Method for degrading organic pollutants by using self oxygen supply and self acidification electro-Fenton system

A technology of organic pollutants and self-supplying oxygen, which is applied in the direction of water pollutants, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of electric Fenton system difficult to work, difficult air, lack of oxygen, etc., to save The effect of acidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

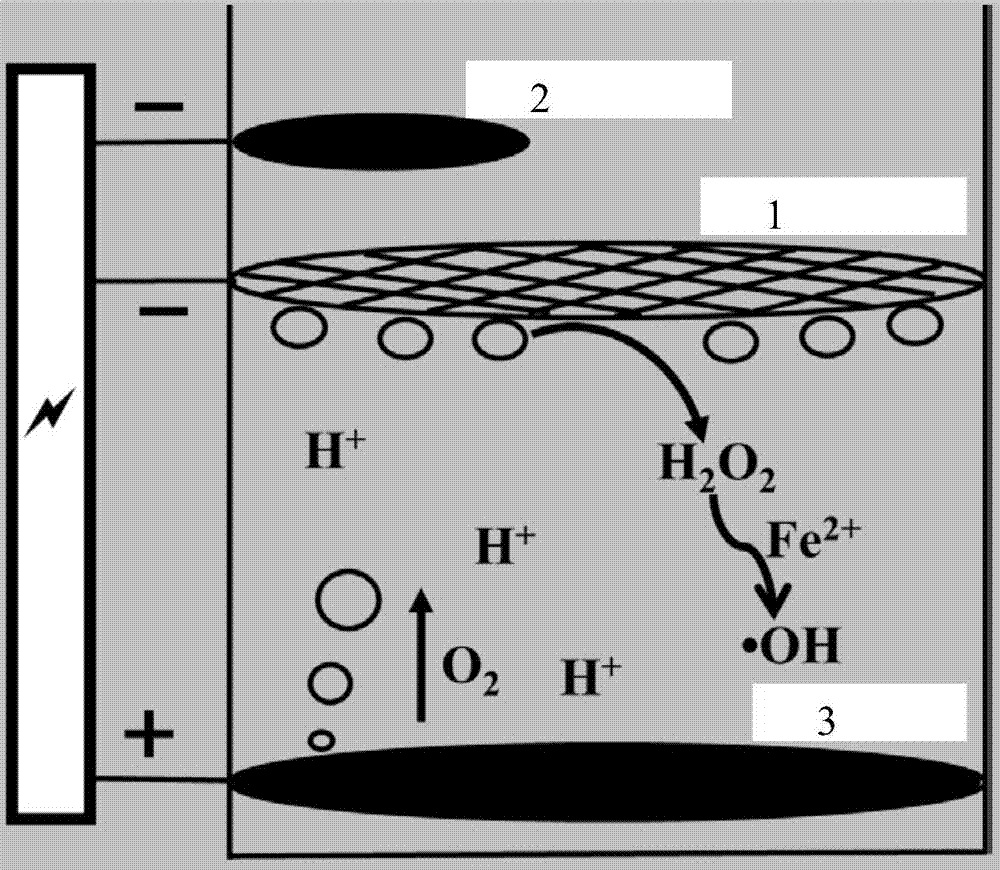

Method used

Image

Examples

Embodiment 1

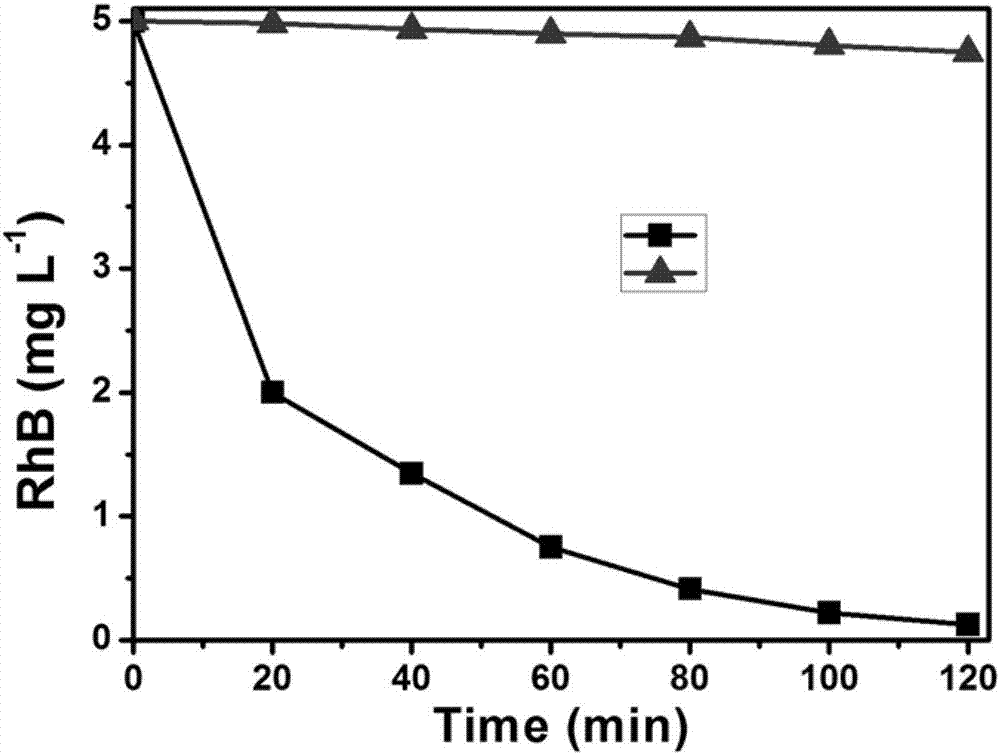

[0027] at 50mmolL -1 Na 2 SO 4 , 5mg L -1 Rhodamine B and 0.5mmol L -1 FeSO 4 In the neutral solution, use the power supply to supply power to the self-oxygenation and self-acidifying electro-Fenton system. The reduction cathode 2 adopts the hydrogen evolution cathode, the hydrogen evolution cathode adopts the constant current mode, and the constant current is -5mA, and the oxygen reduction cathode 1 adopts the constant voltage mode. , the constant voltage is -0.4V (relative to the Ag / AgCl reference electrode, after conversion, -0.21V relative to the potential of the standard hydrogen electrode), and the oxygen evolution anode is used as a common counter electrode. Take 1mL of samples every 20min, then inject 1mL of electrolyte solution containing Rhodamine B, repeat 7 times, and measure the solubility of Rhodamine B by spectrophotometry, as shown in figure 2 shown.

