Exhaust pipe having cooling and fireproof functions and applied to dangerous goods transport vehicle

A technology for transportation of dangerous goods and exhaust pipes, which can be used in exhaust devices, mufflers, engine components, etc., and can solve problems such as hidden safety hazards and falling fire caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

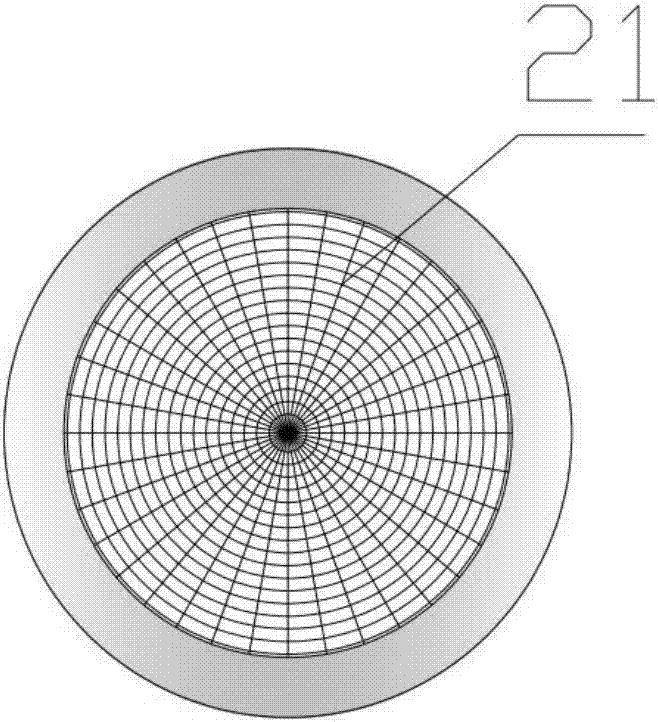

[0025] See attached Figure 1-6 , an exhaust pipe of a dangerous goods transport vehicle with the function of cooling and fire prevention, comprising three parts: an exhaust pipe 1, a fireproof filter 2 and a fireproof cooler 4; the fireproof filter 2 is placed inside the exhaust pipe 1, and the exhaust pipe 1 is placed In the internal cavity of the fire-proof cooling device 4; the right end of the exhaust pipe 1 is provided with a platform, the fire filter 2 is placed in the exhaust pipe 1, and the left end is close to the platform in the exhaust pipe 1, between the platform and the An elastic gasket 5 is arranged in the middle of the fireproof filter 2; the fireproof cooler 4 is placed outside the exhaust pipe 1, and a coolant inlet 41 is arranged above the left end of the fireproof cooler 4, and a coolant outlet 42 is arranged above the right end. The cooling liquid inlet 41 and the cooling liquid outlet 42 communicate through the cooling liquid channel 43, and the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com