Riser later-period machining and production technological process

A production process and riser technology, which is applied to metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of undisclosed riser production process, etc., and achieve low worker operation intensity, high work efficiency, and improved quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

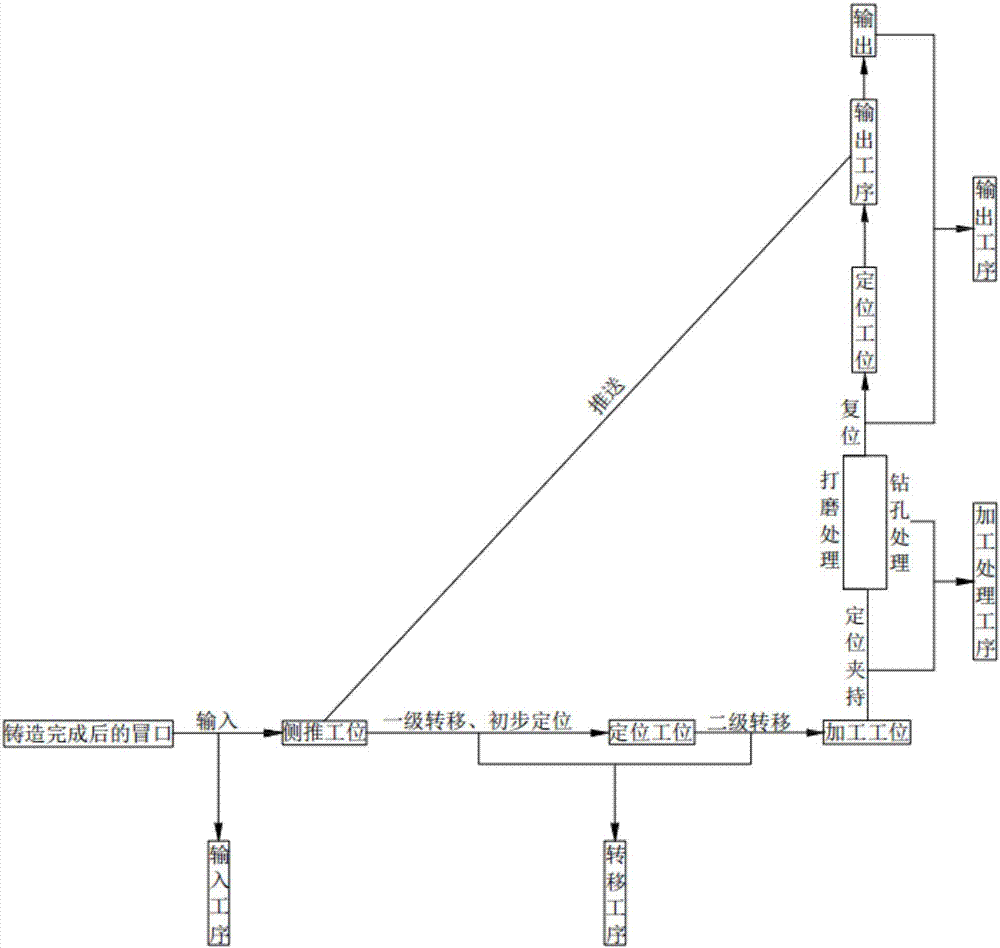

[0094] like figure 1 As shown, a riser post-processing production process includes the following steps:

[0095] Step 1, the input process, linearly arrange the risers after casting on the input assembly 22, and transfer them to the side pushing stations one by one;

