Alloying hot-dip galvanized steel of which tensile strength is greater than or equal to 780MPa and production method of alloying hot-dip galvanized plate

A tensile strength and alloying technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of substandard mechanical properties, poor platability of high-strength steel, etc., and achieve good platability and , the effect of good coating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below:

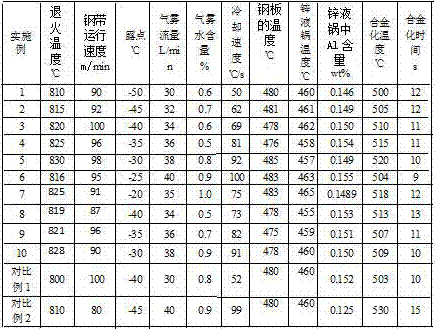

[0041] Table 1 is the component value list of each embodiment of the present invention and comparative example;

[0042] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0043] Table 3 is a list of the mechanical performance testing of each embodiment of the present invention and comparative examples.

[0044] Each embodiment of the present invention is produced according to the following steps:

[0045] 1) After conventional hot rolling, cooling, crimping, pickling and cold rolling;

[0046] 2) Carry out continuous annealing, and control the annealing temperature at 810-830°C, and the running speed of the steel strip at 80-100m / min; and control the dew point at -50--20°C;

[0047] 3) Use air mist cooling to lower the temperature to the hot-dip galvanizing temperature, wherein the water weight percentage in the cooling air mist is controlled at 0.5-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com