Prism structure of optical machine

A prism and light-mechanical technology, applied in the field of projectors, can solve the problems of cumbersome, prism imaging, easy out of focus, debugging and assembly process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The core of the present invention is to provide an optical-mechanical triangular prism structure, so as to avoid the problems that the triangular prism image is easily out of focus and the debugging and assembly process is cumbersome.

[0027] In order to enable those skilled in the art to better understand the technical solutions provided by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

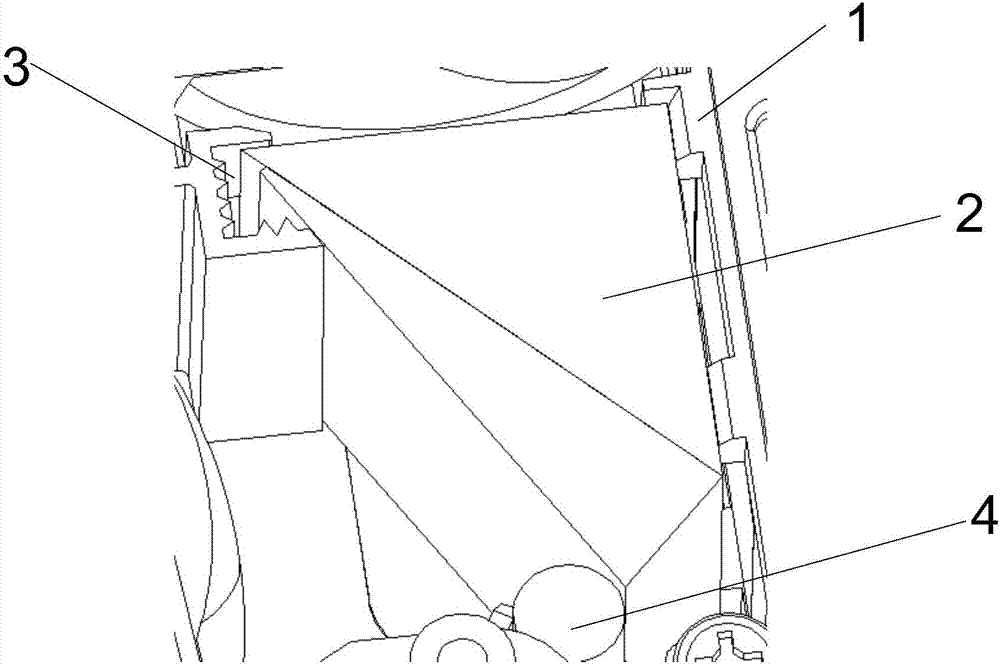

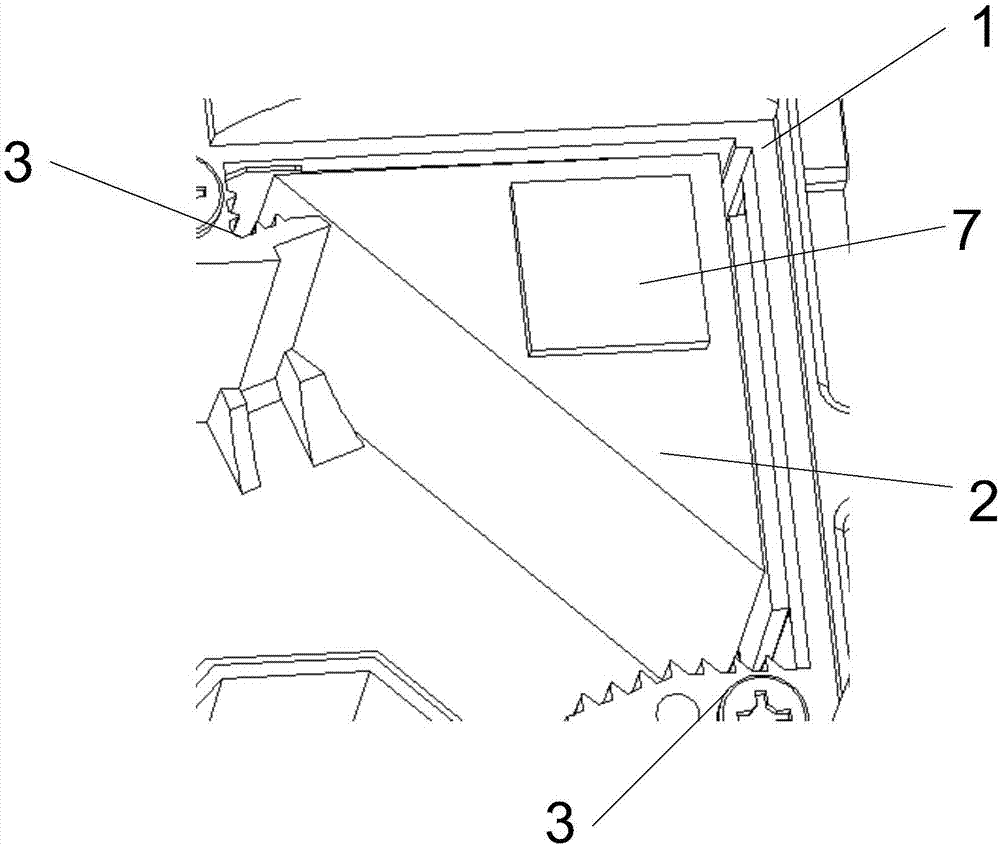

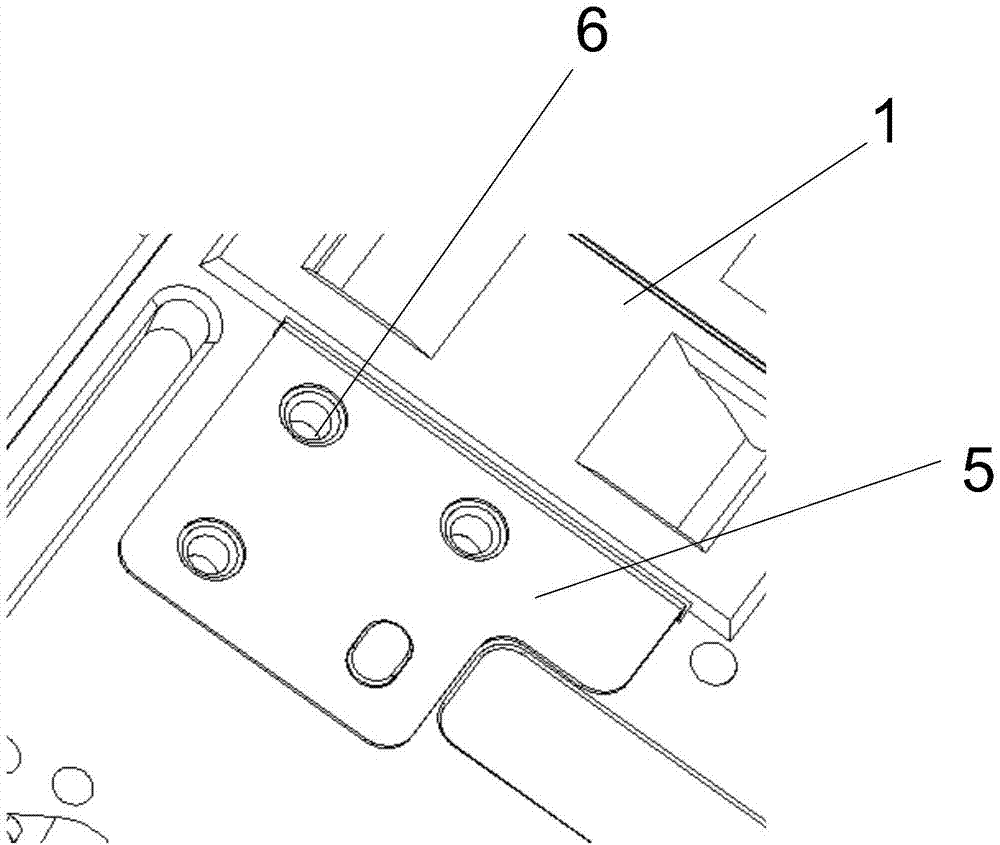

[0028] Such as Figure 4-Figure 7 As shown, the prism structure of an optical machine provided by the embodiment of the present invention includes an optical machine body 1 and a prism 2 fixed on the optical machine body 1. The optical machine body 1 is provided with a first bearing surface 8, a second Abutment surface 9 and limit surface 10; the first abutment surface 8 fits with the first side of the prism 2, the second abutment surface 9 fits with the second side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com