A Visual Inspection Method for Defect Detection of Anti-vibration Hammer

A defect detection and visual inspection technology, used in image analysis, image enhancement, instruments, etc., can solve the problems of research on the defect detection of anti-vibration hammer, it cannot be used well, and it is not universal and accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

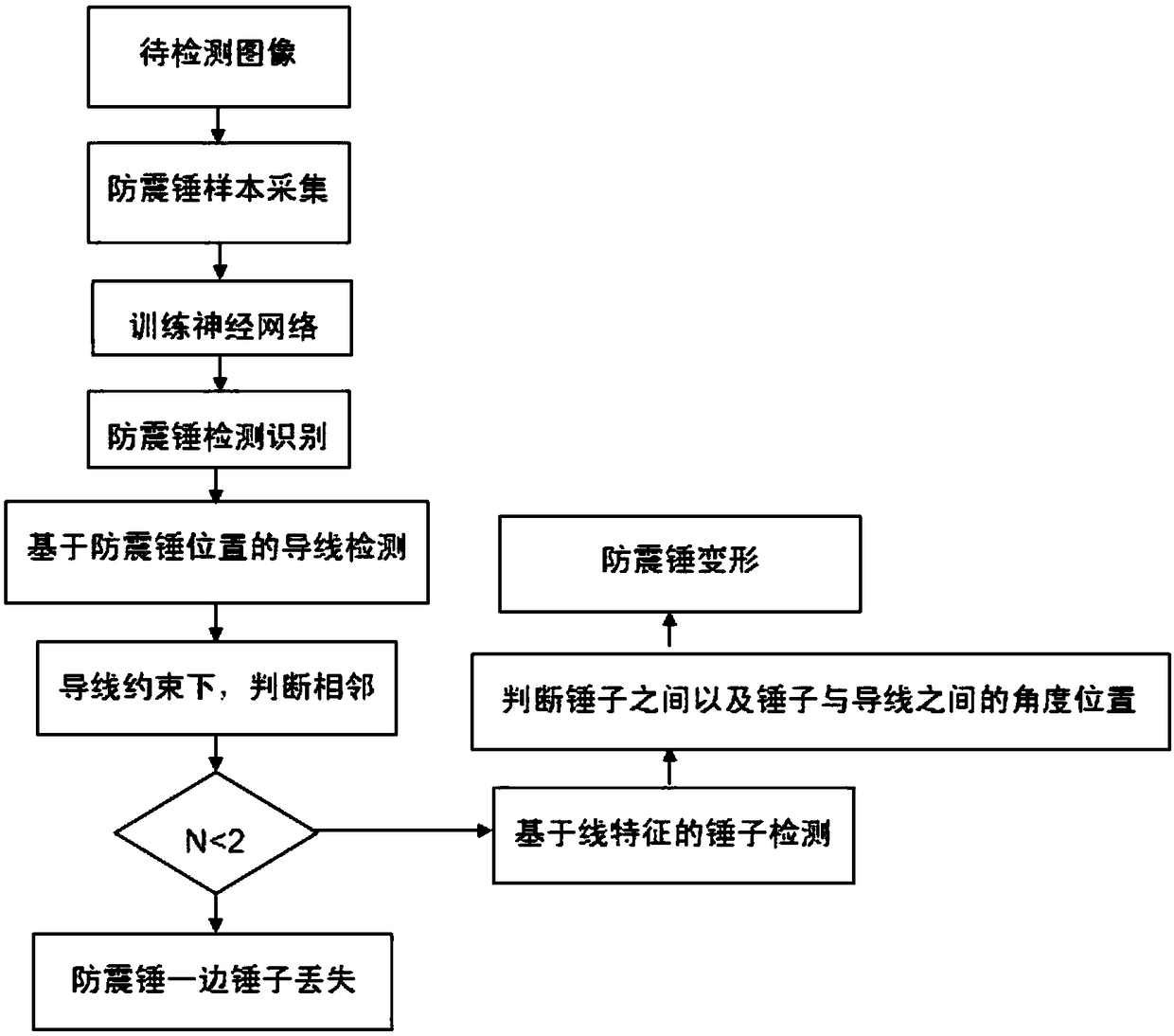

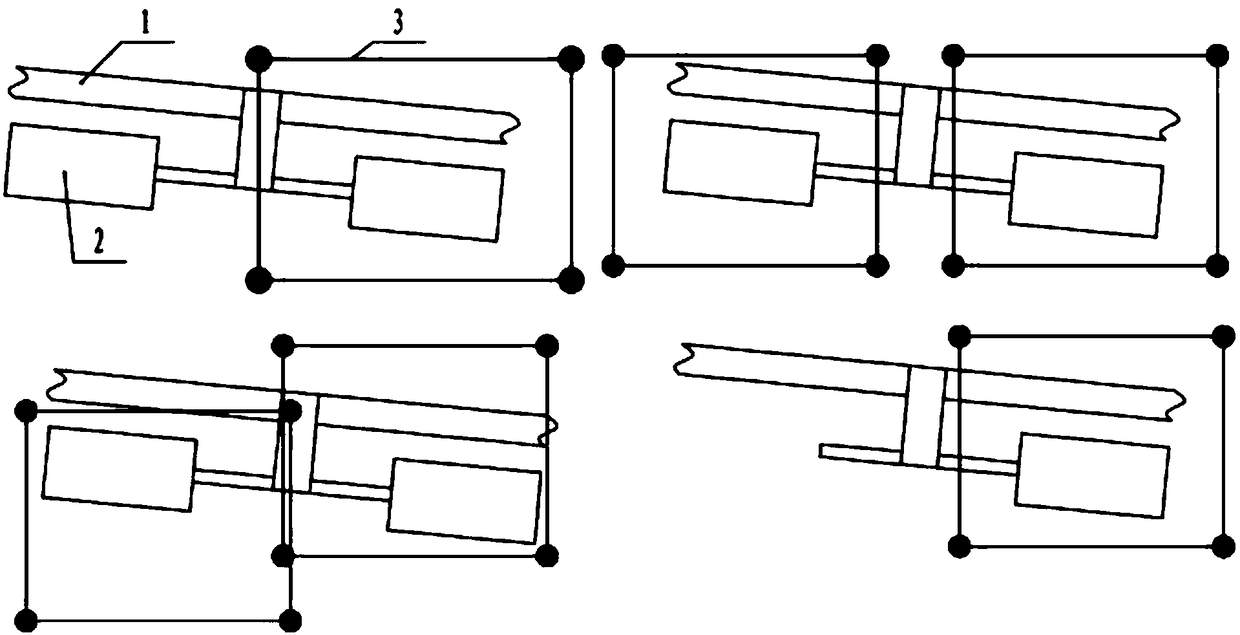

[0066] Example: such as Figure 1-4 Shown, a kind of visual detection method of antivibration hammer defect detection, this method comprises the following steps:

[0067] Step 1. Preprocess the transmission line images collected by the UAV, detect whether there are quality problems in the captured images, and perform denoising and anti-shake operations on the data;

[0068] Step 2, data expansion, before sample collection, first perform data expansion on the preprocessed data in step 1 to generate similar images;

[0069] Step 3, collect samples: Use the method of collecting one side of the anti-vibration hammer to sample the image sample expanded in step 2. During the sample collection process, ensure that there are more than 500 different types of anti-vibration hammers and more than 500 different anti-vibration hammer bodies. The total number is not less than 4000;

