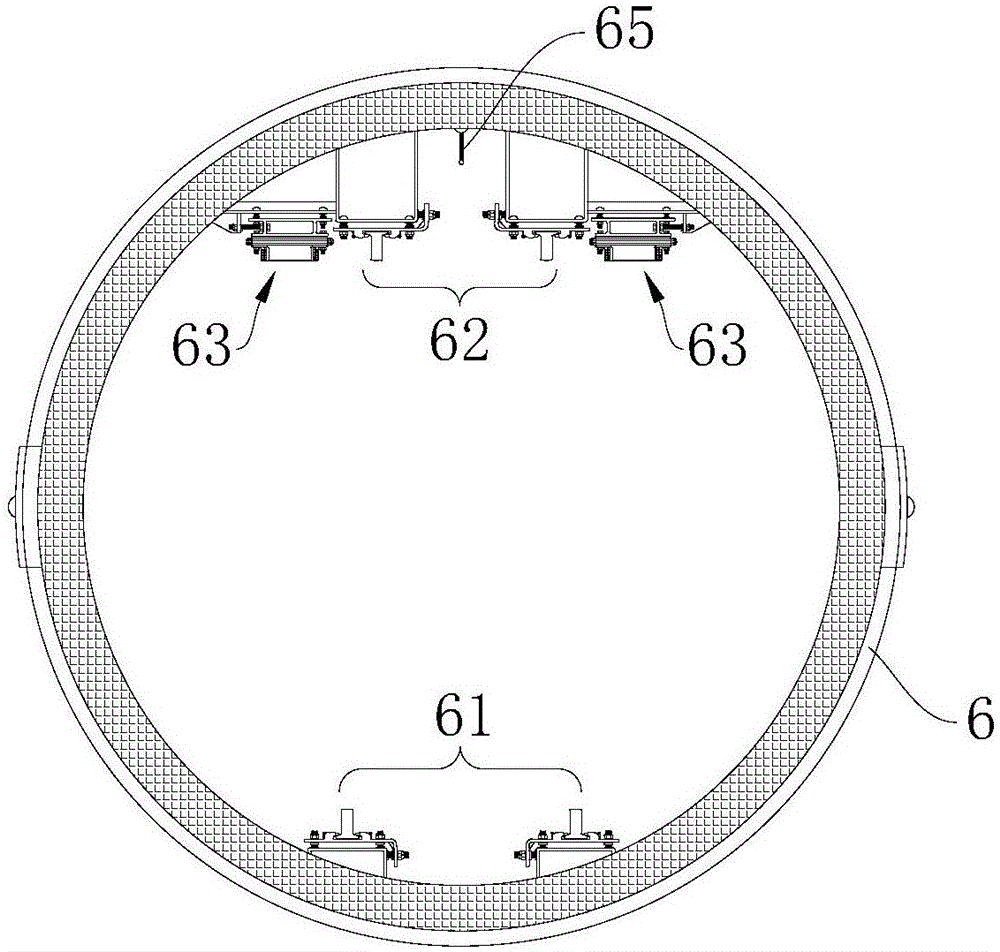

[0026] combine Figure 1 to Figure 4 As shown, the present embodiment provides a track system for a vacuum high-speed train, including a first wheel-rail running section 1 for running a wheel-rail when the high-speed train leaves the station, and connecting with the first wheel-rail running section 1 The connected magnetic levitation acceleration section 2, the magnetic levitation sliding section 3 connected through the magnetic levitation acceleration section 2, the magnetic levitation deceleration energy recovery section 4 connected through the magnetic levitation gliding section 3, and the magnetic levitation deceleration energy recovery section 4 connected Connect to the second wheel-rail running section 5 for high-speed trains entering the station.

[0027] Specifically, in this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com