Multifunctional paint spraying device

A multi-functional, paint room technology, applied in spray devices, devices for applying liquid to surfaces, pre-treatment surfaces, etc., can solve the problems of difficult cleaning of paint, affecting product quality, uneven painting, etc., and achieve overall structural design. Ingenious, easy to maintain, good for setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

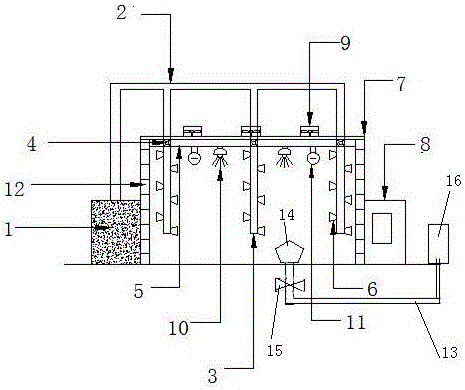

[0015] Example 1: see Figure 1-Figure 2 , A multifunctional paint spraying device, the multifunctional paint spraying device includes a paint spraying component, a heating and exhausting component, a control component flushing component and a shed body component; the paint spraying component is partially located in the shed body component, and the rest is located in the shed body component Outside; the heating exhaust assembly is located inside the shed assembly; the control assembly includes a temperature sensor and a paint room control room, the temperature sensor is arranged in the shed assembly, the paint room control room is arranged outside the shed assembly , The shed assembly includes a heat insulation shed 12 and a heat insulation awning 7, the heat insulation awning is arranged on the heat insulation shed 12, the washing assembly includes a washing pipe 13 and a washing pipe arranged at one end of the washing pipe The spray head 14 and the valve 15 arranged on the fl...

Embodiment 2

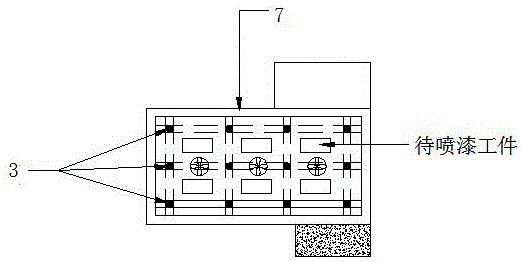

[0016] Example 2: see Figure 1-Figure 2 As an improvement of the present invention, the paint spraying component includes a paint mixing room 1, a paint delivery pipe 2, a movable pipe string 3, a pulley 4, a pulley running track 5 and a paint mist nozzle 6, and the paint mixing room passes The paint delivery pipeline is connected to the top of the movable pipe string; the movable pipe string is fixed at the lower end of the pulley, the pulley is arranged on the pulley running track, the pulley running track is fixed under the heat insulation roof, and the paint The mist nozzle is arranged on the side wall of the movable pipe string. The advantage of this design lies in the precise positioning of the required painting work piece in the house by controlling the movable pipe string. According to the size of the workpiece to be painted, the distribution position of the movable pipe string is changed, and the paint spray nozzle is accurately aligned with the required painting sur...

Embodiment 3

[0017] Example 3: See Figure 1-Figure 2 As an improvement of the present invention, the heating exhaust assembly includes an exhaust fan 9 and an infrared grill lamp 10; the exhaust fan 9 is installed on the heat insulation roof 7; the infrared grill lamp is suspended under the insulation roof. The use of infrared baking lamps as the heating source not only heats up quickly, but also has low energy consumption, which further makes this product meet the national energy saving and emission reduction requirements. The computer in the paint room control room can not only adjust the room temperature through a temperature sensor, but also control the color and concentration of the paint mist produced in the paint mixing room. The computer can control the temperature required in the painting operation, which can make the indoor temperature constant, which is more conducive to the solidification of the paint surface. The computer paint mixing is not only accurate in coloring, but als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com