A spatial cable system and optimization method for controlling wind turbine blade flapping

A technology for wind turbine blades and wind turbines, which is applied to wind turbines, wind turbines, motors and other directions that are consistent with the wind direction, and can solve problems such as self-weight, impact, and difficulty in running and generating electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

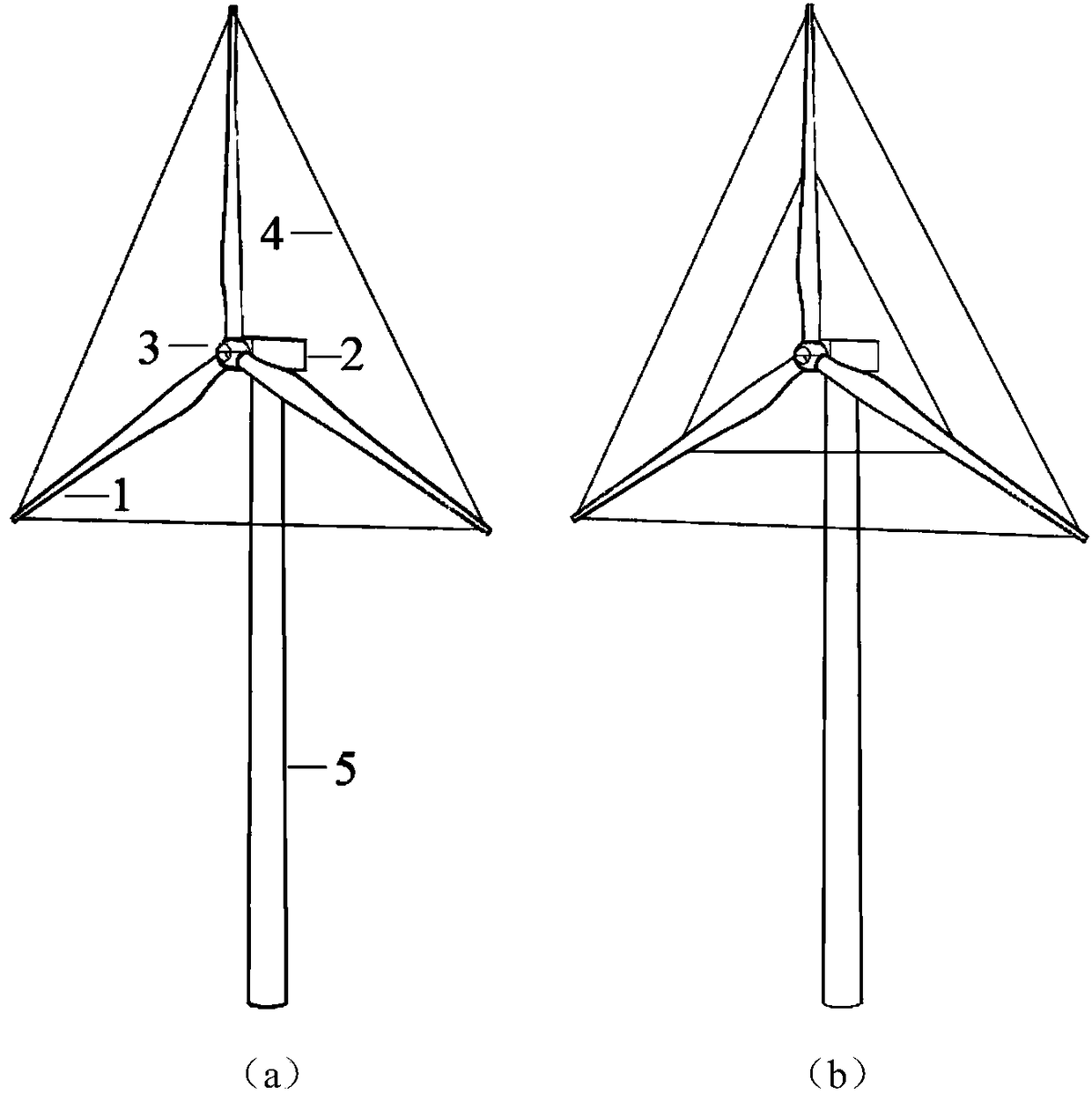

[0044] This embodiment takes a large horizontal axis wind turbine in China as an example, such as figure 1 As shown, the specific implementation steps are:

[0045] i) First anchor the three cables directly to the tips of the three blades, such as figure 1 (a) A static stator system without redundant degrees of freedom is formed, and the dynamic characteristic analysis is performed to obtain the fundamental frequency of the wind turbine system;

[0046] j) Establish a finite element model for the system and apply a preset wind pressure, on this basis, analyze the linear elastic buckling eigenvalues based on the theoretical equation, and obtain the calculated buckling coefficient and buckling displacement;

[0047] k) Assuming that the total length of the blade is H, the distance from the hub is H / 2( figure 1 (b)), H / 4 and 3H / 4 are equipped with static stator systems, and the dynamic characteristics and buckling analysis are carried out. Finally, the fundamental frequency, ...

