High-resolution large-target surface machine vision lens

A machine vision, high-resolution technology, applied in the lens field, can solve problems such as unsatisfactory and edge image quality degradation, and achieve high resolution, small size, and excellent imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

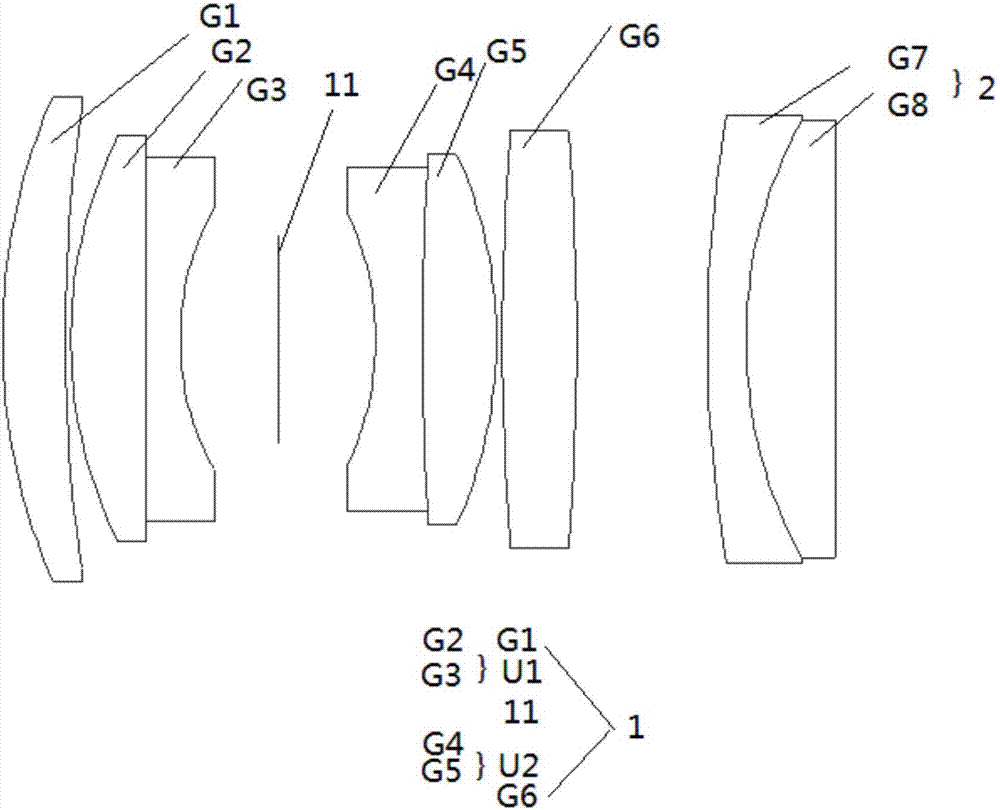

[0030] Please refer to figure 1 , a high-resolution large-target surface machine vision lens of the present invention includes: a focusing group 1 and a fixed group 2 in sequence along the light incident direction. Wherein, the focusing group 1 is at the end close to the object plane, and the fixed group 2 is at the end close to the image plane. The position of the fixed group 2 relative to the image plane is fixed, that is, the optical back focus remains unchanged. When the working distance changes, The best image plane can be found by moving the focusing group 1 back and forth.

[0031] Specifically, the focusing group 1 sequentially includes: a first lens G1, a first cemented lens group U1, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com