Biochar soil conditioner and preparation method thereof

A technology of soil conditioner and biochar, which is applied in the field of agricultural chemistry, can solve the problems of improving soil physical and chemical properties, poor fertility effect, and single conditioning effect, so as to solve the problems of soil fertility loss and poor physical and chemical properties, cost saving, and sufficient raw materials. The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

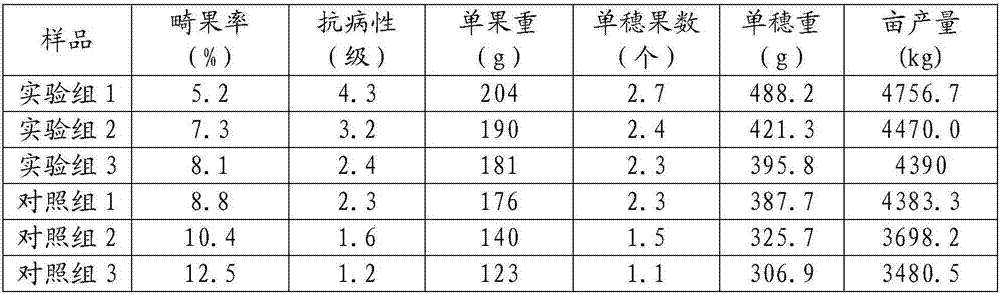

Examples

Embodiment 1

[0039] Embodiment 1: the preparation of biochar

[0040] Bake the biochar raw material in an oven at 115°C for 20 hours, and pulverize it to obtain a powdered biomass raw material with a particle size of less than 10 cm; raise the temperature of the powdered biomass raw material from normal temperature to 300 °C at a rate of 30 °C / min under anaerobic conditions. ℃, keep warm for 2h, then raise the temperature to 900°C at a rate of 10°C / min, and maintain the temperature for 3h to pyrolyze and carbonize the powdered biomass raw material to obtain unactivated biochar; add 2mol Soak in / L potassium hydroxide, activate for 3-5h, wash at least 3 times with hot water at 80°C and distilled water at room temperature, then soak the biochar in 4mol / L phosphoric acid solution, activate for 3-5h, and wash at 80°C Wash with hot water and distilled water at normal temperature for at least 3 times, dry and pulverize until the particle size is less than 1 mm to obtain biochar.

Embodiment 2

[0041] Embodiment 2: the preparation of biochar

[0042] Bake the biochar raw material in an oven at 115°C for 20 hours, and pulverize it to obtain a powdered biomass raw material with a particle size of less than 10 cm; raise the temperature of the powdered biomass raw material from normal temperature to 300 °C at a rate of 30 °C / min under anaerobic conditions. ℃, keep warm for 2h, then raise the temperature to 900°C at a rate of 10°C / min, and maintain the temperature for 3h to pyrolyze and carbonize the powdered biomass raw material to obtain unactivated biochar; add 1mol Soak in / L potassium hydroxide, activate for 3-5h, wash with hot water at 80°C and distilled water at room temperature for at least 3 times, then soak the biochar in 3mol / L phosphoric acid solution, activate for 3-5h, and wash at 80°C Wash with hot water and distilled water at normal temperature for at least 3 times, dry and pulverize until the particle size is less than 1 mm to obtain biochar.

Embodiment 3

[0043] The preparation of embodiment 3 biochar

[0044] Bake the biochar raw material in an oven at 115°C for 20 hours, and pulverize it to obtain a powdered biomass raw material with a particle size of less than 10 cm; raise the temperature of the powdered biomass raw material from normal temperature to 300 °C at a rate of 30 °C / min under anaerobic conditions. ℃, keep warm for 2h, then raise the temperature to 900°C at a rate of 10°C / min, and maintain the temperature for 3h to pyrolyze and carbonize the powdered biomass raw material to obtain unactivated biochar; add 0.5 Soak in mol / L potassium hydroxide, activate for 3-5 hours, wash with hot water at 80°C and distilled water at room temperature for at least 3 times, then soak the biochar in 2mol / L phosphoric acid solution, activate for 3-5 hours, and wash at 80°C Wash with hot water and distilled water at room temperature at least 3 times, dry and pulverize until the particle size is less than 1 mm to obtain biochar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com