Cross metal wire elastic modulus measuring device and method

An elastic modulus, metal wire technology, applied in the field of physical experimental instruments and experiments, can solve the problems of difficult adjustment of the optical system, difficult to obtain experimental results, complicated experimental operation, etc. The effect of a clear measurement principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

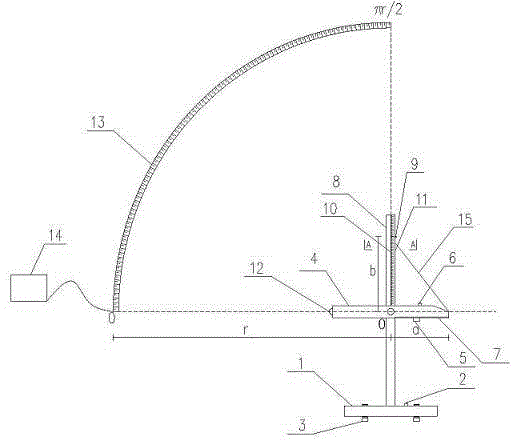

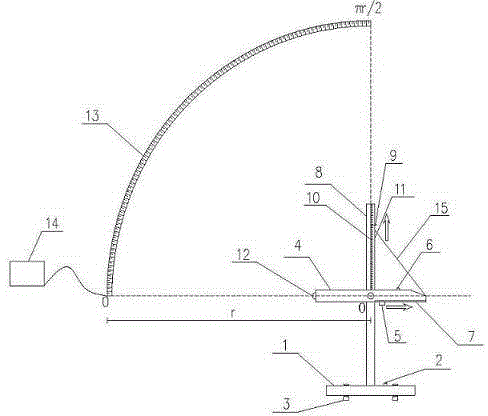

[0041] by figure 1 The illustrated embodiment is an example, and the implementation method of the cross-shaped wire elastic modulus measuring device of the present invention is as follows:

[0042]1) Move the leveling weight 5 to the side close to the hinge point O, adjust the foot screw 3 on the base 1, center the air bubble of the base level 2, and realize the level of the base 1, turn on the power of the laser transmitter 12, and turn on the arc Receive the power supply of screen 13 and display 14;

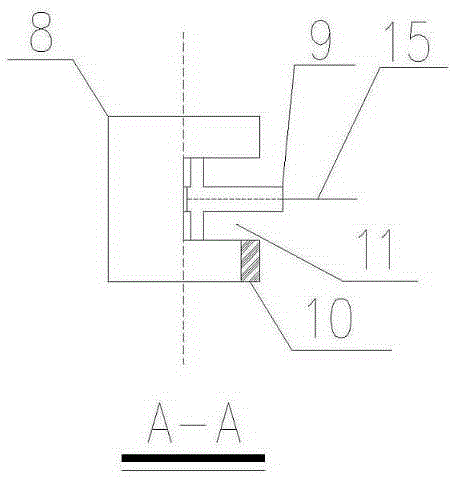

[0043] 2) if figure 1 with figure 2 As shown, select a section with a length approximately equal to The elastic modulus of the metal wire 15 to be measured makes one end of the metal wire 15 fixed on the right end of the cross bar 4, and the other end is connected on the slide screw 9;

[0044] 3) if image 3 As shown, move the sliding screw 9 upward along the vertical bar chute 7 to make the metal wire 15 gradually tense, observe the horizontal bar 4 with the naked eye ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com