Warm mix asphalt additive, warm mix asphalt, preparation method and application

A technology of warm mix asphalt and additives, which is applied in the field of warm mix asphalt additives, warm mix asphalt and warm mix asphalt mixture and its preparation. The risk of damage and low-temperature cracking, the simple preparation process, and the effect of energy saving and emission reduction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

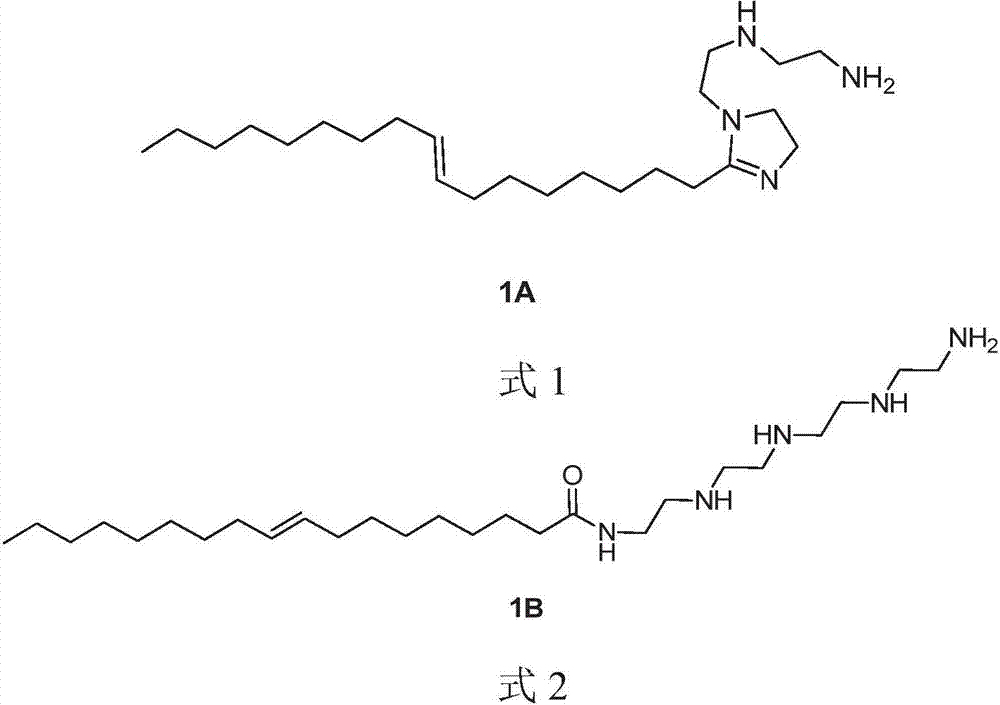

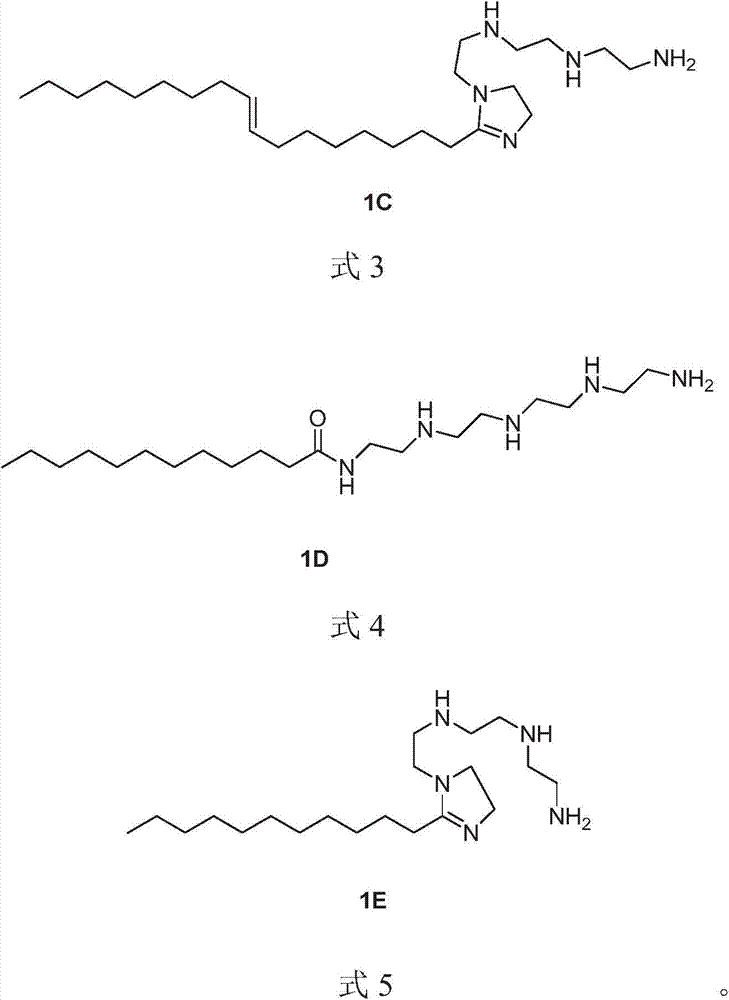

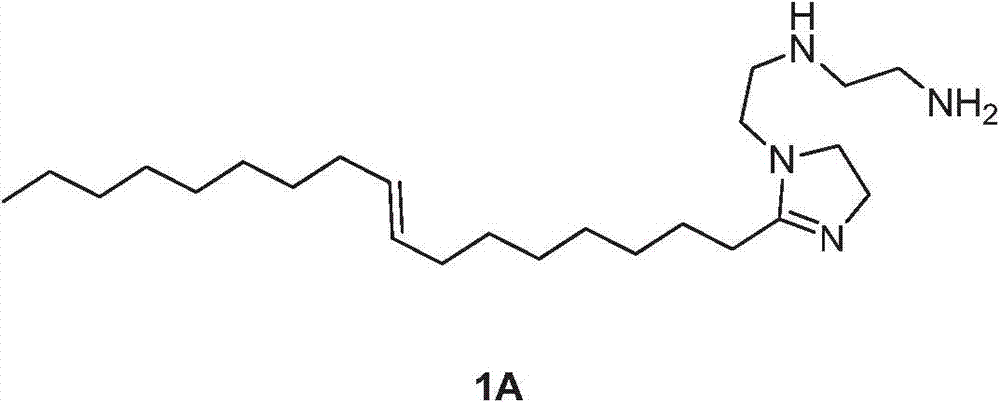

[0052] Preparation of warm-mix asphalt additive: Weigh oleic acid and triethylenetetramine to react, the reaction is a conventional reaction in the field, specifically as follows: oleic acid and triethylenetetramine are mixed in a molar ratio of 1:1 and heated to 260°C , and nitrogen dehydration to obtain fatty imidazoline-based polyamine compound 1A. Take 150g of the reaction product and put it into a 1000mL three-neck flask, heat it up to 40°C with stirring, then add 275g of ethylene oxide adduct ETHODUOMEEN T / 25 of tallow propylenediamine, and finally add 75g of polyethylene Based polyamine ECA-29, stirred for 1 hour to obtain the product, Warm Mix Asphalt Additive 2A.

[0053]

[0054] Preparation of warm-mix asphalt: Take warm-mix asphalt additive 2A with an asphalt quality of 5‰, add it to molten 70# petroleum asphalt, heat to 135°C and stir for 20 minutes to obtain warm-mix asphalt.

[0055] Preparation of warm-mix asphalt mixture: heat the obtained warm-mix asphalt...

Embodiment 2

