High-voltage explosion-proof battery pack and manufacturing method of battery pack

A manufacturing method and technology for battery packs, which are applied in secondary battery manufacturing, battery pack components, and final product manufacturing, etc., can solve problems such as high product development costs, easy short-circuiting of cells, and inability to standardize the connection of nickel strips. Reduce the probability of mis-soldering and short circuit, improve the safety of production operations, and achieve the effect of standardization and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

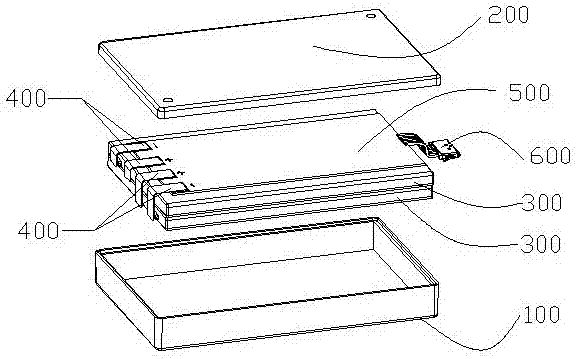

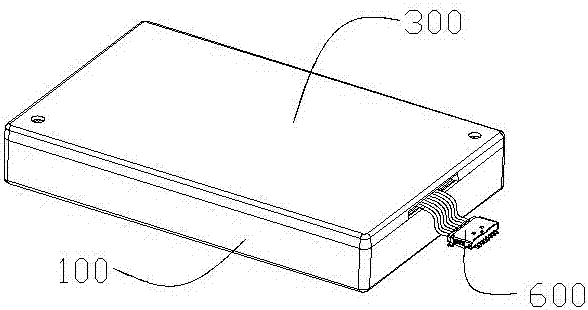

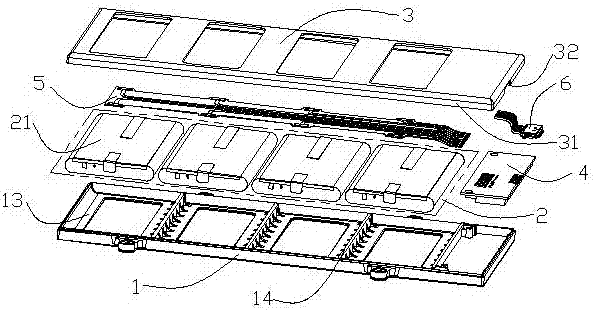

[0042] Please refer to Figure 3 to Figure 9 , is a structural schematic diagram of the high-voltage explosion-proof battery pack of the present invention. The explosion-proof battery pack includes a battery box 1, a cell pack 2, a cover 3, a rigid circuit board 4, a flexible circuit board 5 and an external connector 6, and the cell pack 2 includes four The electric core 21, the electric core 21 is fixed in the described battery case 1 at intervals, one end of the flexible circuit board 5 is connected with the rigid circuit board 4, and the other end is connected with the electric core group 2 phases are connected, the battery cells 21 are connected in series, the rigid circuit board 4 and the flexible circuit board 5 are both accommodated in the battery box 1, and the battery box 1 is a cuboid accommodating space , the battery pack 2 is located at one end of the cuboid accommodating space, and the rigid circuit board 4 is located at the other end of the cuboid accommodating ...

Embodiment 2

[0055] Please refer to Figure 10 , is another embodiment of the present application, which is a method for assembling and manufacturing a high-voltage explosion-proof battery pack, which specifically includes the following steps:

[0056] S1, provide four electric cores, and insulate the positive and negative poles of the electric cores, so that the positive and negative poles of the electric cores are fully isolated;

[0057] S2, extending a positive electrode welding strip and a negative electrode welding strip from the positive electrode and the negative electrode of the battery cell by nickel strip welding; in this step, the positive electrode welding strip and the negative electrode welding strip are an independent A strip-shaped nickel strip, and the strip-shaped nickel strip is respectively connected to the positive pole and the negative pole of the battery cell by welding;

[0058] S3, providing a flexible circuit board, connecting the battery cells into multiple ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com