Etching agent for inspecting dissimilar steel welding joint structure and using method thereof

A technology of welding joints and etchant, which is applied in the preparation of test samples, etc., can solve the problems of complex display methods, large potential differences in different regions, and corrosion artifacts, so as to achieve real and stable erosion effects, good reproducibility, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

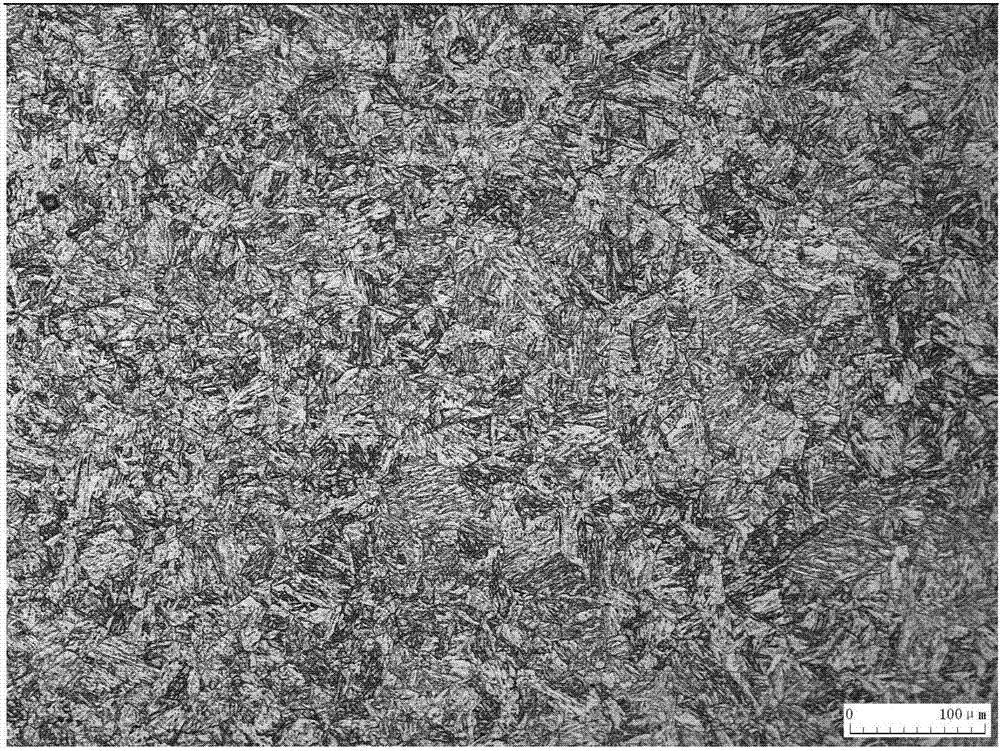

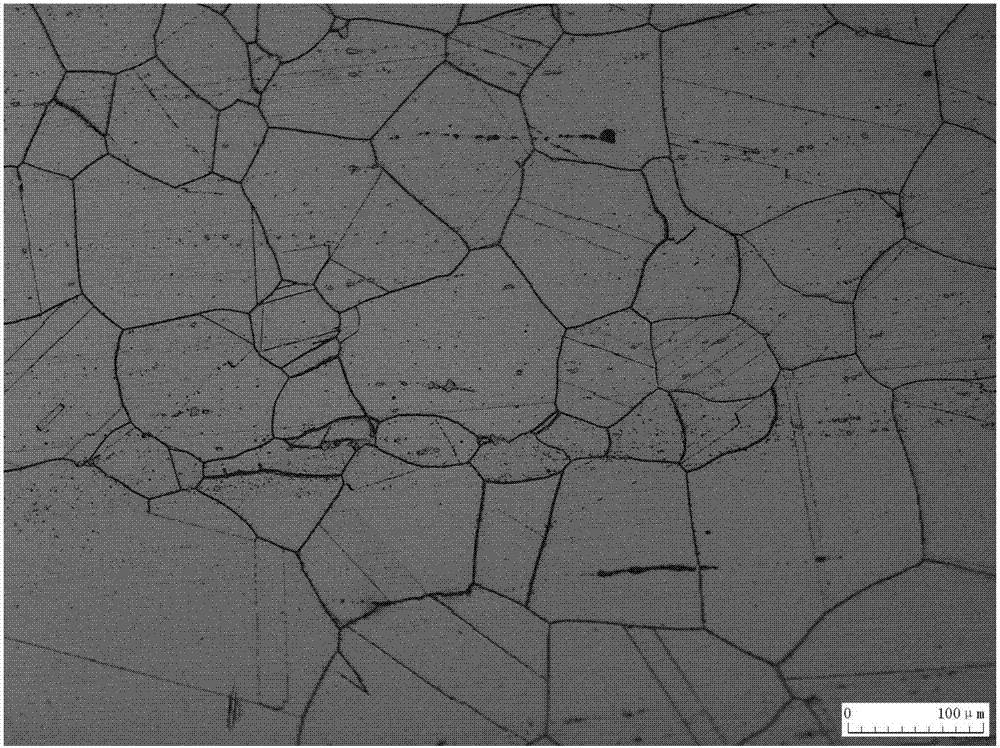

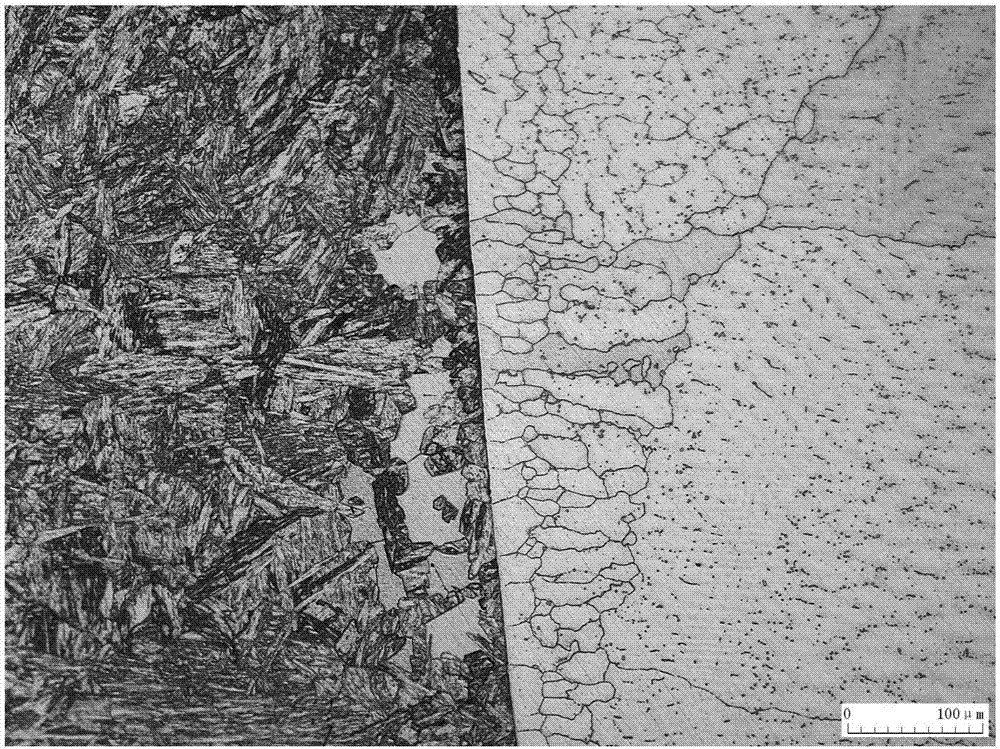

Embodiment 1

[0050] refer to Figure 1-5 shown, where image 3 , 4 The middle left area is the heat affected zone, and the right area is the weld area. The microstructure of each area of the welded joint of SA-213T92 and TP310HCbN heat-resistant stainless steel can be displayed clearly, completely and without artifacts through one-time corrosion by using ferric chloride-sodium chloride-nitric acid-phosphoric acid solution etchant , so as to accurately carry out the metallographic inspection of the joint. The method of the invention is simple, convenient, fast and safe to operate, the etching agent can be placed for a long time, the display effect is stable, and the reproducibility is good, and mainly includes the following contents:

[0051] 1. The composition of the mass percentage of the etchant:

[0052] (1) 1% ferric chloride (analytical pure);