Embodiment 2

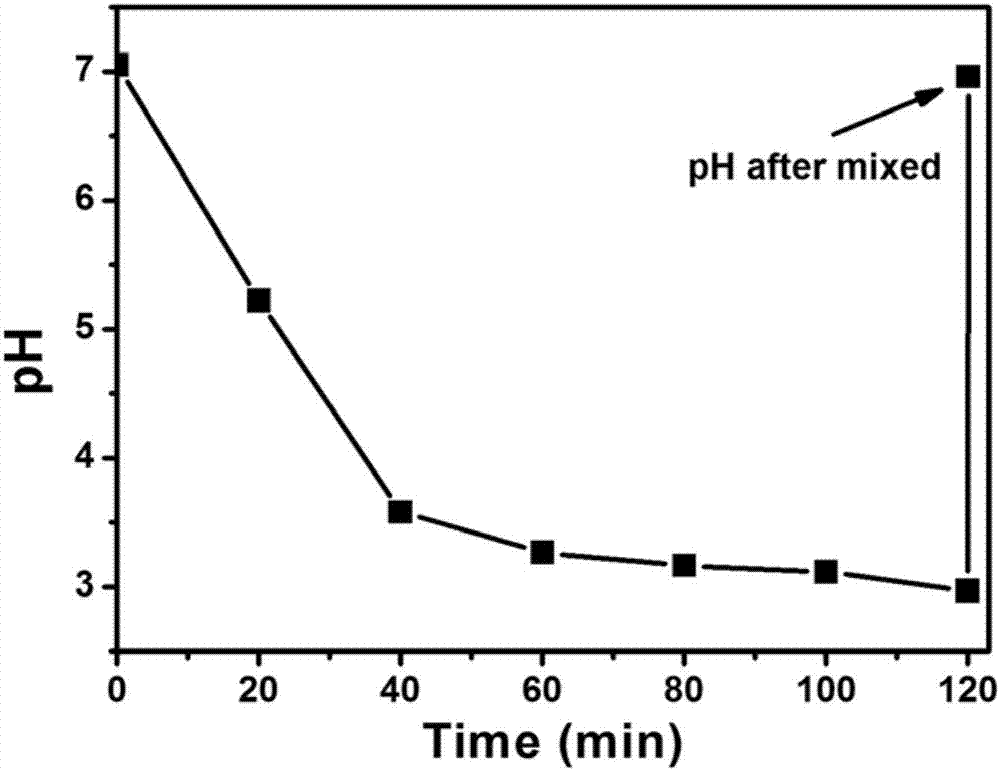

[0031] at 50mmolL -1 Na 2 SO 4 In the neutral solution, use the power supply to supply power to the self-oxygenation and self-acidifying electro-Fenton system. The reduction cathode 2 adopts the hydrogen evolution cathode, the hydrogen evolution cathode adopts the constant current mode, and the constant current is -5mA, and the oxygen reduction cathode 1 adopts the constant voltage mode. , the constant voltage is -0.4V (relative to the Ag / AgCl reference electrode, after conversion, -0.21V relative to the potential of the standard hydrogen electrode), and the oxygen evolution anode is used as a common counter electrode. Put the pH meter probe in the solution between the oxygen evolution anode and the oxygen reduction cathode 1, read the pH value every 20 minutes, and repeat 7 times. After 120min ends, pour the solution into a beaker and mix well, then measure the pH value again, as image 3 shown.

[0032] The results of Comprehensive Example 1 and Comparative Example 1 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com