Totally-enclosed type spherical all-directional gyroscope mechanism and operation method thereof

A fully enclosed, spherical technology, applied in the direction of rotating gyroscope, etc., can solve the problems of external equipment and instruments, personal danger, damage to its own rotor, etc., to achieve good transmission effect, compact structure, and maintain the effect of transmission effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the embodiments shown in the drawings.

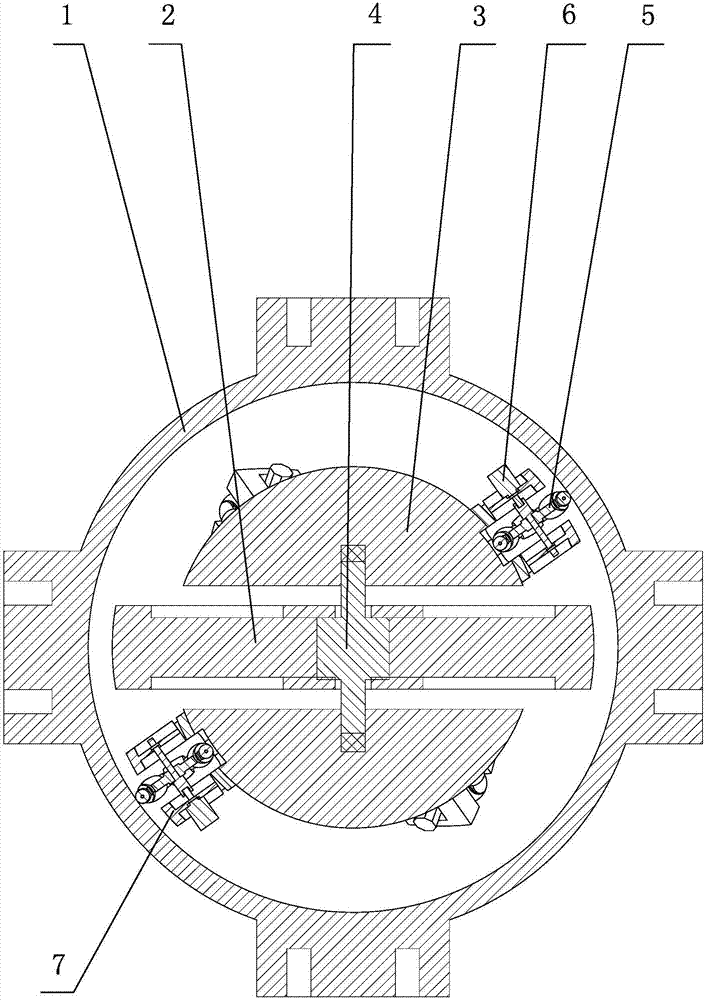

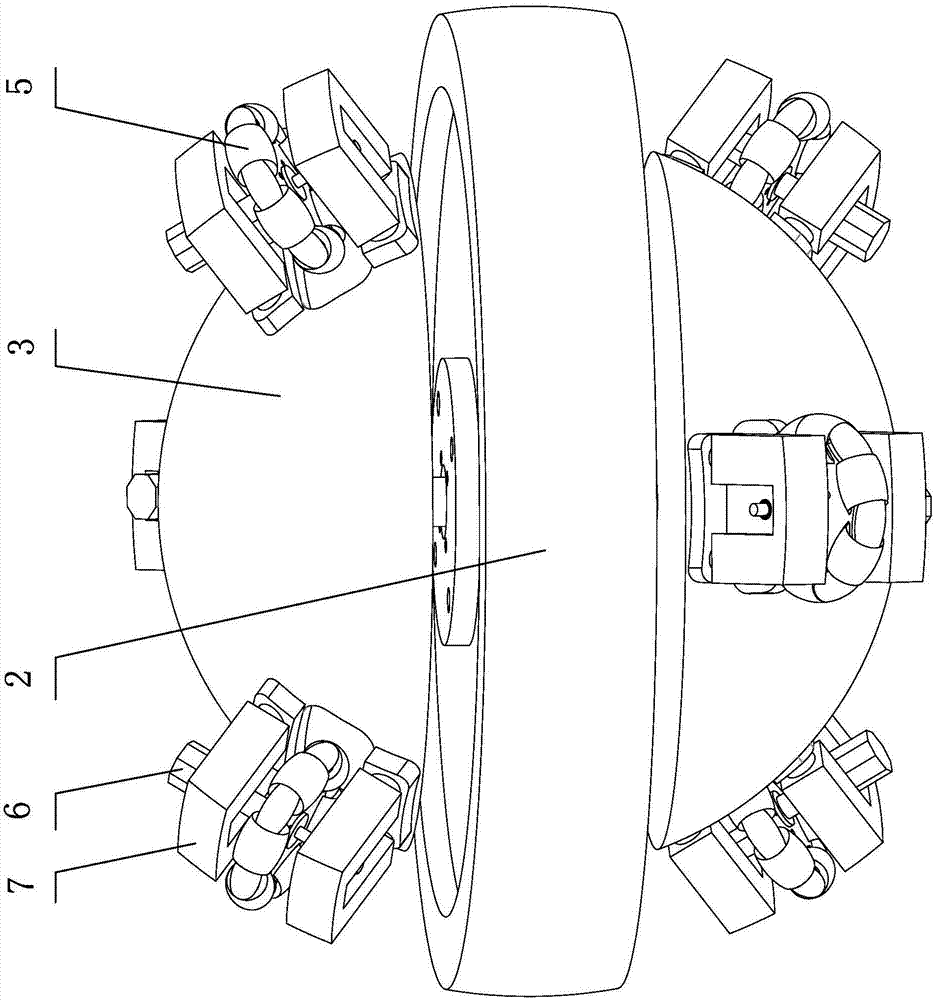

[0029] The fully enclosed spherical omnidirectional gyro mechanism of the present invention includes an outer spherical shell 1 and a horizontal rotor 2 arranged in the outer spherical shell 1, and upper and lower arc-shaped spheres 3 through which the outer spherical shell 1 passes. , Left and right square housings are installed on the equipment body, such as figure 1 Shown.

[0030] The horizontal rotor 2 is arranged at the central position inside the outer spherical shell 1, the rotation center line of the horizontal rotor 2 is on the sphere center of the outer spherical shell 1, and the upper and lower arc-shaped spheres 3 are respectively arranged above and below the horizontal rotor 2 , The sphere centers of the upper and lower arc-shaped spheres 3 are concentric with the center of the outer spherical shell 1, and there is a space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com