Magnetron sputtering glancing angle deposition coating device

A technology of inclined deposition and coating device, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of prolonging the experimental period, affecting the experimental efficiency, time-consuming and labor-intensive, etc., to increase the experimental possibility. The effect of changing parameters, avoiding vacuum operation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

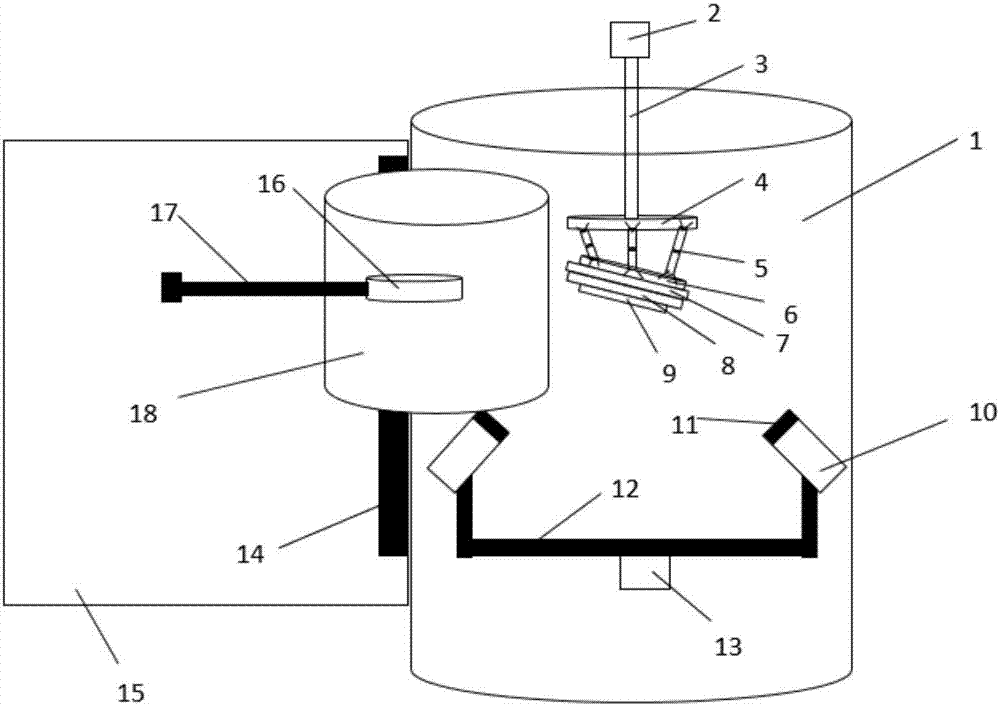

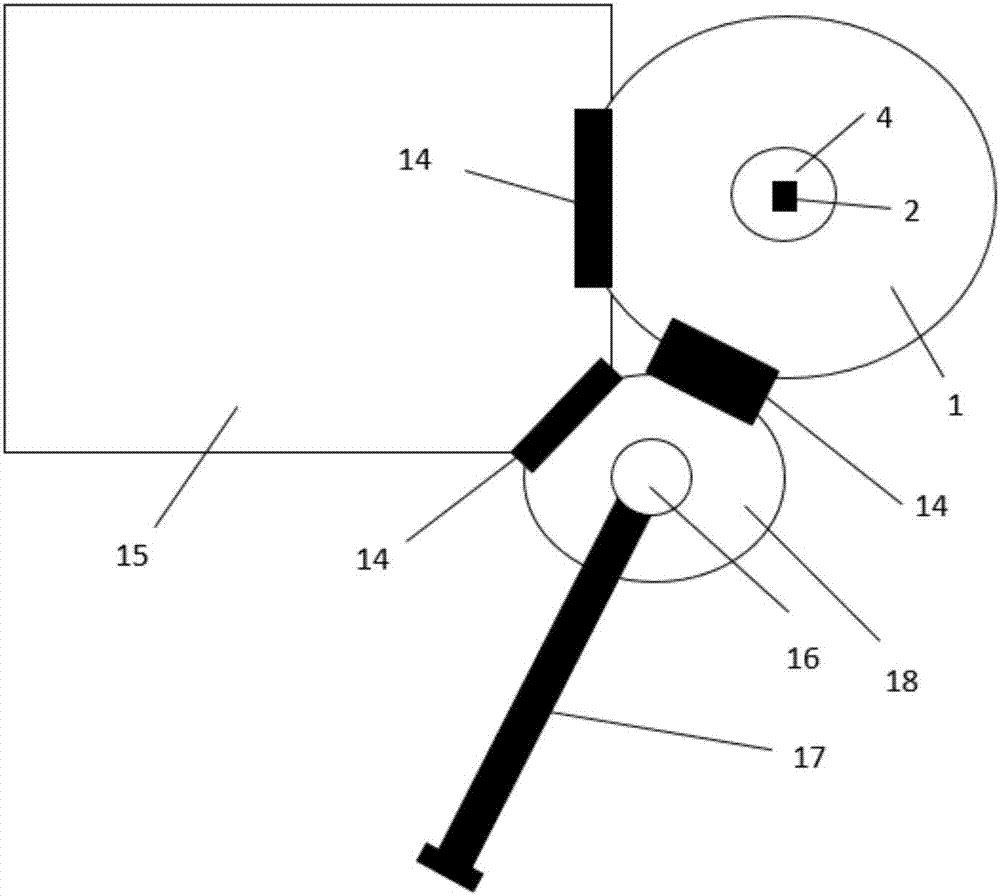

[0024] During multi-target co-sputtering experiments:

[0025] 1. Put the target material 11 into the glove box 15, open the chamber door 14 between the glove box 15 and the sputtering chamber 1, and install the target material 11 on the top of the target gun 10;

[0026] 2. Adjust and fix the position and angle of the target gun 10;

[0027] 3. Put the substrate to be plated 9 into the glove box 15, open the chamber door 14 between the glove box 15 and the transition chamber 18, and place the substrate to be plated on the transfer substrate frame 16 in the transition chamber 18;

[0028] 4. Open the chamber door 14 between the transition chamber 18 and the sputtering chamber 1, and transfer the substrate 9 to the sputtering chamber 1 through the magnetic transfer device 17;

[0029] 5. Take off the substrate 9 to be plated on the transfer substrate rack 16, and install and fix it on the substrate rack 8;

[0030] 6. Close the chamber door 14 between the transition chamber 1...

Embodiment 2

[0040] During grazing incidence experiments:

[0041] 1. Put the target material 11 into the glove box 15, open the chamber door 14 between the glove box 15 and the sputtering chamber 1, and install the target material 11 on the top of the target gun 10;

[0042] 2. Adjust and fix the position and angle of the target gun 10;

[0043] 3. Put the substrate to be plated 9 into the glove box 15, open the chamber door 14 between the glove box 15 and the transition chamber 18, and place the substrate to be plated on the transfer substrate frame 16 in the transition chamber 18;

[0044] 4. Open the transition chamber 18 and the chamber door 14 of the sputtering chamber 1, and transfer the substrate 9 to the sputtering chamber 1 through the magnetic transfer device 17;

[0045] 5. Take off the substrate 9 to be plated on the transfer substrate rack 16, and install and fix it on the substrate rack 8;

[0046]6. Close the chamber door 14 between the transition chamber 18 and the sputt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com