[0053] (2) 1% sodium chloride (analytical grade)

[0054] (3) 26% concentrated nitric acid (analytical pure);

[0055] (3) 72% phosp...

Embodiment 2

[0062] refer to Figure 6-10 shown, where Figure 8 , 9 The middle left area is the weld area, and the right area is the heat affected zone. This example is basically the same as Example 1, the difference is that the etchant is used to test the structure of the welded joint of SA-213T91 and S30432 heat-resistant stainless steel dissimilar steel, and the mass percentage of the etchant is composed of:

[0063] (1) 2% ferric chloride (analytical pure);

[0064] (2) 3% sodium chloride (analytical grade)

[0065] (3) 15% concentrated nitric acid (analytical grade);

[0066] (3) 80% phosphoric acid (analytical grade).

Embodiment 3

[0068] refer to Figure 11-15 shown, where Figure 13 , 14 The middle left area is the heat affected zone, and the right area is the weld area. This example is basically the same as Example 1, the difference is that the etchant is used to test the structure of the welded joint of SA-213T91 and TP347HFG heat-resistant stainless steel dissimilar steel, and the mass percentage of the etchant is composed of:

[0069] (1) 5% ferric chloride (analytical pure);

[0070] (2) 6% sodium chloride (analytical grade)

[0071] (3) 12% concentrated nitric acid (analytical pure);

[0072] (3) 77% phosphoric acid (analytical grade).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com