A kind of environment-friendly rubber oil and preparation method thereof

An environmentally friendly rubber oil and rubber oil technology, applied in the field of petrochemical industry, can solve the problems of relatively harsh operating conditions, poor compatibility between rubber oil and rubber, and more loss of aromatics content, and achieve high CN value and low pour point , the effect of high aromatic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

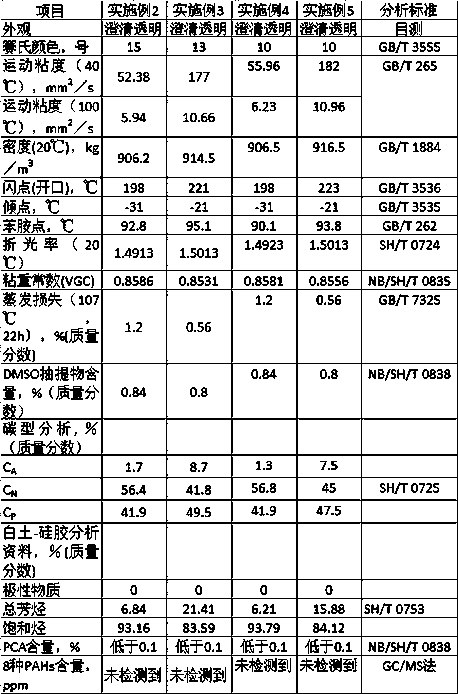

Examples

Embodiment 1

[0020] Example 1 Preparation of naphthenic base oil

[0021] The viscosity is 6.5~16.0mm 2 / s (100°C), fractions of unsaturated chain hydrocarbons and monocyclic and polycyclic aromatic hydrocarbons with a distillation range of 350~480°C (in this fraction, fractions of unsaturated chain hydrocarbons and monocyclic and polycyclic aromatic hydrocarbons account for the total weight of the fractions) 30~55% of ) as raw material, through the hydrotreating reactor, the reaction temperature is 320~380℃, the reaction pressure is 15~17MPa, the reaction hydrogen oil volume ratio is 1000~3000, and the space velocity is 0.2~0.6 / h ; Then through the dewaxing reactor, the reaction temperature is 350~390℃, the reaction pressure is 15~17MPa, the reaction hydrogen oil ratio is 1000~3000, and the space velocity is 1.5~4 / h; and then through the hydrofining reactor, During the reaction process, the reaction temperature is 230~270℃, the reaction pressure is 15~17MPa, the reaction hydrogen oil rat...

Embodiment 2

[0026] Raw material ratio: in terms of mass percentage, 3-ring methyl polybenzyltoluene derivative Friedel-Craftene 100 (FC0100) (purchased from Shanghai Zexi Chemical Technology Co., Ltd., the team of Fu Ke-Xi, Fu Ke-Xi, China) 10%, optical Thermal composite stabilizer (UV light absorber and heat stabilizer mixed at 1:1, stored in an oven at 60°C for 48 hours before use) accounted for 0.04%, and the balance was the viscosity prepared in Example 1 (100°C) 6cSt naphthenic base oil.

[0027] According to the above weight ratio, the 3-ringmethylpolybenzyltoluene derivative is added to the naphthenic base oil, and the mixture is uniformly stirred at 800 rpm at 50-80° C. for 0.5 h. Then heat up to 100°C, add photothermal composite stabilizer, and stir evenly at 500 rpm for 0.3h to obtain the green rubber oil.

Embodiment 3

[0029] In this embodiment, the preparation method of naphthenic base oil is the same as that in Embodiment 1.

[0030]The difference from Example 1 is that in the raw material of color-friendly rubber oil prepared in this example, in terms of mass percentage, 3-ringmethyl polybenzyl toluene derivative Friedel-Crossene 100 (FC0100) accounts for 10%, and the photothermal composite is stable agent (ultraviolet light absorber JL-900 and heat stabilizer JL-300, mixed at a mass ratio of 5:1 and stored in an oven at 60°C for 48 hours before use) accounted for 0.04%, and the others were viscosities prepared by the method in Example 1 (100°C) is a 10cSt naphthenic base oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com