Combined insulating end cover for wind driven generator

A wind turbine and combined insulation technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of poor insulation of wind turbine end covers, and achieve excellent performance, thick insulation thickness and short manufacturing cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

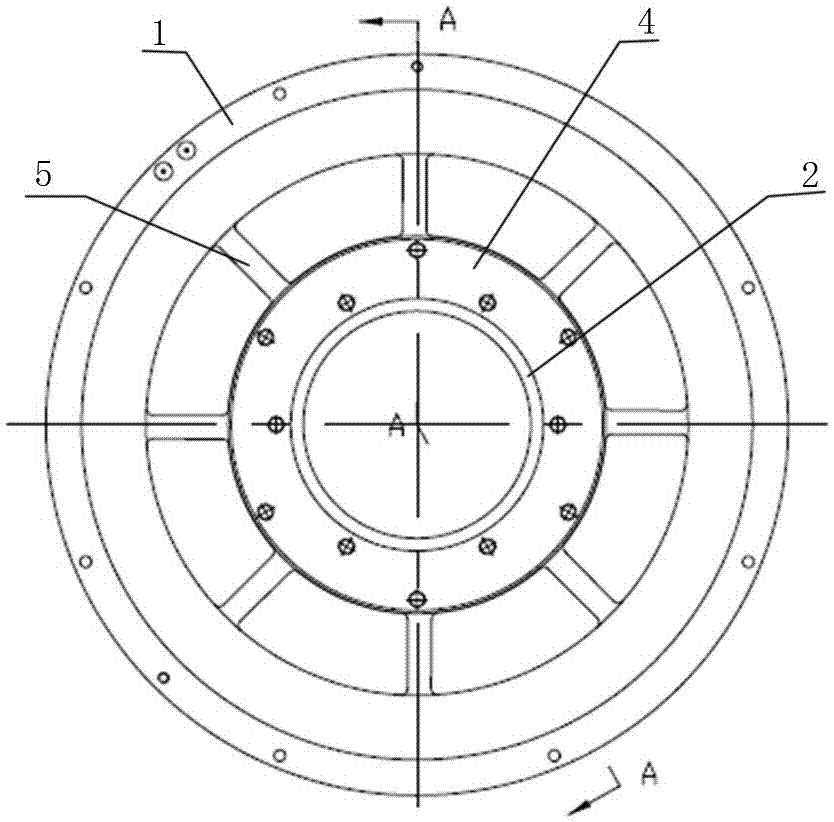

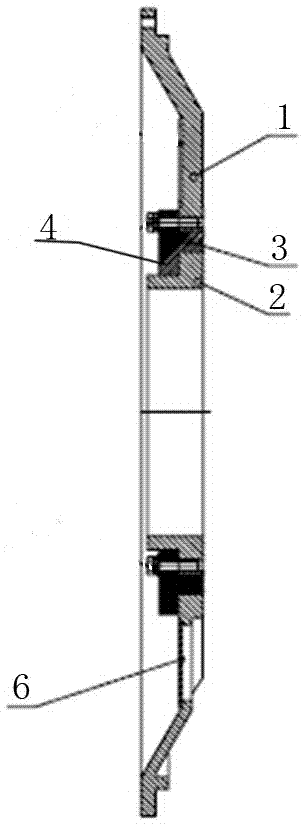

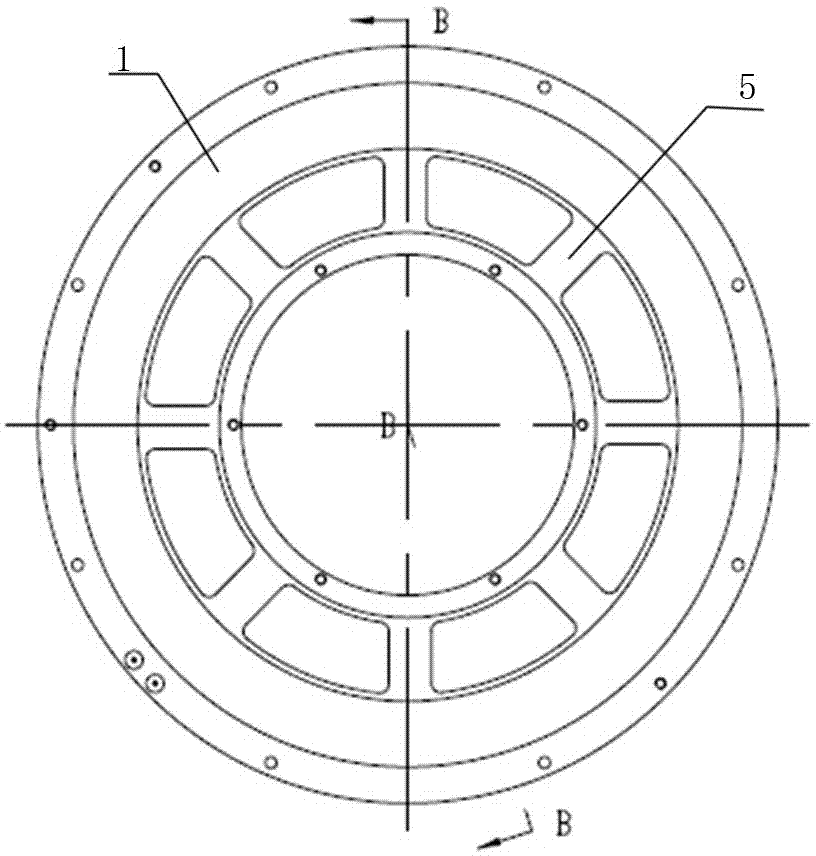

[0011] The combined insulating end cover of the wind power generator includes the end cover body 1 and the bearing chamber 2; the inherent insulating connecting ring 3 is set between the end cover body 1 and the bearing chamber 2, that is, the inner ring surface of the end cover body 1 is sleeved on the insulating connection The outer ring surface of the ring 3 and the inner ring surface of the insulating connection ring 3 are sleeved on the outer ring surface of the bearing chamber 2 . The bearing chamber 2 is axially single-stepped, and the outer end face of the insulating connecting ring 3 is flush with the outer end faces of the end cover body 1 and the bearing chamber 2, thus ensuring that the insulating connecting ring 3 can only be sleeved in the large part of the bearing chamber 2. On the outer ring surface (the outer ring surface of the axially single-stepped bearing chamber is divided into large and small). In order to realize the fastening between the insulating con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com