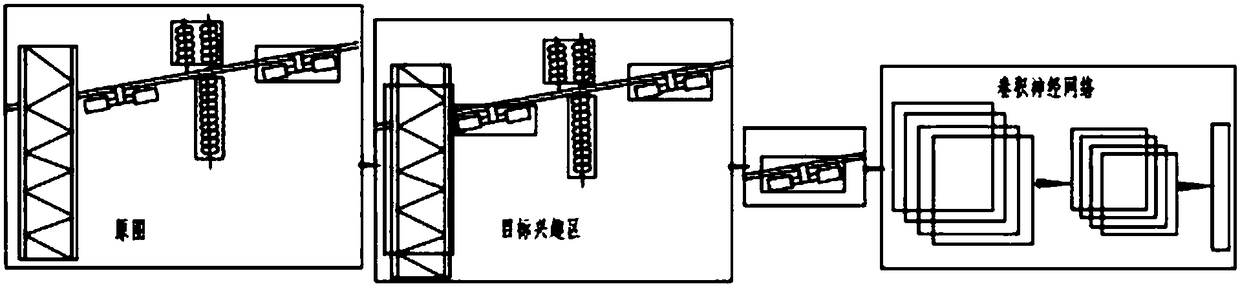

[0070] Step 4, determine the area selection to be trained, use the information of the image segmentation t...

Embodiment 2

[0111] Embodiment 2: a kind of visual detection method of antivibration hammer defect detection, this method comprises the following steps:

[0112] Step 1: First, preprocess the aerial images of the UAV. Since the aerial image collection by aircraft inspection is carried out in the natural environment in the field, the image is very seriously affected by noise and motion blur during the acquisition process, resulting in serious image degradation, that is, distortion, blur, distortion or distortion in the imaging process. The noise is mixed in, resulting in a decline in image quality. At the same time, due to the limitation of lighting conditions, poor exposure (under or over) and uneven brightness of the image screen are caused during photography. Therefore, it is important to analyze and detect the collected aerial images. The most important link is the preprocessing of aerial images. The purpose of aerial image preprocessing is to use a series of technical means to improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com