Bagged powder or particle material hoisting and taking system

A granular and powdered technology, which is applied in the field of fully automatic fertilizer vending machines, can solve the problems that affect the working efficiency of the service life of the mechanism, the damage and scrap of the servo motor, the deflection of lifting and retrieving materials, etc., and achieve flexible telescopic movement of the mechanism and significant anti-swing effect , the effect of improving the running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention will be described in detail below with reference to the accompanying drawings.

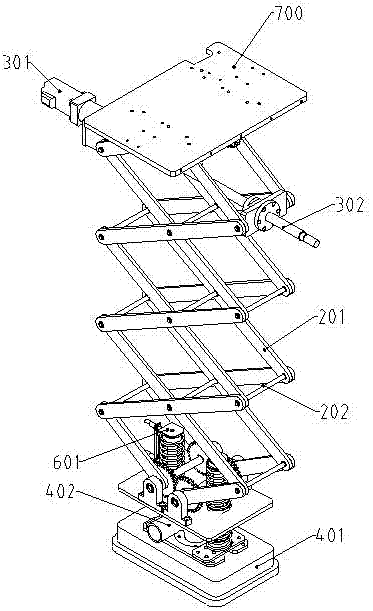

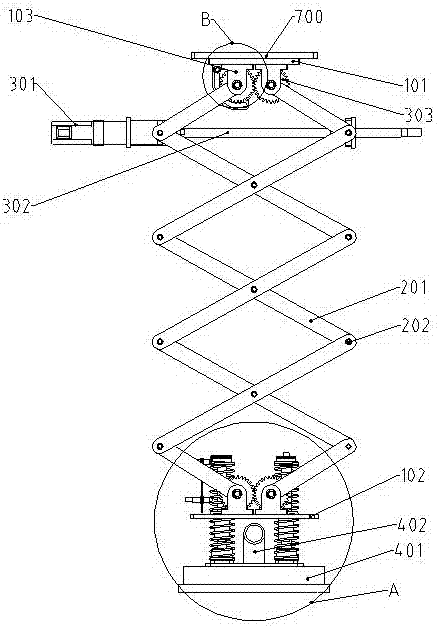

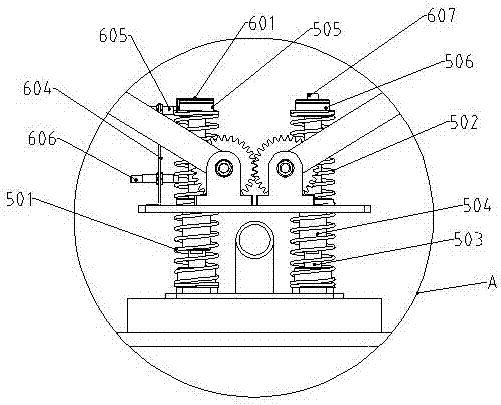

[0022] Such as Figure 1-4 Shown is a powder or granular bagged material lifting and reclaiming system of the present invention, which includes a lifting component, a lifting installation component and a reclaiming component.

[0023] The lifting installation assembly includes a top mounting plate 101 and a bottom mounting plate 102; the top mounting plate 101 is connected to the mechanism top beam 700; the lifting assembly is installed on the mechanism top beam 700 through the top mounting plate 101; the reclaiming component is mounted on the bottom mounting plate 102 is connected with the lifting assembly;

[0024] The lifting assembly includes a driving device and a scissor device. The drive device drives the scissor fork to expand and contract; the scissor device includes two sets of scissor forks 201 and a connecting rod 202 arranged oppositely; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com