Dust-removal material-sucking machine

A technology of suction machine and dust, applied in the direction of conveyor, conveying bulk materials, loading/unloading, etc., can solve the problems of cumbersome operation, high labor use, no dust removal facilities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

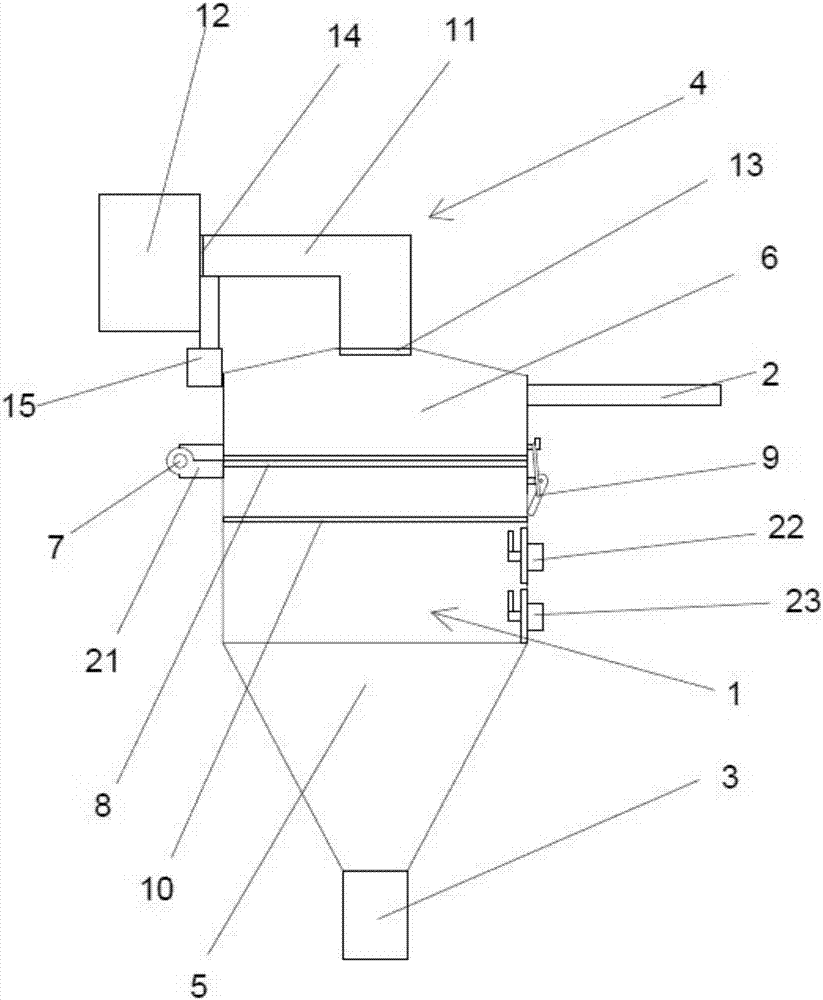

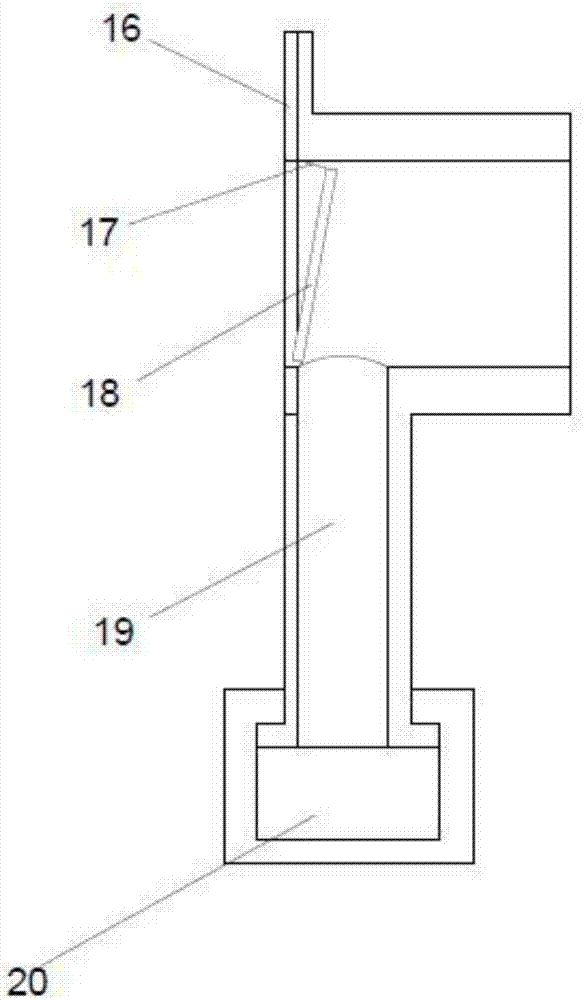

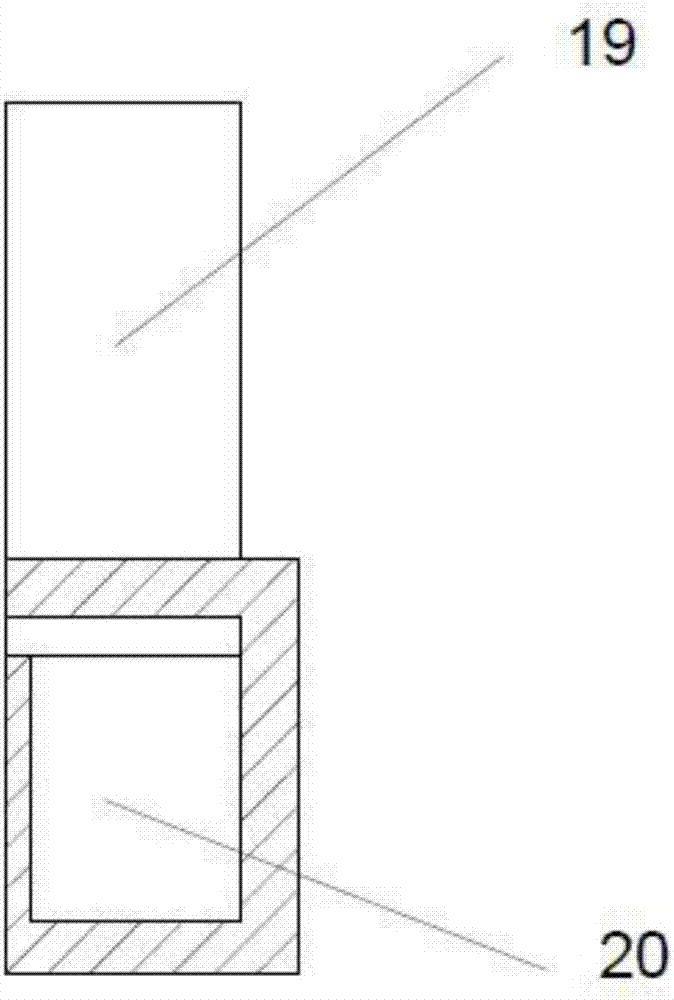

[0018] to combine Figure 1~3 As shown, the present embodiment provides a dust removal and suction machine, which includes a storage tank 1, the storage tank 1 includes a tank body 5 and a tank cover 6, the tank cover 6 is hingedly located at the tank body 5, and the tank cover 6 is connected to the tank body Locking parts 9 are provided between the tank body 5 and the hinge point; the side wall of the tank cover 6 is provided with a feed port 2, and the bottom of the tank body 5 is provided with a discharge port 3; the inside of the tank body 5 is provided with a filter screen 10 , the sieve hole of filter screen 10 can pass through for raw material; Tank cover 6 tops are provided with suction device 4, and suction device 4 comprises the suction pipe 11 that one end is connected with tank cover 6 tops, and suction pipe 11 other ends are provided with Air pump 12; a first filter screen 13 is provided at the connection between the suction pipe 11 and the tank cover 6, a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com