Organic solvent dehydration equipment of pervaporation membrane

A technology of permeating gasification membranes and organic solvents, applied in the field of medicine and chemical industry, can solve the problems of inability to achieve the effect of recycling and water extraction, and achieve the effects of improving comprehensive utilization benefits, compensating for the heat loss of airflow, and reducing entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

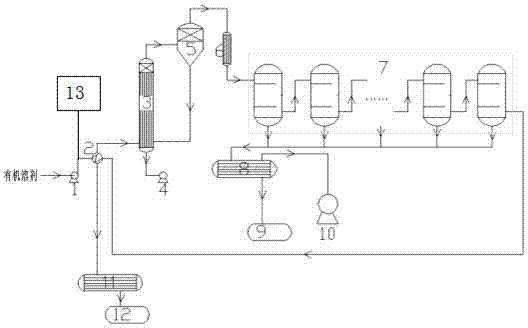

[0015] A pervaporation membrane organic solvent dehydration equipment, comprising a raw material pump 1, a preheater 2, an evaporator 3, a raffinate pump 4, a gas-liquid separator 5, a superheater 6, a dehydration device 7, a permeate receiving tank 9, The vacuum unit 10, the finished product condenser 11, and the finished product tank 12; the raw material pump 1, the preheater 2, the evaporator 3, the gas-liquid separator 5, the superheater 6, and the dehydration device are sequentially connected by pipelines; the bottom of the evaporator 3 Connected to the raffinate pump 4 pipelines; described; the bottom of the dehydration device is provided with a permeate condenser 8, and the permeate condenser 8 is connected to the permeate receiving tank 9 and the vacuum unit 10 respectively; the dehydration device passes through The preheater 2 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com