Compound low sodium salt and preparation method thereof

A low-sodium salt and sodium chloride technology, applied in food ingredients as taste improvers, food shaping, food science, etc., can solve the problem of changing the salty taste of sodium chloride, increasing the amount of use, poor acceptability of low-sodium salt, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing compound low-sodium salt, comprising the following steps:

[0022] (1) Potassium chloride, flavor masking agent and maltodextrin are mixed to obtain taste-masking potassium chloride;

[0023] (2) mixing the taste-masking potassium chloride obtained in the step (1) with calcium source, amino acid, sodium glutamate and sodium chloride to obtain a compound low-sodium salt; the amino acid includes alanine;

[0024] The mass contents of the potassium chloride, flavor masking agent, maltodextrin, calcium source, amino acid, sodium glutamate and sodium chloride are as follows: potassium chloride 20-25%, flavor improving agent 0.5-1%, calcium source 0.2-0.5%, maltodextrin 5-8%, amino acid 1.5-5%, sodium glutamate 1-2% and the balance sodium chloride.

[0025] The invention mixes potassium chloride, flavor masking agent and maltodextrin to obtain taste masking potassium chloride.

[0026] In the present invention, based on the tota...

Embodiment 1

[0047] Prepare raw material components according to the following ratio: 20% potassium chloride, 0.5% citric acid, 0.2% calcium lactate, 5% maltodextrin with a DE value of 13%, 1% L-lysine, and 0.5% L-alanine , sodium glutamate 1%, the balance is sodium chloride, wherein each raw material is selected food grade.

[0048] Mix and dissolve potassium chloride and citric acid in water, the amount of water used ensures that the concentration of potassium chloride is 320g / L, and then mix maltodextrin with the solution to form a taste-masking potassium chloride solution, and store it at 80°C Spray-dried for 20 minutes at lower temperature to obtain taste-masking potassium chloride. Mix the dried taste-masking potassium chloride with sodium chloride, calcium lactate, L-lysine, L-alanine, and sodium glutamate at 800rpm for 10 minutes, then grind it into a particle size of not more than 0.3mm Compound low sodium salt.

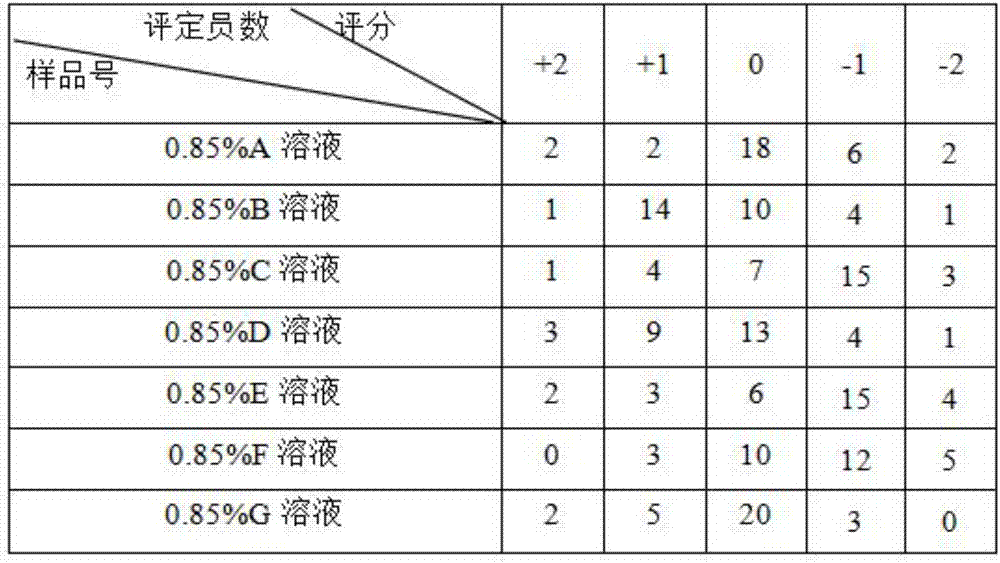

[0049] The prepared compound low-sodium salt was observed through...

Embodiment 2

[0051] Prepare raw material components according to the following ratio: 23% potassium chloride, 1% citric acid, 0.5% calcium lactate, 8% maltodextrin with a DE value of 15%, 3% L-lysine, and 2% L-alanine , sodium glutamate 2%, the balance is sodium chloride, wherein each raw material is selected food grade.

[0052] Mix and dissolve potassium chloride and citric acid in water, the amount of water used shall ensure that the concentration of potassium chloride is 330g / L, and then mix maltodextrin with the solution to form a taste-masking potassium chloride solution, and then store it at 70°C Spray-dried for 20 minutes under the same conditions to obtain taste-masked potassium chloride. Mix the dried taste-masking potassium chloride with sodium chloride, calcium lactate, L-lysine, L-alanine, and sodium glutamate at 500rpm for 5 minutes, then grind them into particles with a particle size of no more than 0.2mm. Compound low sodium salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com