Bean flour humidifier

A technology for humidifiers and bean flour, which is applied to mixers, mixers with rotating stirring devices, and dissolving, etc. It can solve the problems of prone to agglomeration and lumps, uneven watering of bean flour, and product quality decline, and achieves Simple structure, reasonable design, solve the effect of humidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

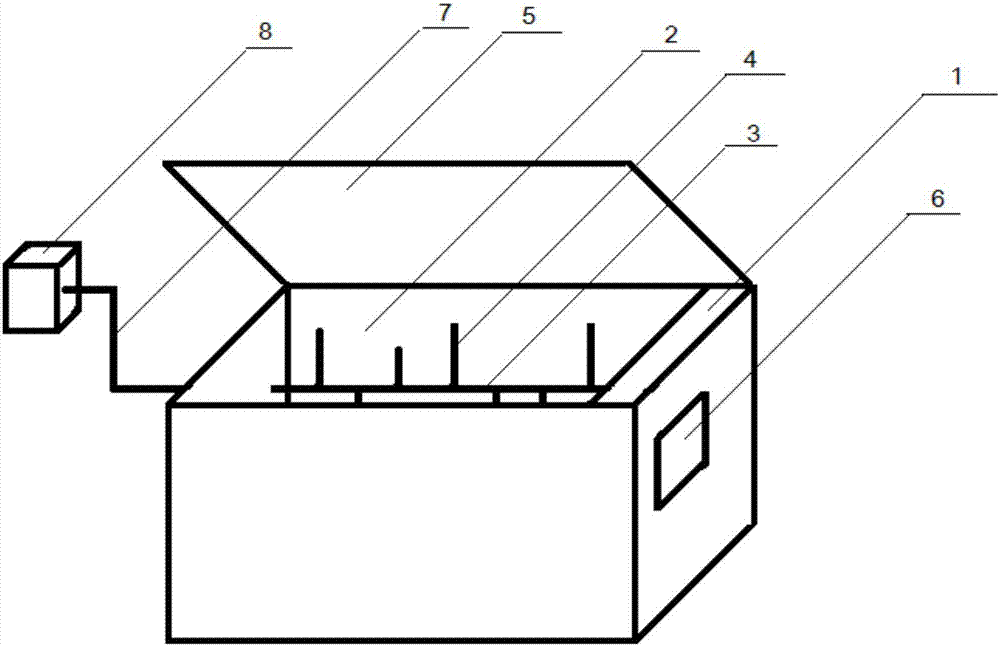

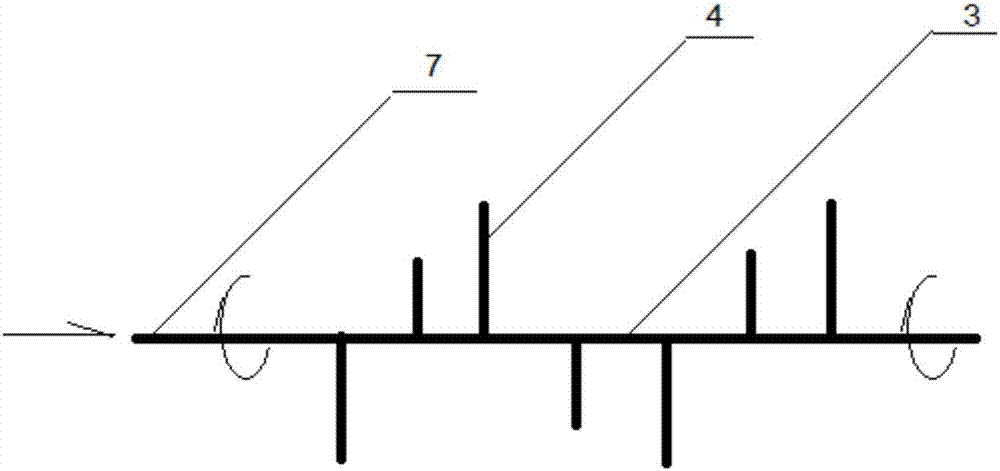

[0012] Example 1: A soy flour humidifier. The main body 1 of the humidifier is provided with a mixing chamber 2 and a cover plate 5. The mixing chamber 2 is provided with a stirring shaft 3 fixed in it by a bearing, and one end of the stirring shaft 3 is connected to The motor 6 provided with power, the stirring shaft 3 is provided with a stirring rod 4 for stirring the soybean flour, the stirring shaft 3 and the stirring rod 4 are hollow and communicate with each other, and the other end of the stirring shaft 3 is connected to the storage by a steam pipe 7 In the gas tank 8 for storing water vapor, the stirring rod 4 is provided with small holes, and the water vapor from the gas storage tank 8 enters the stirred soybean powder through the small holes on the steam pipe 7, the stirring shaft 3 and the stirring rod 4.

Example Embodiment

[0013] Example 2: A soybean flour humidifier. The main body 1 of the humidifier is provided with a mixing chamber 2 and a cover plate 5. The mixing chamber 2 is provided with a stirring shaft 3 fixed in it by a bearing, and one end of the stirring shaft 3 is connected to The motor 6 provided with power, the stirring shaft 3 is provided with a stirring rod 4 for stirring the soybean flour, the stirring shaft 3 and the stirring rod 4 are hollow and communicate with each other, and the other end of the stirring shaft 3 is connected to the storage by a steam pipe 7 The gas tank 8 for storing water vapor is provided with small holes on the stirring rod 4, and the water vapor from the gas storage tank 8 enters the stirred soybean powder through the small holes on the steam pipe 7, the stirring shaft 3 and the stirring rod 4. The mixing chamber 2, the stirring shaft 3, the stirring rod 4 and the cover 5 are made of stainless steel.

Example Embodiment

[0014] Example 3: A soy flour humidifier. The main body 1 of the humidifier is provided with a mixing chamber 2 and a cover plate 5. The mixing chamber 2 is provided with a stirring shaft 3 fixed in it by a bearing, and one end of the stirring shaft 3 is connected to The motor 6 provided with power, the stirring shaft 3 is provided with a stirring rod 4 for stirring the soybean flour, the stirring shaft 3 and the stirring rod 4 are hollow and communicate with each other, and the other end of the stirring shaft 3 is connected to the storage by a steam pipe 7 In the gas tank 8 for storing water vapor, the stirring rod 4 is provided with small holes, and the water vapor from the gas storage tank 8 enters the stirred soybean powder through the small holes on the steam pipe 7, the stirring shaft 3 and the stirring rod 4. The mixing chamber 2, the stirring shaft 3, the stirring rod 4 and the cover 5 are made of stainless steel. Both ends of the mixing shaft 3 are provided with food-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com