Discharge unit, welding device with discharge unit and welding method

A welding device and welding method technology, used in electric heating devices, tin feeding devices, auxiliary devices, etc., can solve the problems of easy burn-through of component pins, and achieve fast and continuous welding process, low failure rate, and quality assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

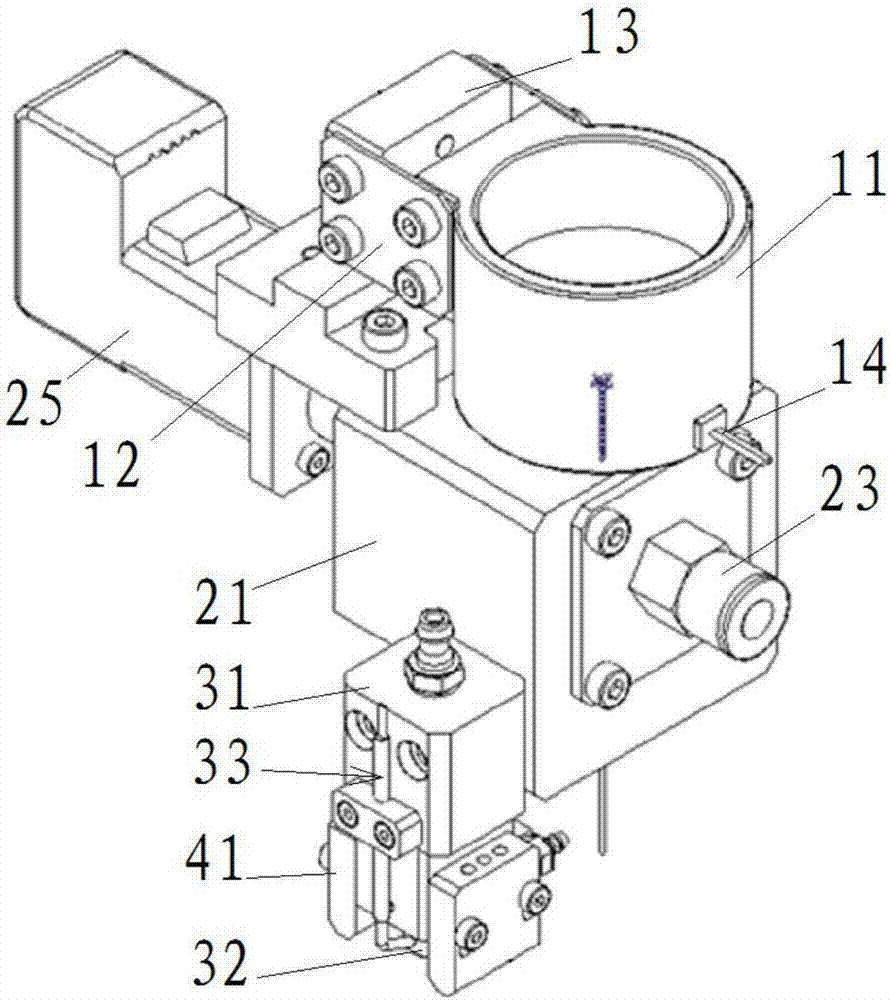

[0067] Such as figure 1 As shown, according to an embodiment of the present invention, the welding device includes: a storage unit 1 , a transfer unit 2 , a discharge unit 3 and a shielding gas unit 4 . In this embodiment, the storage unit 1 is located above the transfer unit 2 , and the discharge unit 3 is located below the transfer unit 2 . The storage unit 1 , the transfer unit 2 and the discharge unit 3 are detachably connected to each other. The above-mentioned units are detachably connected, which facilitates the replacement and maintenance of each unit, improves the versatility and service life of the present invention, and reduces the cost of the present invention.

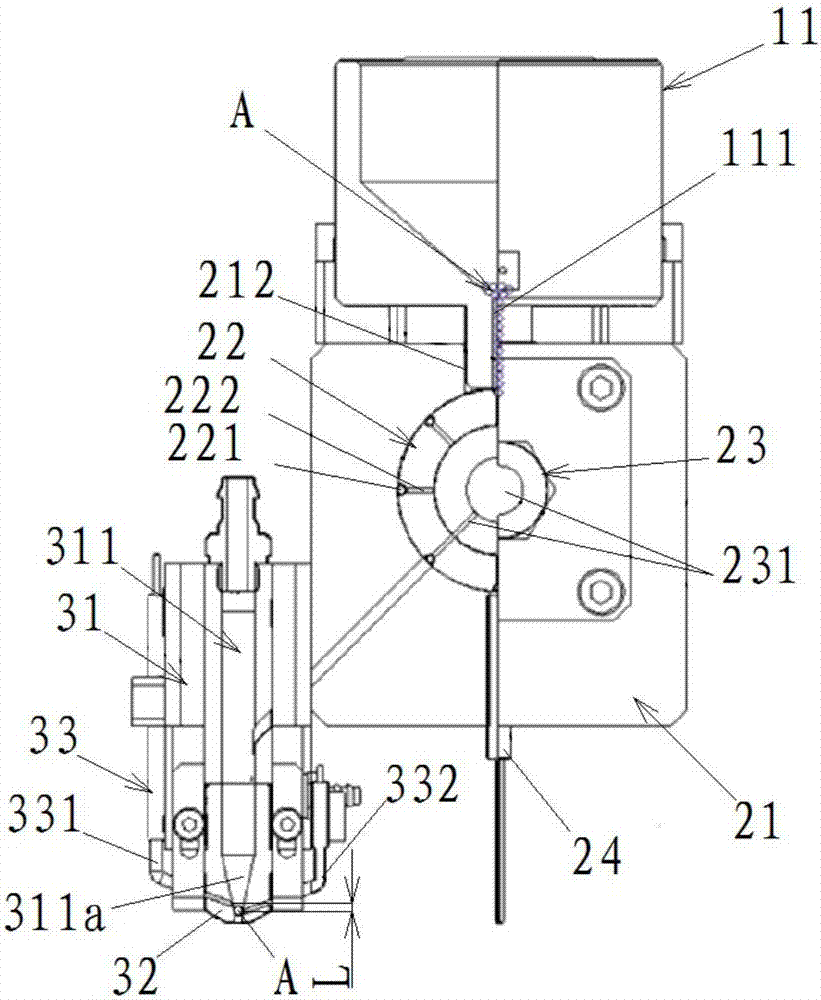

[0068] figure 2 It is a perspective view which schematically shows the welding apparatus which concerns on one Embodiment of this invention.

[0069] combine figure 1 and figure 2 As shown, according to an embodiment of the present invention, the storage unit 1 includes a storage bin 11 , an elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com