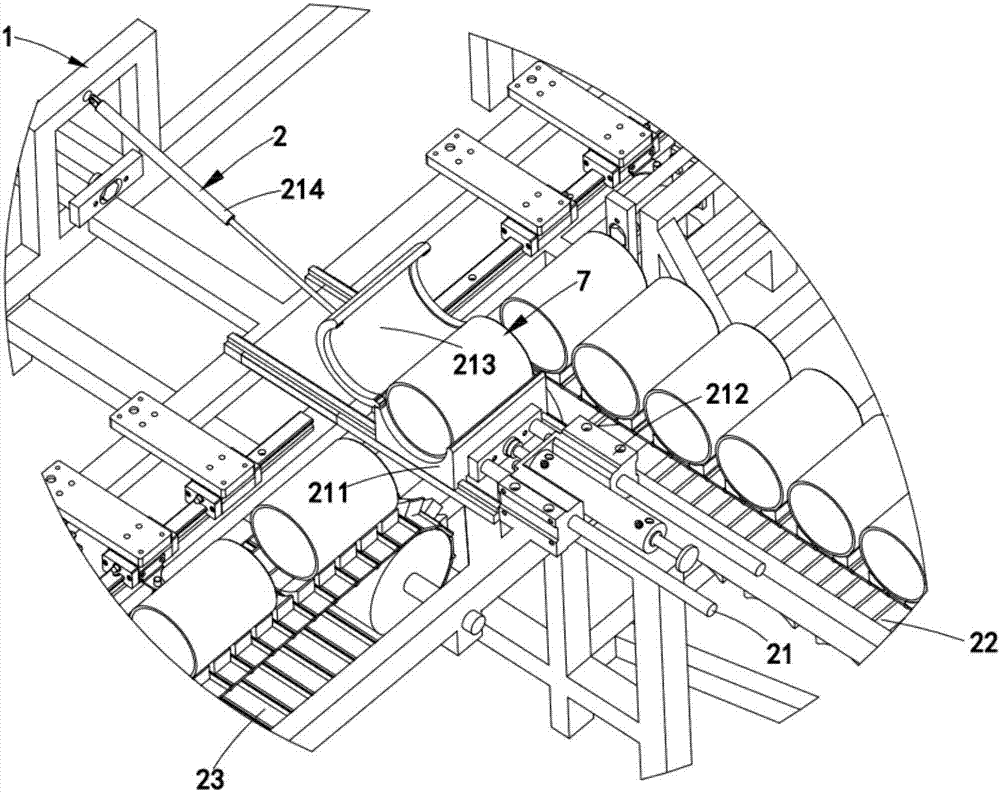

[0096] Step 2, transfer process, push the riser at the side pushing station to the positioning station through the side pushing cylinder 223, complete the preliminary positioning and first-level transfer of the riser, and then push the riser to the processing worker through the positioning assembly 21 position, to complete the secondary transfer of the riser;

[0097] Step 3, the processing procedure, the riser at the processing station is positioned and clamped by the positioning assembly 21, and then the grinding and drilling of the riser are completed;

[0098] Step 4, the output process, the positioning assembly 21 is reset synchronously, and the riser that has been processed in step 3 is brought back to th...

Embodiment approach

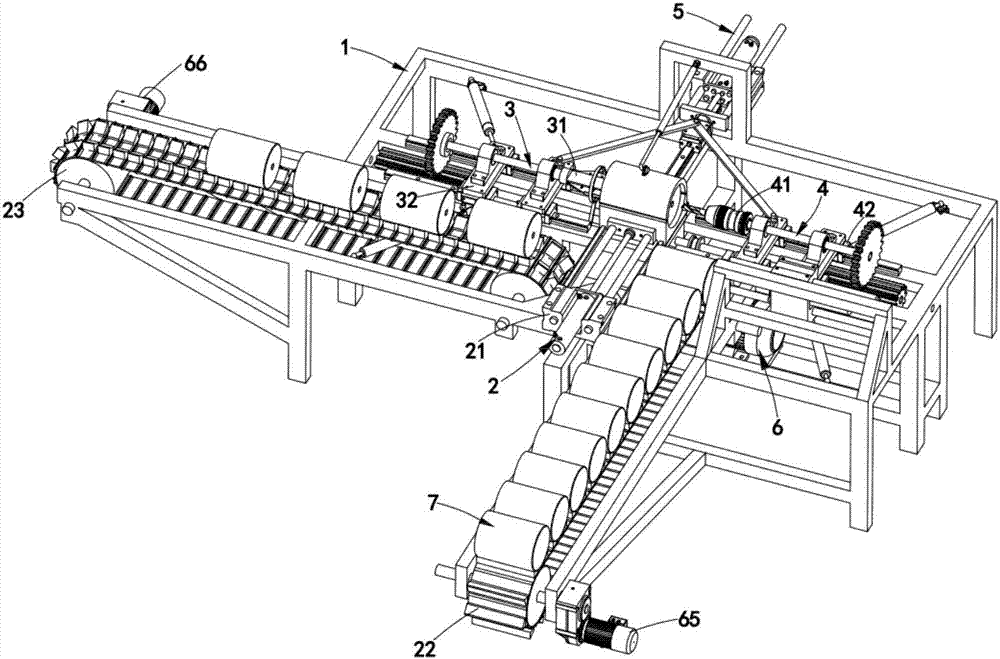

[0171] like Figure 13 As shown, as a preferred embodiment, the drive mechanism 6 includes:

[0172] The first driving motor 61, the driving motor 61 is fixedly arranged on the frame 1, and it is located below the drilling mechanism 4;

[0173] Transmission shaft 62, the transmission shaft 62 is rotatably arranged on the frame 1, it is located below the grinding mechanism 3 and the drilling mechanism 4, and the middle part thereof is connected with the first drive motor 61 by means of belt transmission;

[0174] The first gear set 63, the first gear set 63 is located at the end of one side of the transmission shaft 62, which is used to connect the transmission shaft 62 and the grinding assembly 31;

[0175] The second gear set 64, the second gear set 64 is arranged at the other end of the transmission shaft 62 relative to the first gear set 63;

[0176] The second drive motor 65, the second drive motor 65 is arranged at the end of the input assembly 22, and it is used to dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com