Filler sucking and discharging overhead crane for graphite refining

A technology of filler and graphite, applied in the direction of charge, furnace, charge composition/state, etc., can solve the problems of increasing the cooling burden of the suction crane, reducing the cooling efficiency, prolonging the cooling time, etc., to expand the scope of application of the suction temperature, Improve the cooling effect and ensure the effect of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings in the embodiments of the present invention. In the description, it should be understood ", "Right" and other indicated orientations or positional relationships are only corresponding to the drawings of the present invention. In order to facilitate the description of the present invention, they do not indicate or imply that the referred device or element must have a specific orientation:

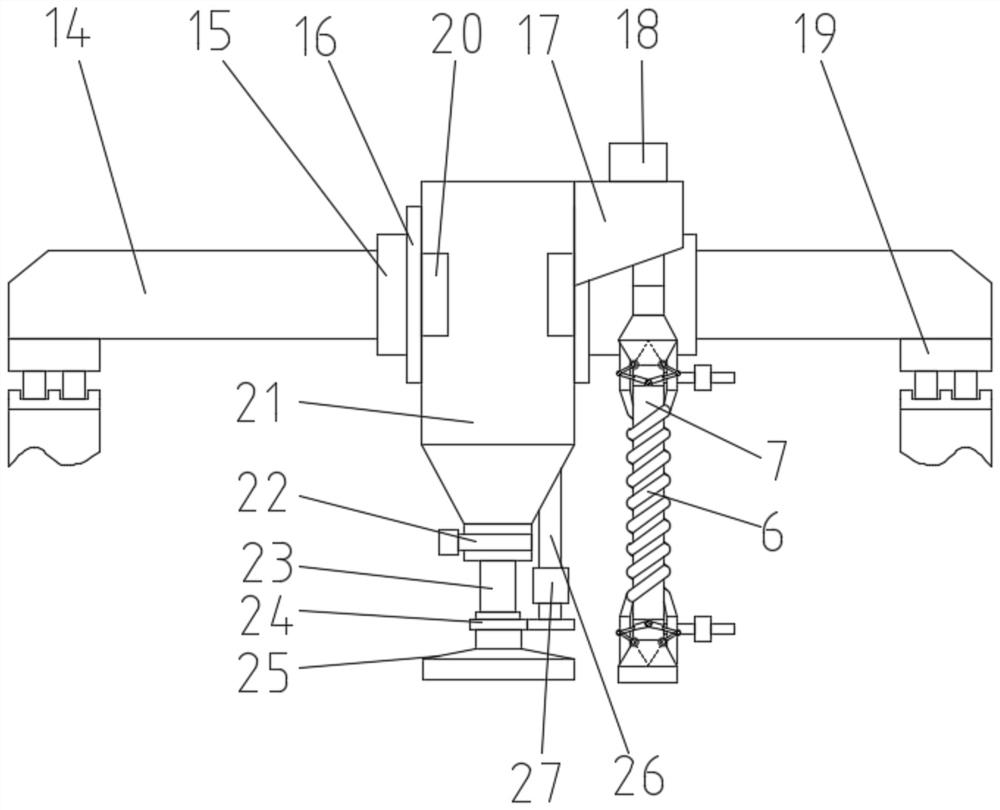

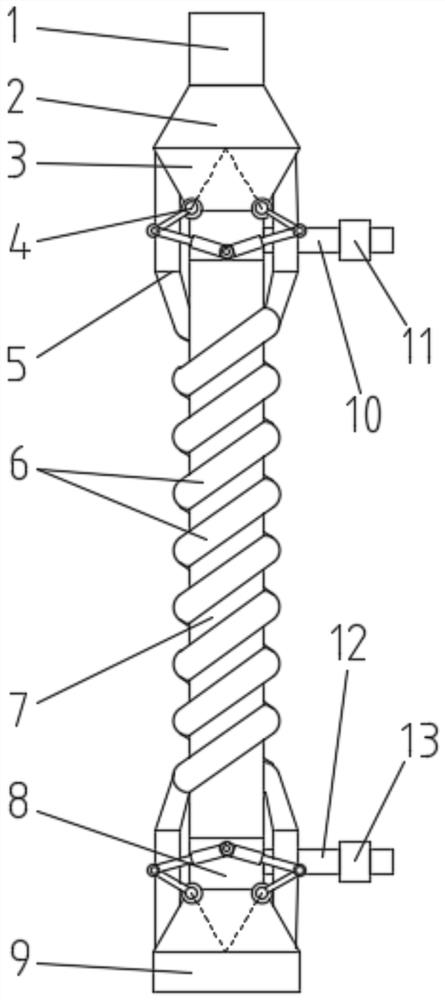

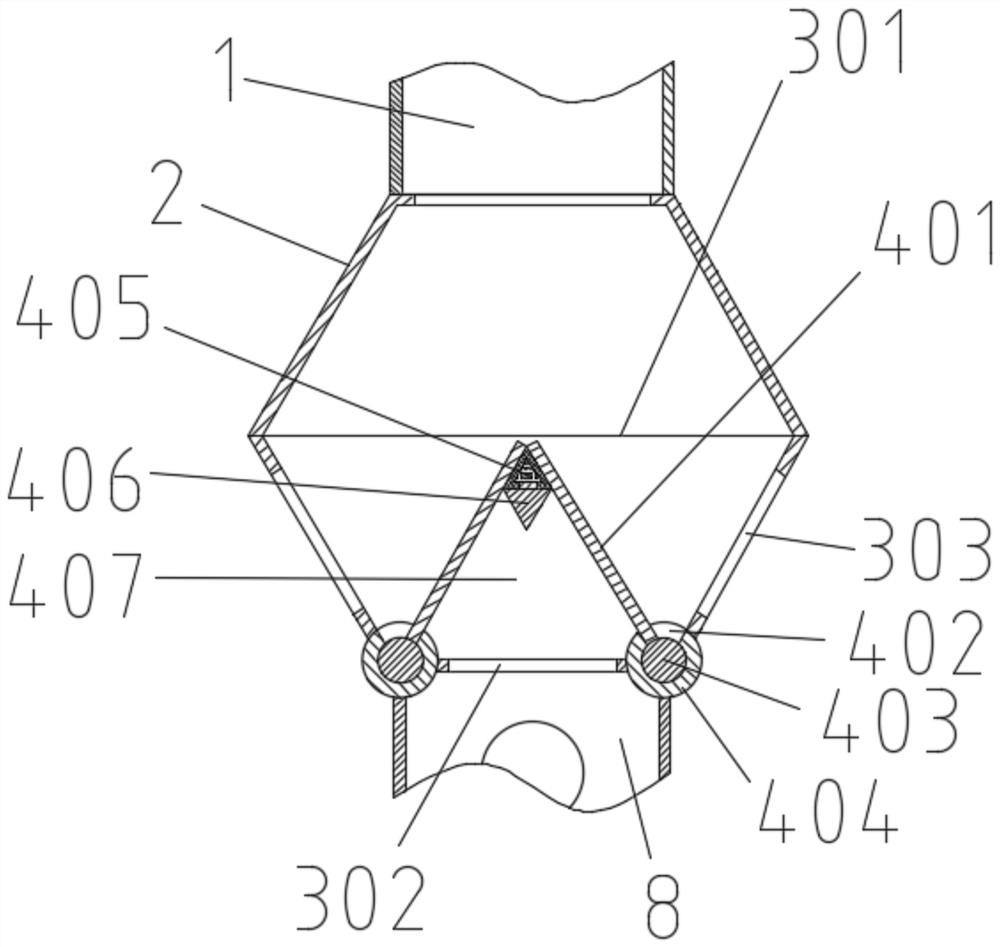

[0027] combined with Figure 1-7 The described graphite-refined filling material suction and discharge crane comprises a main beam 14, a trolley frame 15, a discharge bin 21, a discharge pipe 23 and a buffer bin 17, and two ends of the main beam 14 are installed respectively. A cart operating mechanism 19 can drive the main beam 14 to move laterally along it through the cart operating mechanism 19. The trolley frame 15 is installed on the main beam 14 and can move axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com