Permanent magnet motor block stator assembly tooling

A permanent magnet motor and stator assembly technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., to achieve the effects of shortening the production cycle, reducing insulation damage, and improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

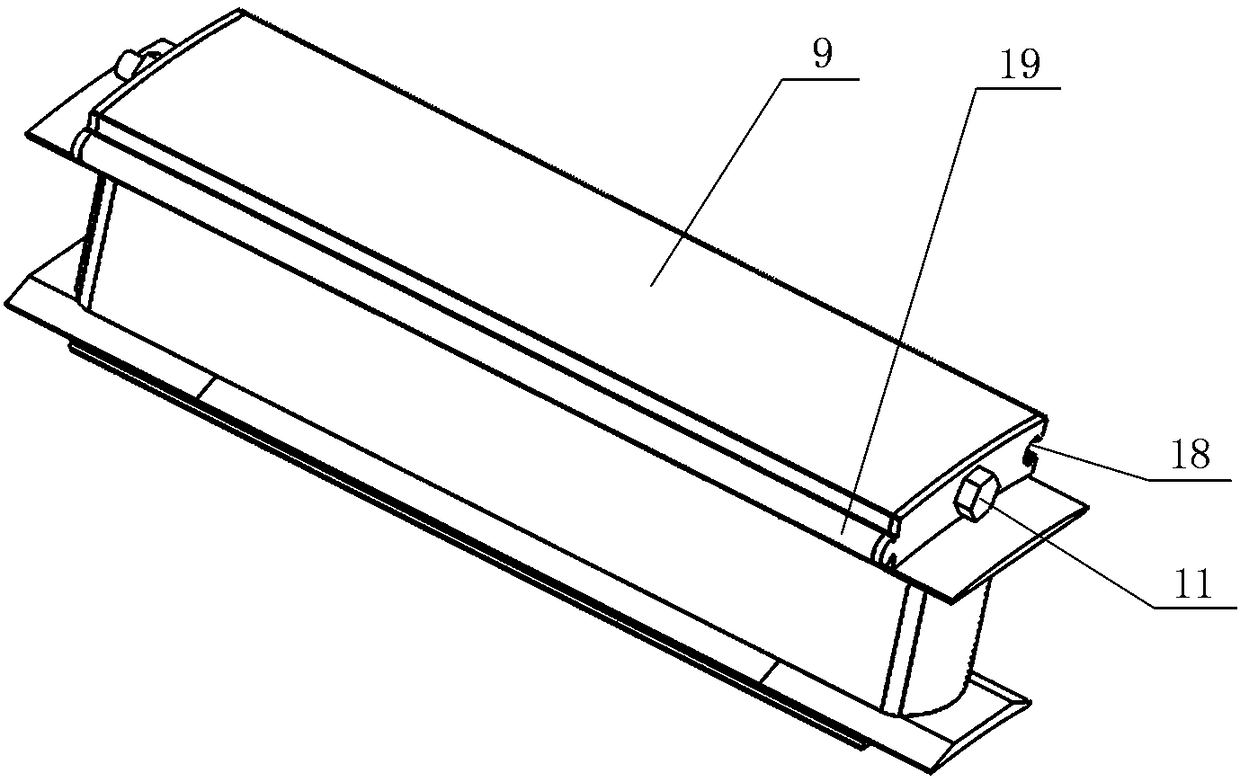

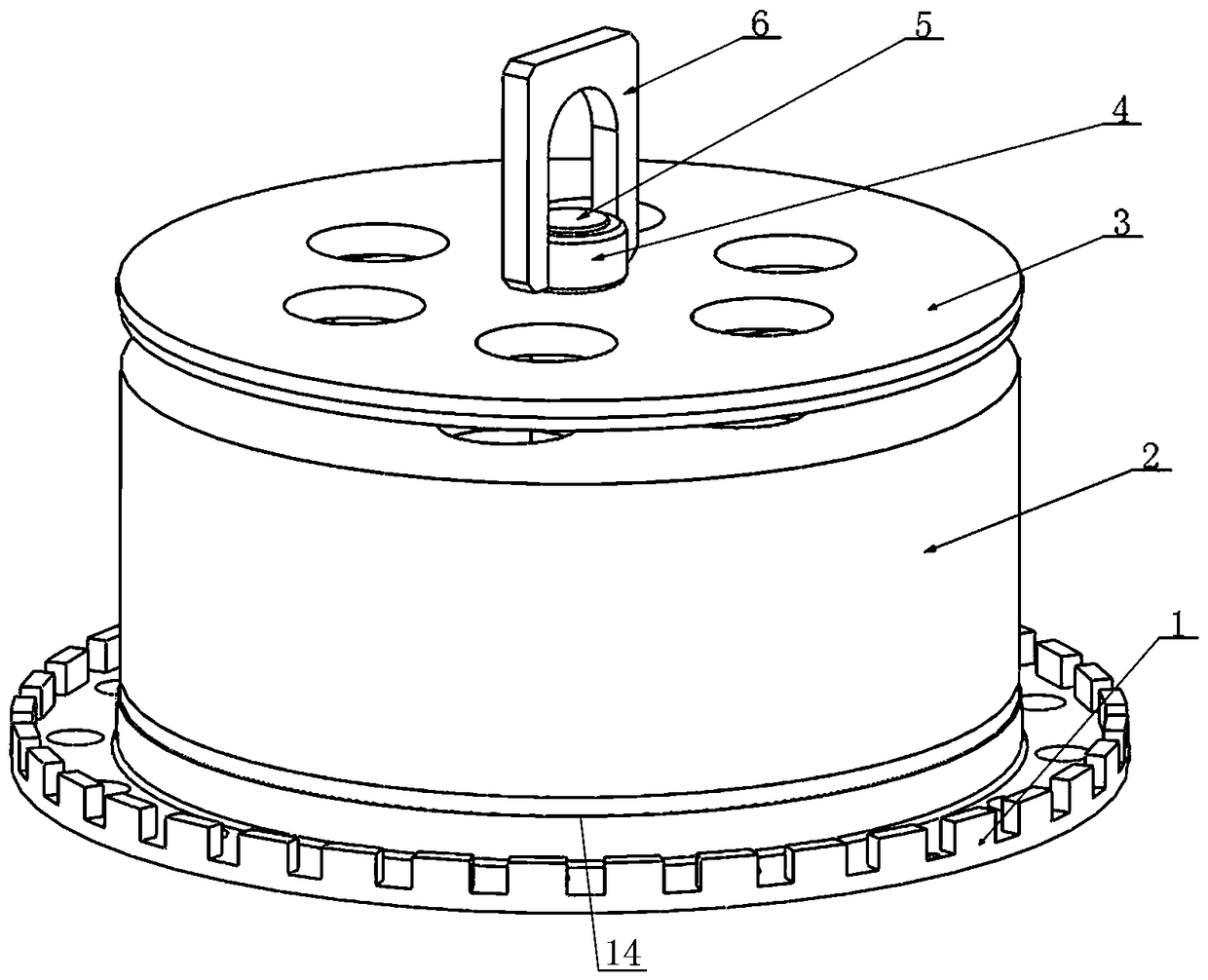

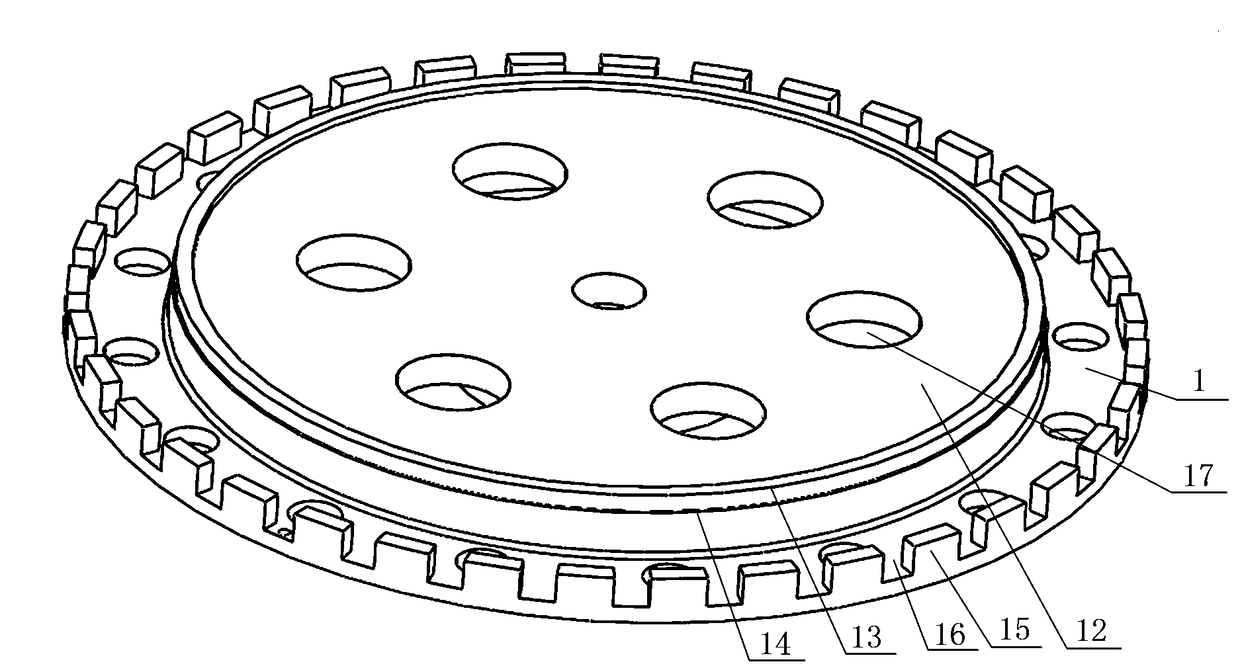

[0024] A piece stator assembly tool for a permanent magnet motor, consisting of a piece tool base 1, a piece tool mandrel 2, a pressure plate 3, an upper limit nut 4 (the lower limit nut is located under the pressure plate), a pressure rod bolt 5, and lifting lugs 6 and other components, the specific connection relationship is as follows figure 2 , 3 As shown, the base 1 is provided with a central circular boss 12, and the outer circumference of the central circular boss 12 is provided with a circle of mandrel positioning notch 13 (cooperating with the notch on the lower end surface of mandrel 2) and a circle of stator positioning notch 14 (The spigot is the installation limit of the stator block), the outer circumference of the base 1 is provided with the same number of bosses 15 and grooves 16 as the number of slots in the stator 9 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com