Method and device for decoking high-temperature heating surface of supercritical tower boiler by using frequency-adjustable high-sound-intensity sound waves

A tower furnace and supercritical technology, which is applied in the direction of combustion method, solid residue removal, lighting and heating equipment, etc., can solve the problem of coking on the high-temperature heating surface of the boiler, achieve energy saving, broad application prospects, and simple implementation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for decoking the high-temperature heating surface of a supercritical tower furnace with frequency-adjustable high-intensity sound waves. Coke and ash removal, the specific implementation method is to install the sound conduit of the frequency-adjustable high-sonic-intensity sound wave generator at the position of the high-temperature superheater and high-temperature reheater inside the tower furnace for decoking and ash removal. The frequency-adjustable high-intensity sound source provides defocusing sound waves of a specific frequency. The defocusing sound waves are transmitted into the high-temperature heating surface through the sound conduit, and the sound waves diffuse and propagate inside the high-temperature heating surface. When the coke is gray, it will drive the coke to vibrate, thereby destroying the adhesion between the coke and the metal surface of the heating surface. Once the adhesion between the coke and the metal surface...

Embodiment 2

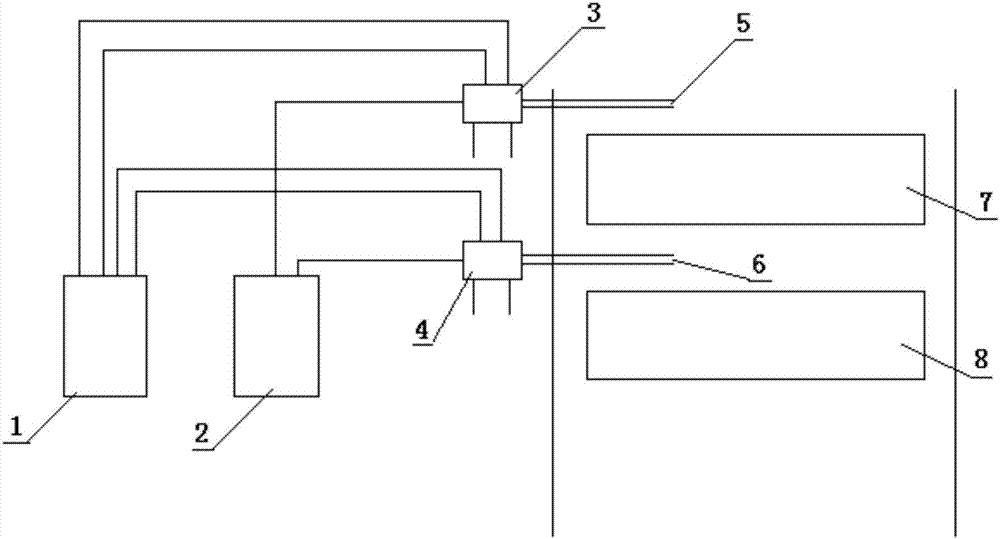

[0033] This embodiment provides a device for frequency-adjustable high-intensity sound wave decoking on the high-temperature heating surface of a supercritical tower furnace, which includes a frequency-adjustable high-intensity sound source arranged outside the high-temperature heating surface of a supercritical tower furnace, and a high-intensity sound source arranged in a supercritical tower Acoustic ducts at the position of the high temperature superheater and high temperature reheater inside the furnace.

[0034] Specific as figure 1 As shown, the high-temperature heating surface of the supercritical tower furnace provided by this embodiment can be used for frequency-adjustable high-intensity sound wave decoking. Sound source 3, the second adjustable frequency high-intensity sound source 4, the first sound conduit 5 and the second sound conduit 6, wherein the first sound conduit 5 is arranged inside the supercritical tower furnace towards the high-temperature reheater 7, a...

Embodiment 3

[0038]Taking a 600MW tower furnace unit in a power plant as an example, the specific implementation method is as follows:

[0039] On the high-temperature heating surface of the tower furnace: the high-temperature superheater and the high-temperature reheater are equipped with acoustic wave decoking equipment.

[0040] Among them, two sets of frequency-adjustable high-intensity sound wave decoking equipment are installed symmetrically on both sides of the high-temperature superheater. During normal operation, the frequency-adjustable high-sound intensity sound wave decoking equipment provides sound waves with a frequency of 20-8000 Hz, and the sound waves pass through a specific sound guide. Introduce high-intensity sound waves into the flue where the high-temperature superheater is located, remove the coke on the surface of the high-temperature superheater, increase the heat transfer efficiency of the high-temperature superheater, and ensure the stable operation of the unit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com