[0058] Preparation of warm-mix asphalt additive: Weigh oleic acid and tetraethylenepentamine to react, the reaction is a conventional reaction in the field, specifically as follows: mix oleic acid and tetraethylenepentamine in a molar ratio of 1:1, and heat to 180°C , and nitrogen dehydration to obtain fatty amidopolyamine compound 1B. Get reaction product 350g and add in the three-neck flask of 1000mL, be heated to 40 ℃ with stirring, then add the ethylene oxide adduct Rhodoval CR-214 of the tallow propylenediamine of 100g (purchased from France Solvay company), Finally, 50 g of tetraethylenepentamine (purchased from Tosoh Corporation, Japan) was added and stirred for 1 h to obtain the product, Warm Mix Asphalt Additive 2B.

[0059]

[0060] Preparation of warm-mix asphalt: Take warm-mix asphalt additive 2B with an asphalt quality of 5‰, add it to molten 70# petroleum asphalt, heat to 135°C and stir for 20 minutes to obtain warm-mix asphalt.

[0061] Preparation of warm-m...

Embodiment 3

[0064] Preparation of warm-mix asphalt additive: Weigh oleic acid and tetraethylenepentamine to react, the reaction is a conventional reaction in the field, specifically as follows, oleic acid and tetraethylenepentamine are mixed in a molar ratio of 1:1, heated to 260°C, The fatty imidazoline-based polyamine compound 1C was obtained by dehydration under nitrogen gas. Get reaction product 300g and add in the three-necked flask of 1000mL, be accompanied by stirring to 35 ℃, then add the ethylene oxide adduct Rhodoval CR-215 of the tallow propylenediamine of 125g (from France Solvay company), finally add 75g of tetraethylenepentamine (from Japan Tosoh Corporation), stirred for 1 hour to obtain the product Warm Mix Asphalt Additive 2C.

[0065]

[0066]Preparation of warm-mix asphalt: Add warm-mix asphalt additive 2C, which accounts for 4‰ of asphalt mass, into molten 70# petroleum asphalt, heat to 135°C and stir for 20 minutes to obtain warm-mix asphalt.

[0067] Preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com