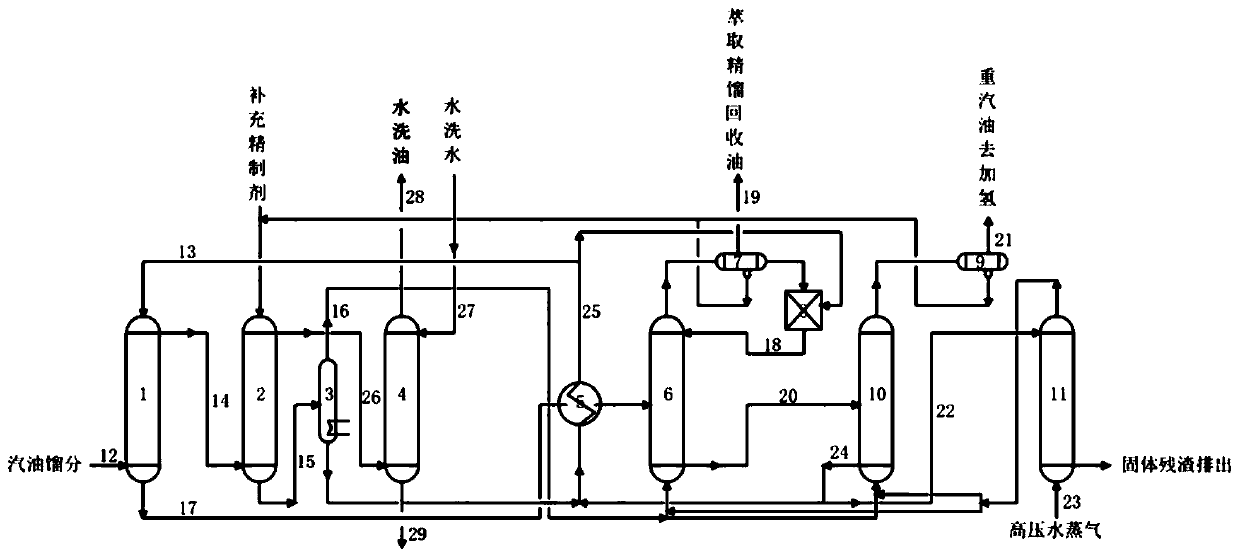

A kind of method for extraction-extractive rectification to reduce the sulfur content of regenerated and recovered oil

A technology of extractive distillation and recovery of oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, and only multi-stage serial refining process treatment, etc. Solve problems such as high sulfur content, achieve the effect of improving desulfurization capacity, reducing sulfur content, and reducing agent-oil ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]The extractive distillation recovery oil obtained from the top of the extractive distillation regeneration tower is used as the raw material (the sulfur content is 304.90ug / g), and sulfolane and N,N dimethylformamide are used as the extraction agent, and the ratio of agent to oil is 2:1. Under pressure conditions, after extraction and rectification, when the cut point is 30°C, the measured distillate sulfur content is 7.60ug / g, which is 97.51% lower than that of Comparative Example 1; when the cut point is 40°C, the measured distillate The sulfur content of the product was 30.70ug / g, which was 89.93% lower than that of Comparative Example 1.

Embodiment 2

[0027] The extractive distillation recovery oil obtained from the top of the extractive distillation regeneration tower is used as the raw material (the sulfur content is 304.90ug / g), and sulfolane and N,N dimethylformamide are used as the extraction agent, and the ratio of agent to oil is 2:1. Under pressure conditions, after two-stage extraction and rectification, when the cut point is 30°C, the sulfur content of the distillate is 4.36ug / g, which is 98.57% lower than that of Comparative Example 1; when the cut point is 40°C, the measured The sulfur content of the distillate was 21.90ug / g, which was 92.82% lower than that of Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com