Embodiment 2

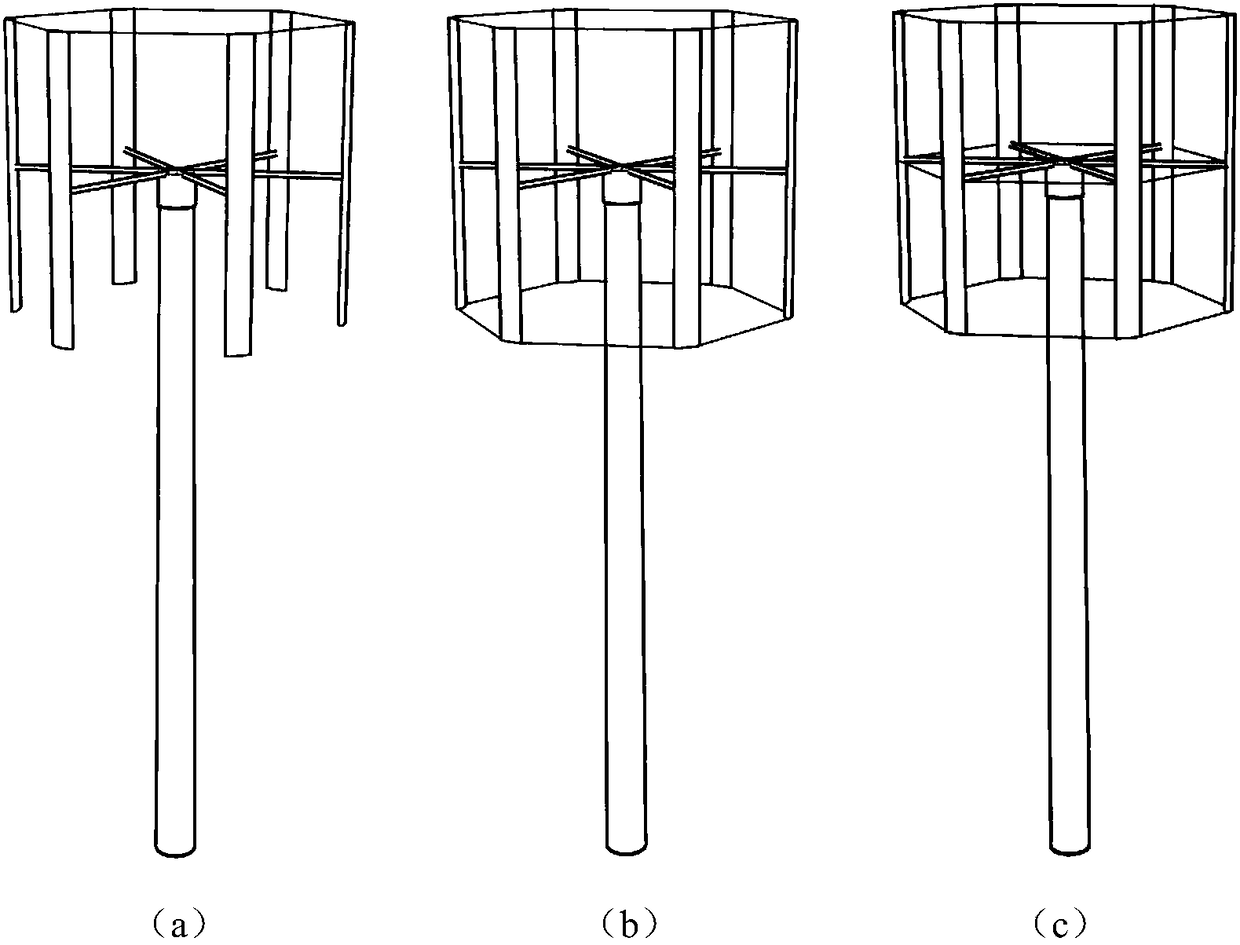

[0055] This embodiment takes a large vertical axis wind turbine in China as an example, such as figure 2 As shown, the specific implementation steps are:

[0056] i) First anchor the six cables directly to the tops of the six blades, such as figure 2 (a) A space cable system is formed, and the dynamic characteristic analysis is carried out on this basis to obtain the fundamental frequency of the wind turbine system;

[0057] j) Establish a finite element model for the system and apply a preset wind pressure, on this basis, analyze the linear elastic buckling eigenvalues based on the theoretical equation, and obtain the calculated buckling coefficient and buckling displacement;

[0058] k) Assuming that the total length of the blade is H, it is at H and H / 2 from the top of the blade in turn ( figure 2 (b) and figure 2 (c)) The static stator system is set up, and the dynamic characteristics and buckling analysis are carried out. Finally, the fundamental frequency, buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com