Sewage treatment equipment for production and manufacturing

A technology of sewage treatment equipment and water inlet pool, which is applied in the fields of neutralization water/sewage treatment, water/sludge/sewage treatment, water treatment parameter control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

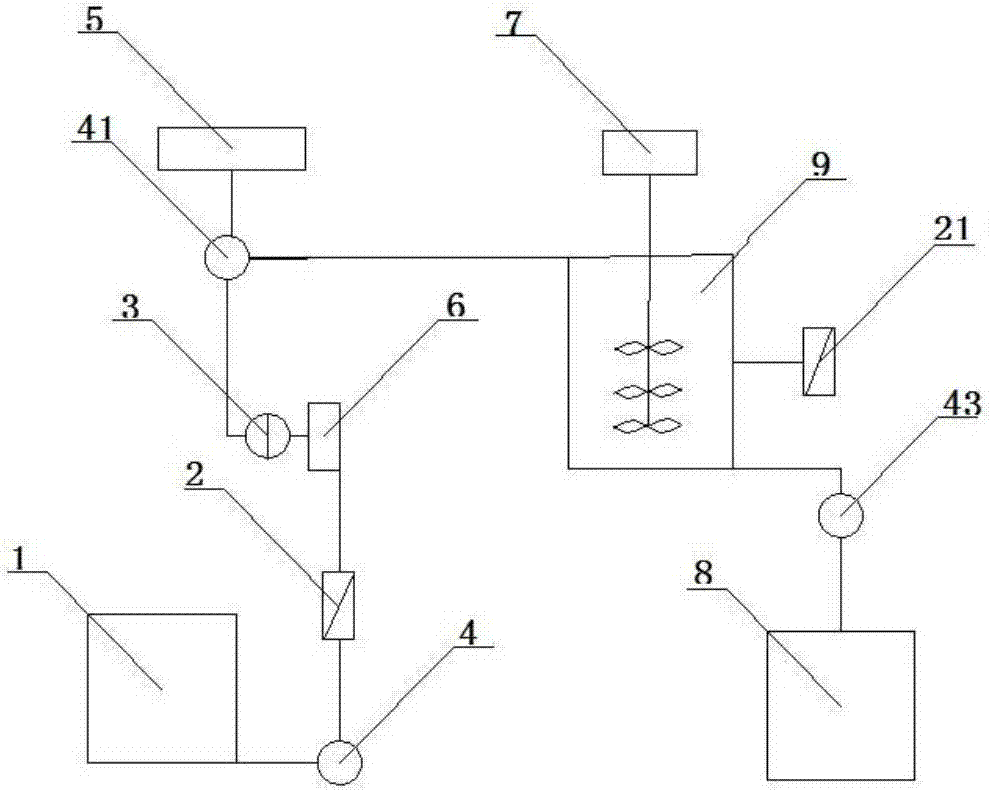

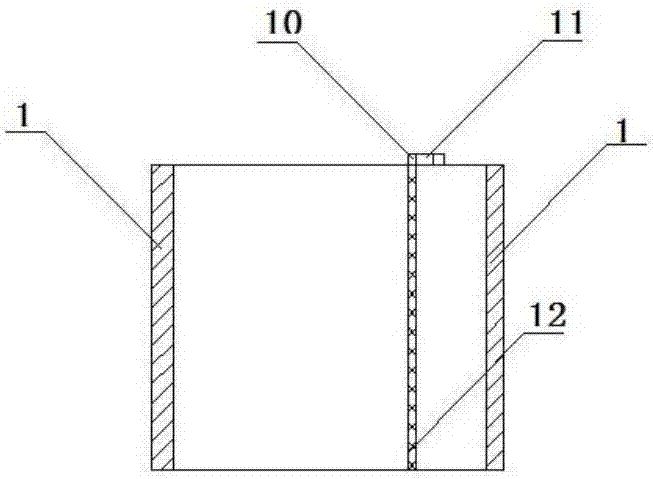

[0022] Such as figure 1 As shown, the present invention is a kind of sewage treatment equipment used for production, including a water inlet pool 1, and the water inlet pool 1 is connected to the first solenoid valve 4, the first PH detector 2, the meter 6, and the one-way valve in sequence through pipelines. 3. Stirring container 9 and water outlet tank 3, wherein, a second solenoid valve 41 is set between the check valve 3 and the stirring container 9, the second solenoid valve 41 is connected to the chemical container 5, and the stirring container 9 is provided with a stirring device and a second pH meter 21. The stirring device 7 includes a motor and blades. A filter screen 12 is arranged inside the water inlet pool 1 , and the top of the water inlet pool 1 includes a slide groove 11 matching the filter screen 12 . The sliding groove 11 is provided with card positions 10, and the number of the card positions 10 is two. When working: first, the electromagnetic valve is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com