Planting technology of alfalfa in saline and alkaline land

A technology of alfalfa and planting technology, applied in land preparation methods, botanical equipment and methods, horticulture, etc., can solve the problems of deterioration of soil structure, high concentration of soil solution, difficult utilization of soil resources, etc., and achieve considerable economic and social benefits. , the effect of improving land quality and improving soil utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

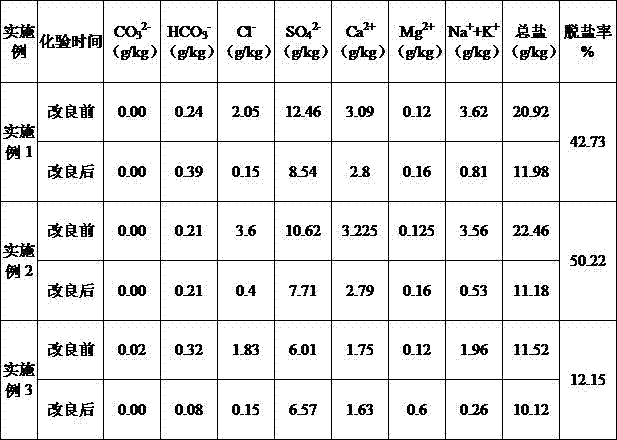

Embodiment 1

[0016] Embodiment 1: A kind of alfalfa planting technology in saline-alkali land

[0017] (1) Pretreatment of saline-alkali land: Because of the surface accumulation of soil salt in saline-alkali land, alkali pockets are formed on the ground surface, resulting in crop seedling shortage. Therefore, salt washing and alkali removal treatment must be carried out before sowing. The specific method of salt washing and alkali removal treatment is to treat the After the land is plowed to a depth of 30cm, it is fully irrigated with water every ten days, and the amount of water per irrigation is 260m 3 per mu, and the surface water storage must be kept not less than 20cm, so repeat irrigation 3 times; after treatment, keep the soil mature and wait for sowing;

[0018] (2) Sowing: Before sowing, it is necessary to fertilize according to the base fertilizer standard of 48kg of superphosphate, 8kg of diammonium phosphate, 20kg of phosphorus nitrate, 15kg of potassium sulfate, and 30kg of a...

Embodiment 2

[0021] Embodiment 2: a kind of alfalfa planting technology in saline-alkali land

[0022] (1) Pretreatment of saline-alkali land: Because of the surface accumulation of soil salt in saline-alkali land, alkali pockets are formed on the ground surface, resulting in crop seedling shortage. Therefore, salt washing and alkali removal treatment must be carried out before sowing. The specific method of salt washing and alkali removal treatment is in late July After deep plowing of 35cm to the land, fully irrigate once every ten days, and the amount of water per irrigation is 280m 3 per mu, and the surface water must be kept not less than 22.5cm, so repeated irrigation 4 times; after treatment, keep the soil mature and ready for sowing;

[0023] (2) Sowing: Before sowing, it is necessary to fertilize according to the base fertilizer standard of 51kg of superphosphate, 10kg of diammonium phosphate, 22.5kg of phosphorus nitrate, 17.5kg of potassium sulfate, and 32.5kg of Angel yeast. Th...

Embodiment 3

[0026] Embodiment 3: a kind of alfalfa planting technology in saline-alkali land

[0027] (1) Pretreatment of saline-alkali land: Because of the surface accumulation of soil salt in saline-alkali land, alkali pockets are formed on the ground surface, resulting in crop seedling shortage. Therefore, salt washing and alkali removal treatment must be carried out before sowing. The specific method of salt washing and alkali removal treatment is to treat the After the land is plowed to a depth of 40cm, it is fully irrigated with water every ten days, and the amount of water per irrigation is 300m 3 per mu, and the surface water storage must be kept not less than 25cm, so repeat irrigation 5 times; after treatment, keep the soil mature and wait for sowing;

[0028] (2) Sowing: Before sowing, it is necessary to fertilize according to the base fertilizer standard of 54kg of superphosphate, 12kg of diammonium phosphate, 25kg of phosphorus nitrate, 20kg of potassium sulfate, and 35kg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com