Highly-deviated well casing pipe pre-filling filter sand pipe and sand prevention method

A technology of highly deviated wells and sand filter tubes, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as the inability to guarantee the compactness of pre-packing, the natural settlement of the gravel layer, and the generation of voids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8

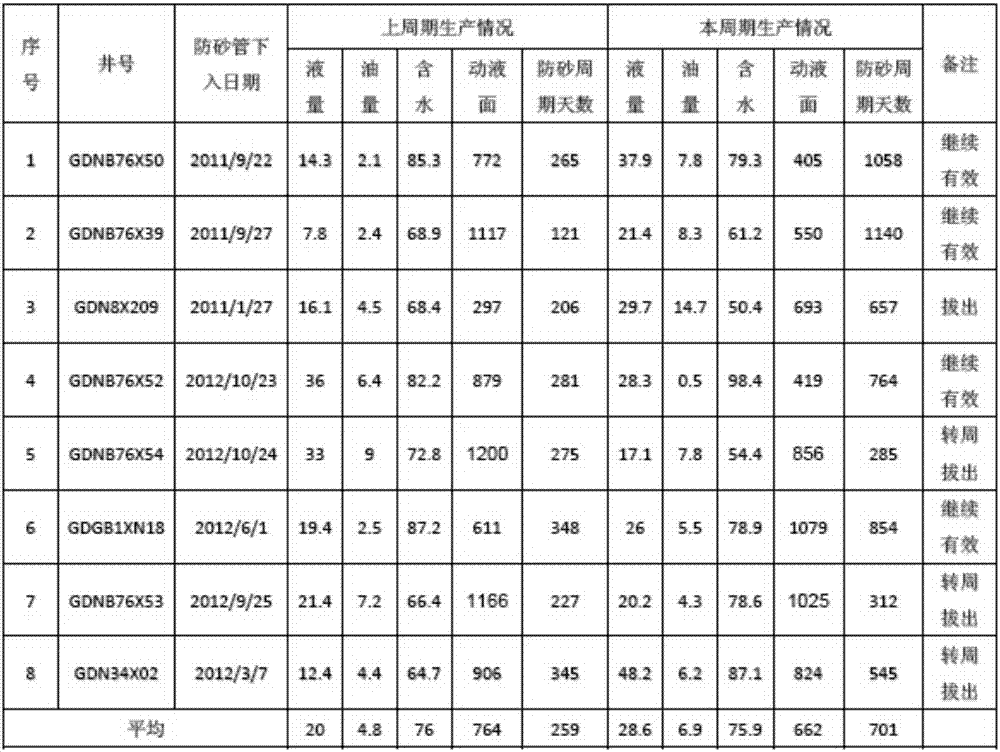

[0040] Eight wells were implemented in advance, with a maximum well deviation of 49.5° and an average of 43.8°, distributed in peripheral blocks such as Bo 76, Bo 89, Gunan 4, and Guqi 9. Compared with the previous sand control steam injection cycle or adjacent wells in the same layer, the liquid volume increased by 8.6 cubic meters, an increase of 43%. The production cycle has increased significantly, and the average 701 days has been extended by 442 days, and 4 wells continue to be effective.

[0041] Through the list of examples above: choose a few to illustrate:

Embodiment 1

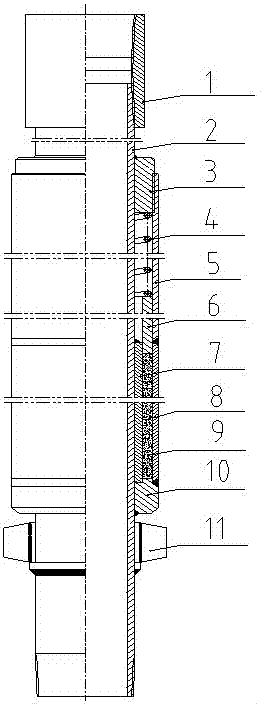

[0043] A sand control method for casing pre-packed sand filter pipes in highly deviated wells, the steps of which are as follows:

[0044] a. Obtain the physical parameters of the oil layer in the production layer, mainly including the median particle size, shale content, and sorting coefficient; for example, if Well GDN8X209 is selected, the formation cement is mainly shale, and the shale content is 11.3%; the median particle size is 0.11mm; The selection factor is 1.7, the sorting is medium, the porosity is 34.2%, and the average air permeability is 1502×10 -3 um 2 , the cementation type is pore contact type; the wettability of the oil layer is strongly hydrophilic.

[0045] b. According to the principle of moderate sand control, determine the sand-retaining accuracy of the sand filter tube, and then determine the parameters of the pre-filled ceramsite and the parameters of the inner and outer wire-wound screen pipes; The outer diameter of the inner wire-wound screen is 10...

Embodiment 2

[0052] A sand control method for casing pre-packed sand filter pipes in highly deviated wells, the steps of which are as follows:

[0053] a. Obtain the physical parameters of the oil layer in the production layer, mainly including the median particle size, shale content, and sorting coefficient; for example, if Well GDN8X209 is selected, the formation cement is mainly shale, and the shale content is 11.3%; the median particle size is 0.14mm; The selection factor is 1.7, the sorting is medium, the porosity is 34.2%, and the average air permeability is 1502×10 -3 um 2 , the cementation type is pore contact type; the wettability of the oil layer is strongly hydrophilic.

[0054] b. According to the principle of moderate sand control, determine the sand-retaining accuracy of the sand filter pipe, and then determine the parameters of the pre-filled ceramsite and the parameters of the inner and outer wire-wound screen pipes; The outer diameter of the inner wire-wrapped screen is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com